1000 watt 130mm Frame ac servo motor and driver

1000 watt 130mm Frame ac servo motor and driver for film drive belts, large air compressors, pumping units, etc.

Application

CNC Machinery,printing equipment, packaging equipment, textile equipment, laser processing equipment, robotics, automated production lines, such as processing precision, processing efficiency and reliability, and other requirements of the relatively high equipment.

Features

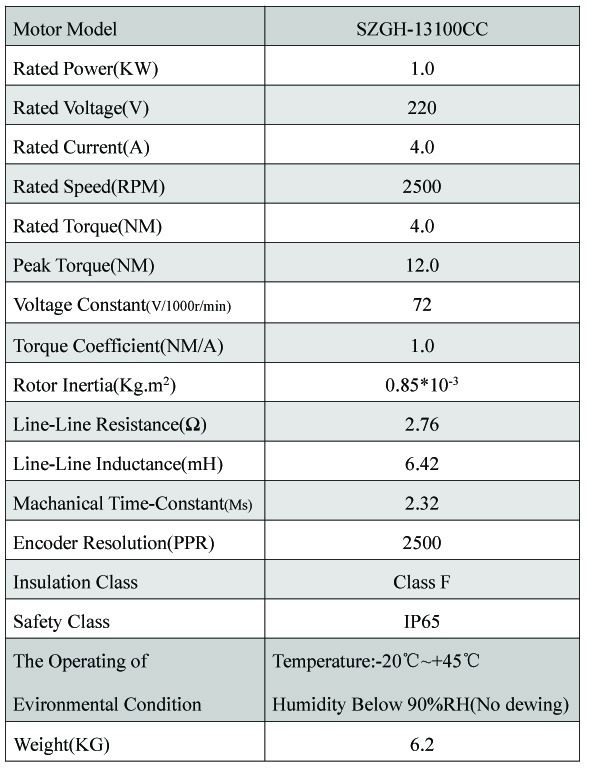

GH-13100CC is 1KW ,4NM and 2500RPM servo motor, it is low cost , and very general-purpose type. Imported feedback components, original imported low-noise motor.

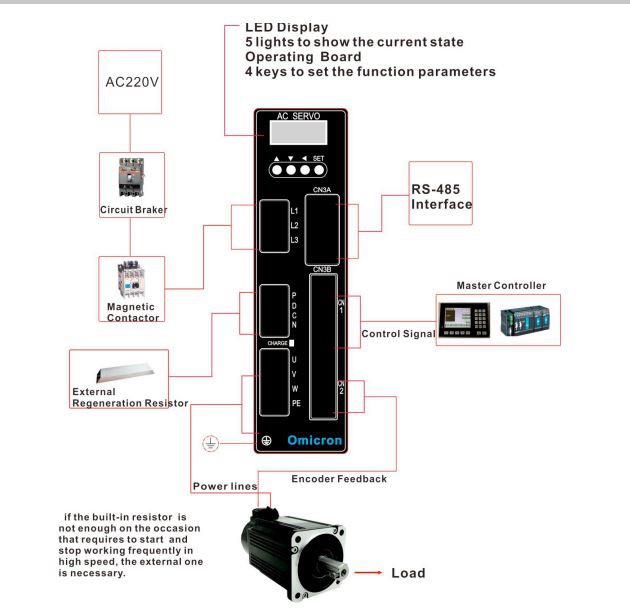

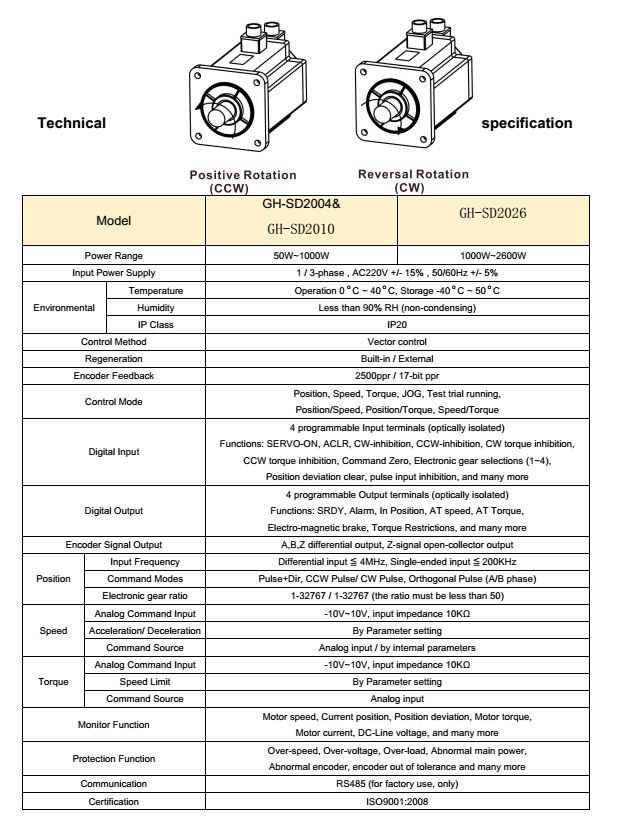

The are match servo driver, GH-SD2026,GH-201,GH-301, that matching for 1KW servo motor.

There is also one dual servo driver,GH-302,that can control two pcs of 1KW servo motors synchronously.

Related Model : GH-08100CC , GH-09100CC , GH-10100DC , GH-13100AC

FAQ:

1.Q. Can we print our own logo?

A. Yes,we offer OEM service.

2.Q. Do you provide sample?

A. Yes,we provide sample and the sample cost will be reback to you when confirm the order

3.Q. What's your products?

A. cnc controller ,servo system ,servo spindle system ,robot arm

4.Q:What’s the MOQ for your products?

A:Usually 1 carton .

5.Q:What’s the payment terms?

A:T.T with 30% downpayment,70%before shipment.or L/C at sight.

Paypal or West Union also accept.

6 .Q: May I know what’s the nearest airport from your company?in case I visit your company.

A: First shenzhen Airport,,then guangzhou or huizhou airport,welcome to visit us.