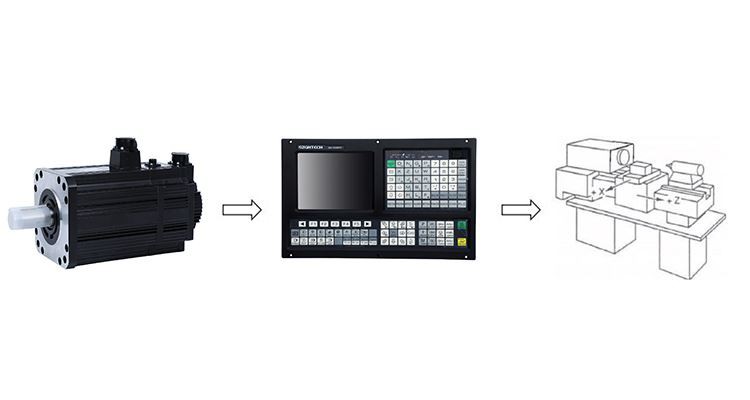

High speed and Torque Ac servo Motor 2.3KW 15Nm 1500RPM for Textile Machine Matched CNC Controller

This is a popular type servo motor in China. It is widely used in Packaging , Printing, Textile and so on. Because of the high quality for life long used, it has won high reputation in market by our customers. We do want to build futher relationship with you .

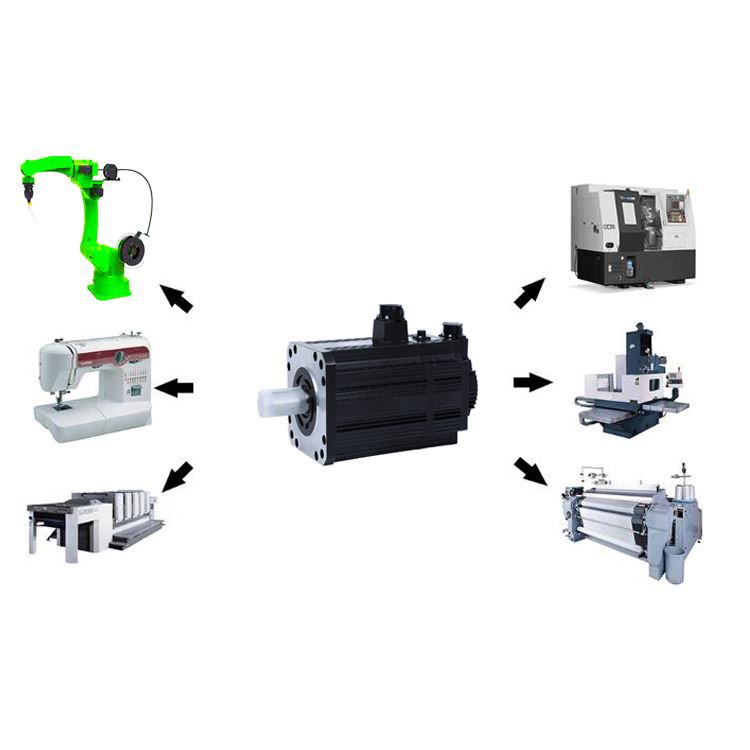

Application

CNC Machinery,printing equipment, packaging equipment, textile equipment, laser processing equipment, robotics, automated production lines, such as processing precision, processing efficiency and reliability, and other requirements of the relatively high equipment.

Features

GH-13100CC is 1KW ,4NM and 2500RPM servo motor, it is low cost , and very general-purpose type. Imported feedback components, original imported low-noise motor.

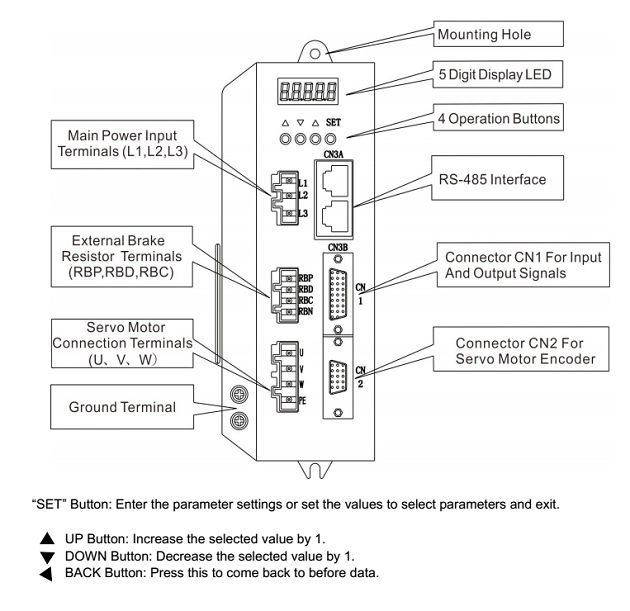

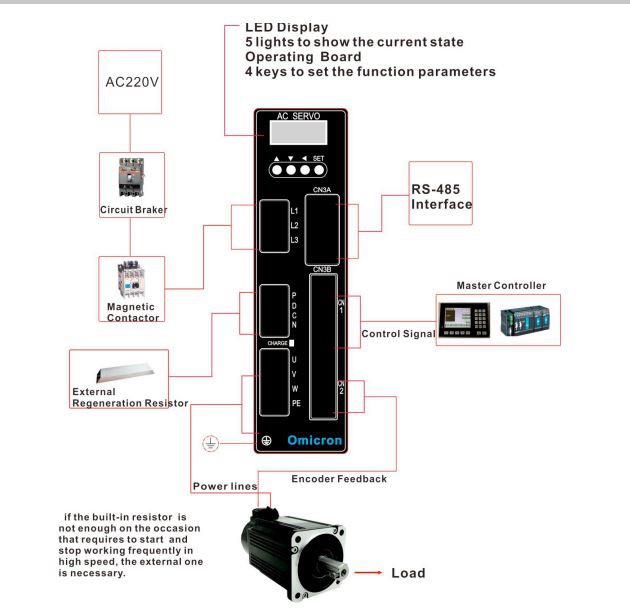

The are match servo driver, GH-SD2026,GH-201,GH-301, that matching for 1KW servo motor.

There is also one dual servo driver,GH-302,that can control two pcs of 1KW servo motors synchronously.

Related Model : GH-08100CC , GH-09100CC , GH-10100DC , GH-13100AC

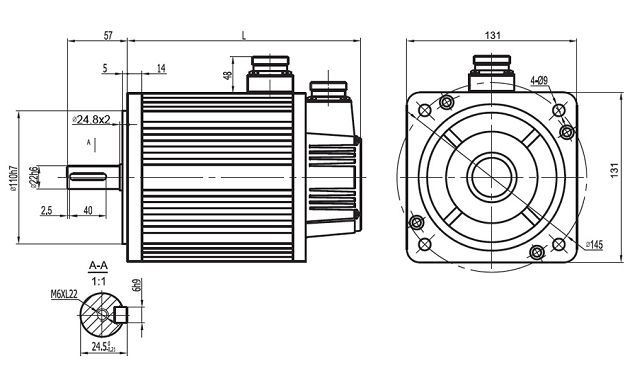

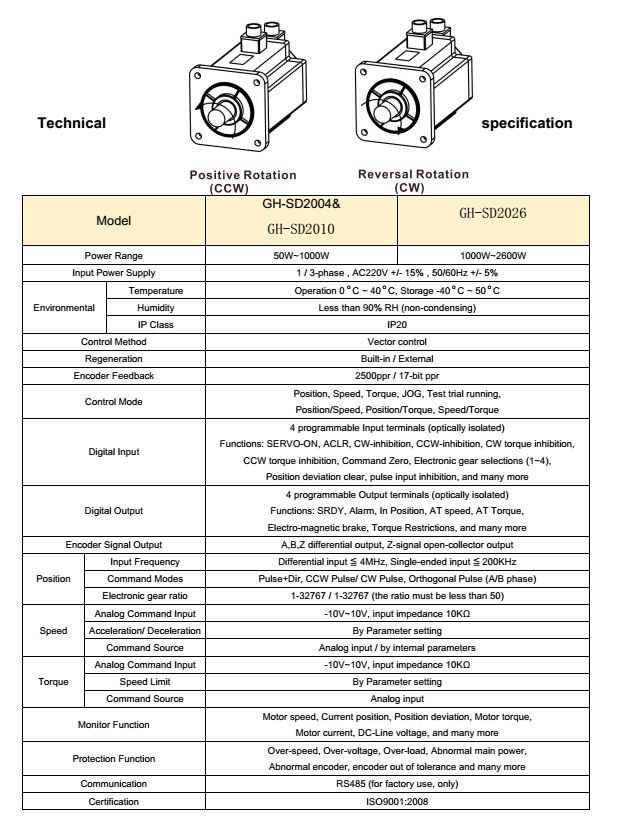

| Motor Model | SZGH-13230AC |

| Rated Power(KW) | 2.3 |

| Rated Voltage(V) | 220 |

| Rated Crrent(A) | 2.5 |

| Rated Speed(RPM) | 1500 |

| Rated Torque(NM) | 15 |

| Peak Torque(NM) | 30 |

| Voltage Constantv10r/min | 56 |

| Torque Coefficient(NM/A) | 1.58 |

| Rotor Inertia(Kg.m²) | 2.77*10 |

| Line-Line Resistance(Ω) | 1.1 |

| Line-Line Inductance(mH) | 4.45 |

| Machanical Time-Constant(Ms) | 4.05 |

| Encoder Resolution(PPR) | 2500 |

| Insulation Class | Class B |

| Safety Class | IP65 |

| The Operating of Evironmental Condition | Temperature:-20℃~+45℃ Humidity Below 90%RH(No drawing) |

| Weight(KG) | 12.6 |

Why choose us

We are one of the leading professional server and drive manufacturers in China.

We have been in this industry for nearly 10 years. More importantly, we have our

own factories and our product costs are competitive. At the same time, we attach

great importance to quality control. Each product will be carefully tested before

assembly. If you need any help during use, you can contact our technical department,

and we have a professional technical team to answer you.

FAQ

1. How can I place an order?

You can contact any of our sales person for an order. Please provide the details of

your requirements as clear as possible. So we can send you the offer at the first time.

For further discussion, it is better to contact us with Skype, TradeManger or QQ or WhatsApp or other instant ways, in case of any delays.

2. When can I get the price?

Usually we quote within 8 hours after we get your inqute