Single-Phase AC Servo Motor 1.8kw 6NM 3000rpm AC Servo Motor And Driver For CNC Controller

Features

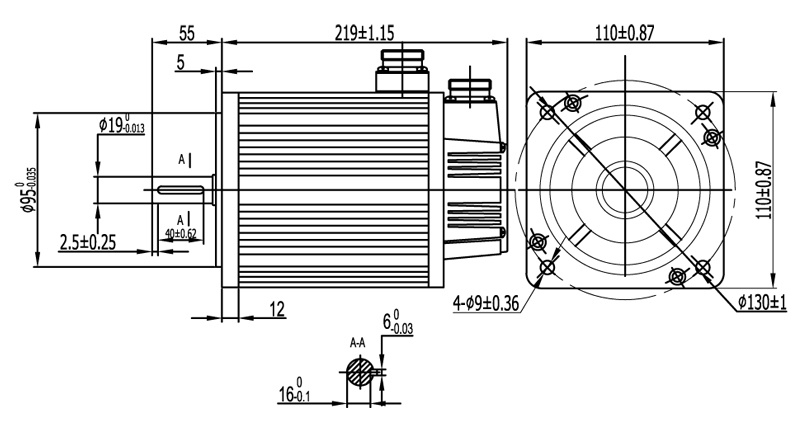

GH-11180DC is 1800W servo motor system,6.0NM,3000RPM. specailly design with bigger and beautiful contour, large load , long-term continuous working in rated working mode.

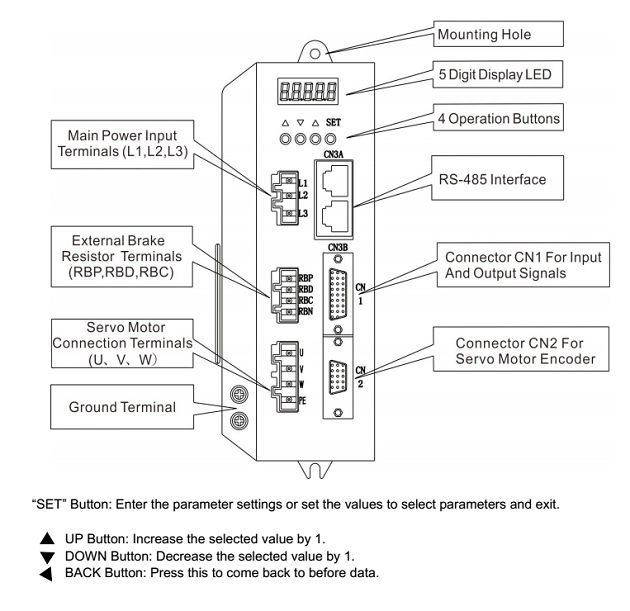

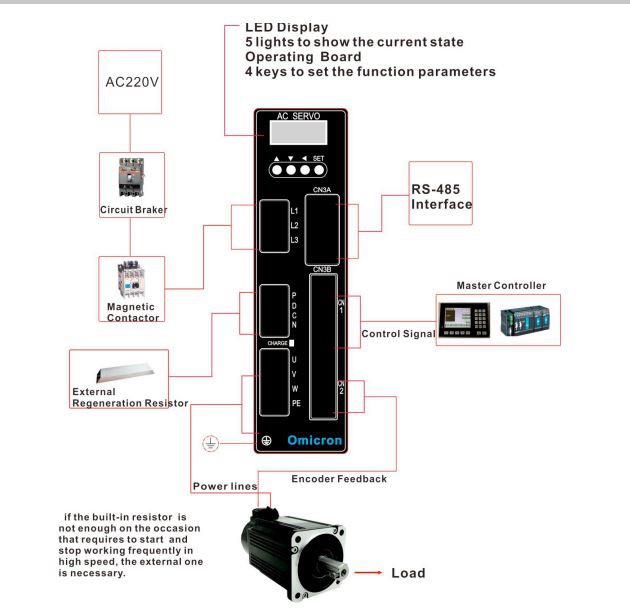

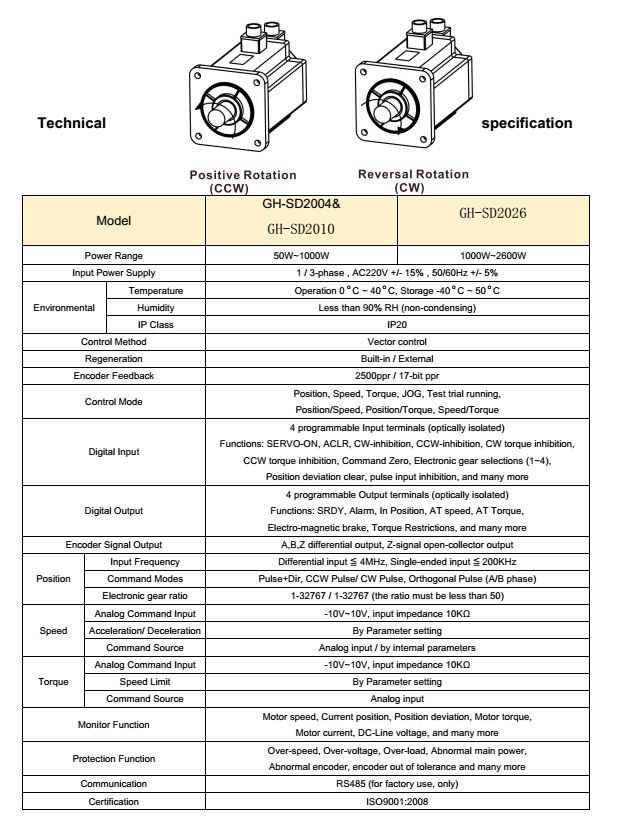

GH-SD2026 that matching for 1.8KW servo motor.

| Motor Model | SZGH-11180DC |

| Rated Power(KW) | 1.8 |

| Rated Voltage(V) | 220 |

| Rated Crrent(A) | 6.0 |

| Rated Speed(RPM) | 3000 |

| Rated Torque(NM) | 6 |

| Peak Torque(NM) | 18 |

| Voltage Constantv10r/min | 60 |

| Torque Coefficient(NM/A) | 1 |

| Rotor Inertia(Kg.m²) | 0.76*10 |

| Line-Line Resistance(Ω) | 0.81 |

| Line-Line Inductance(mH) | 2.59 |

| Machanical Time-Constant(Ms) | 3.2 |

| Encoder Resolution(PPR) | 2500 |

| Insulation Class | Class F |

| Safety Class | IP65 |

| The Operating of Evironmental Condition | Temperature:-20℃~+45℃ Humidity Below 90%RH(No drawing) |

| Weight(KG) | 7.9 |

Application

Servo motors are mainly used in high speed machining centers and CNC machine tools. The motor feed system can directly provide thrust to the load, without any intermediate mechanical transmission structure. Using it can greatly improve the speed, accuracy and efficiency of the feed drive of machine tools. Compared with the traditional drive mode, servo motor feed system has many advantages

Servo motor advantages:

1.Operate Steadily 2.High Precision 3.Big Power Range(50W-11KW)

4. Strong Overload Resistance 5.High Speed and Excellent Performance

FAQ

Q: May I know what’s the nearest airport from your company?

A: First shenzhen Airport,,then guangzhou or huizhou airport,welcome to visit us.

Q: When can I get the quotation?

A: We usually quote within 3 hours after we get your inquiry. If you are very urgent to get the price, please tell us so that we will regard your inquiry priority.

Q: What about the lead time for mass production?

A: 6-8 working days for mass production.It depends on your quantity,and we will try our best to meet your needs.

If you have any other question about our 1 .8kw 6NM AC Servo Motor And Driver , pls feel free to contact us as below