High speed Ac Servo Motor 600W 1.9Nm 3000rpm and Driver for Sewing Machinery

Features

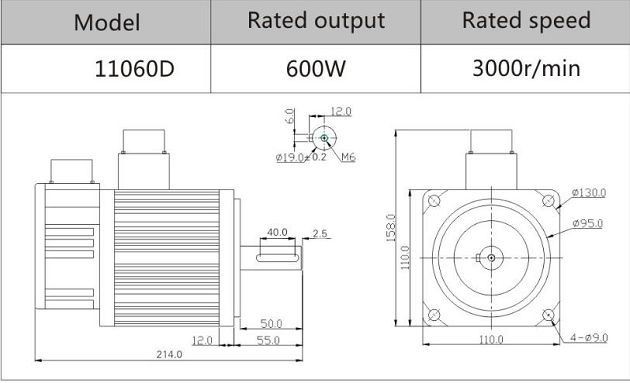

GH-11060DC is 600W servo motor , 110 frame, big load, and mataching with big servo driver, is very specially model between 400W and 750W servo motor.

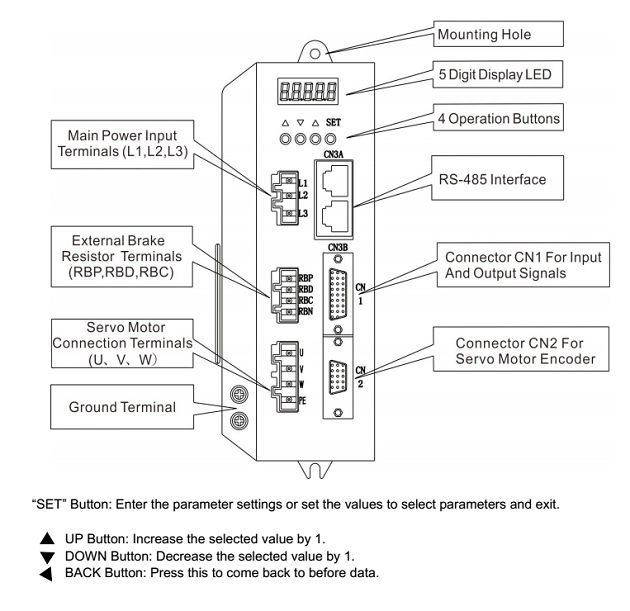

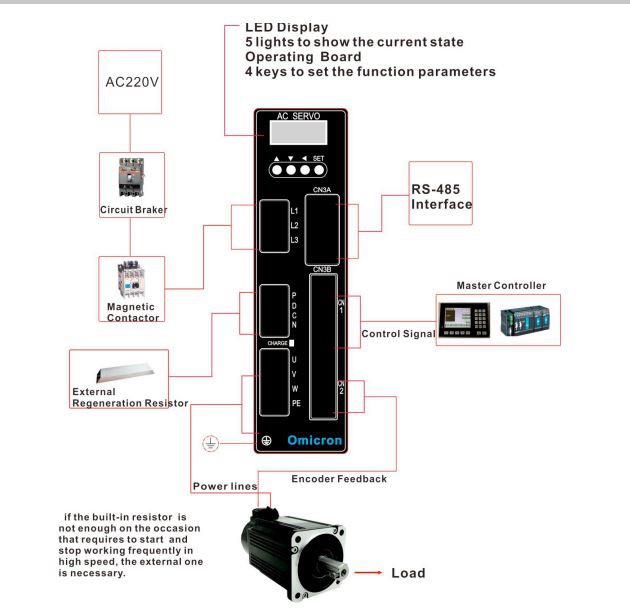

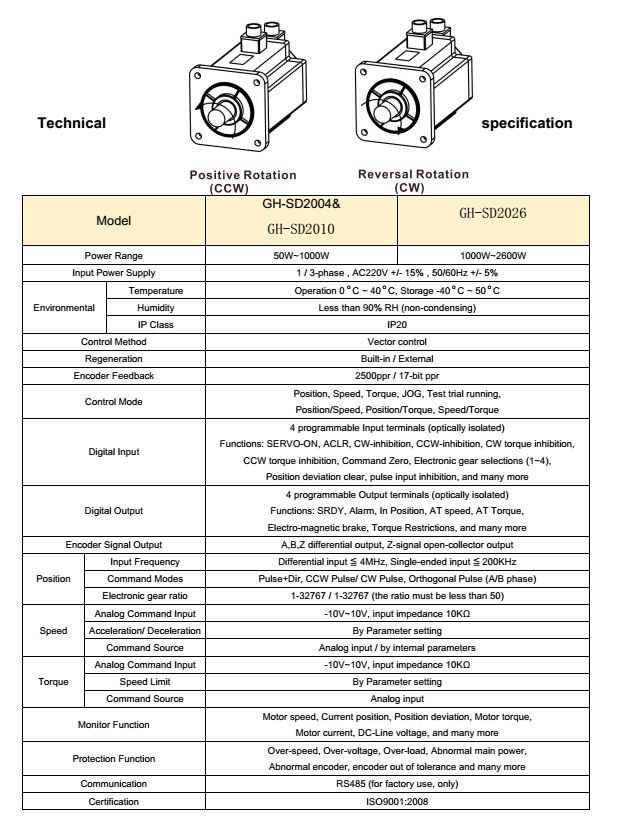

The match servo driver, GH-sd2026 ,that matching for 600W servo motor.

Application

CNC Machinery,printing equipment, packaging equipment, textile equipment, laser processing equipment,robotics, automated production lines, such as processing precision, processing efficiency and reliability, and other requirements of the relatively high equipment.

| Motor Model | SZGH-11060DC |

| Rated Power(W) | 600 |

| Rated Voltage(V) | 220 |

| Rated Crrent(A) | 2.5 |

| Rated Speed(RPM) | 3000 |

| Rated Torque(NM) | 2 |

| Peak Torque(NM) | 6 |

| Voltage Constantv10r/min | 56 |

| Torque Coefficient(NM/A) | 0.8 |

| Rotor Inertia(Kg.m²) | 0.31*10 |

| Line-Line Resistance(Ω) | 3.6 |

| Line-Line Inductance(mH) | 8.32 |

| Machanical Time-Constant(Ms) | 2.3 |

| Encoder Resolution(PPR) | 2500 |

| Insulation Class | Class B |

| Safety Class | IP65 |

| The Operating of Evironmental Condition | Temperature:-20℃~+45℃ Humidity Below 90%RH(No drawing) |

| Weight(KG) | 4.5 |

FAQ

Q: Are you trading company or manufacturer?

A: We are professional manufacturer cnc system products. And we trade our products with our clients directly.

Q: Can you do OEM and ODM?

A: Yes, OEM and ODM are both acceptable. The material, color, style can customize, the basic quantity we will advise after we discuss.

Q: Can we use our own logo?

A: Yes, we can print your private logo according to your request.

If you have another question, pls feel free to contact us as below