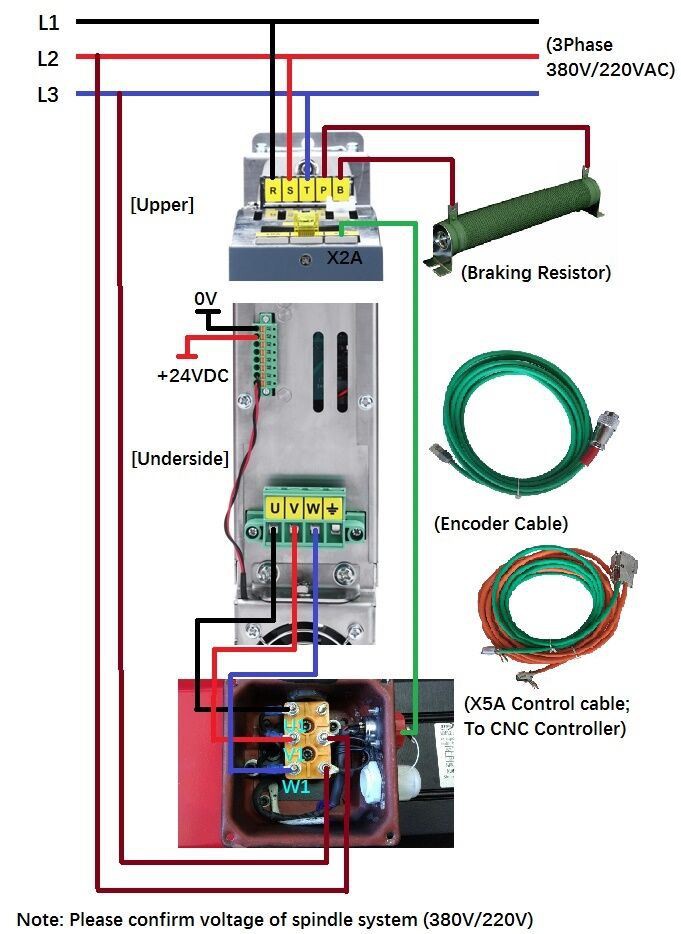

Input Power | Rated Voltage/frequency | Three-phase 380V/480V;50Hz/60Hz |

Allowable Voltage range | +10%~-15% | |

Allowable Frequency Fluctuation | ± 5% | |

Control Features | Control Mode | PWM Vector Control |

Speed Adjustment Range | 0.01~500Hz | |

Speed Stabilization Precision | ± 0.1% | |

Acceleration/Deceleration time | 0.05~3000Hz/s | |

Torque Control | 200% Rated torque output;Torque precision ±5% | |

Position Control Precision | ±1 Pulse | |

Braking Mode | Powered Braking | |

Overload Capacity | Twice Overload | |

I/Os | Digital Input | 10 points , NPN or PNP(Optional) |

Digital Output | 6 points , NPN | |

Relay Output | 2pcs ,DC30V/1A Or AC250V/1A | |

Analog Input | 2 inputs, A0:±10V; A1: 0~±10V Or 4~20mA | |

External Pulse Input | 1 type ,ABZ phase pulse ,Pulse+Direction Or | |

Motor Encoder Input | 1 type,RS422 TTL , Rotatry Connector(Optional) | |

Motor Encoder Output | 1 pcs,RS42TTL ,Output Frequency Range: | |

Protection Function | Over-Voltage Protection,Low-Voltage Protection,Over-Current Protection,Over-Heat | |

WorkingEnvironment | Operating Site | The product shall be mounted verticlly in the |

Humidity | 5~90%, not allow condensing | |

Altitude | 0~3000Meters,derated above 1000m, the | |

Vibration | Under 20Hz:1G; 20~50Hz: 0.2G | |

Independent Quasi Stop: Positioning with High Precision(0.03。)

Rigid Tapping: Max speed of tapping is 3000RPM ,Min of dental work is M3 ;

Function of C-Axis: Indexing Accuracy: +/-1 Pulse ; Turning/Milling: 0.01rpm ;

Cutting in Low Speed: Overload(3 times holding torque),ensure stablity of cutting,applied in casting process;

High-Speed Precision Machining: Constant power output over 4000RPM,stable ratoting speed,ensure finish;

Strong Applicability: Match for CNC System , PLC etc.

Powerful Development : Custome Manufacturing .

FAQ

Q: Which shipping way can you provide?

A: We can provide shipping by sea, by air and by express.

Q: What’s your after-sale service?

A: Our quality warranty period is one year. Any quality problem will be solved to customer satisfactions.