▶ Features:

Powerful Expansion Capability(Optional)

Spindle driver can be configured with many kinds of expansion modules,such as Digital terminal expansion modules, Analog terminal expansion modules, Encoder feedback divider output, RS485 ModBus RTU,CANopen, GSM/GPRS modules,digital display module, double position loop module interfaces.

And also it can also be customized manufactured according to the user's specific applications, conveniently connected to CNC controller, HMI, PLC and other control devices.

Safe & Reliable

Products comply with international standard,improved with CE certification. Setup mulitiple protection circuit,the comprehensive protection of safety equipment.

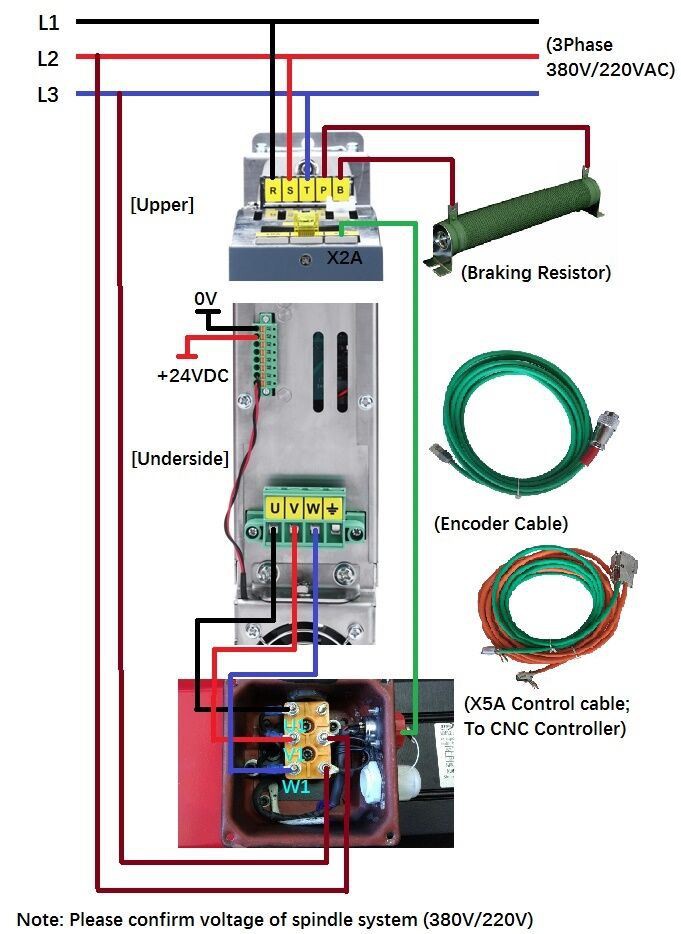

Input Power | Rated Voltage/frequency | Three-phase 380V/480V;50Hz/60Hz |

Allowable Voltage range | +10%~-15% | |

Allowable Frequency Fluctuation | ± 5% | |

Control Features | Control Mode | PWM Vector Control |

Speed Adjustment Range | 0.01~500Hz | |

Speed Stabilization Precision | ± 0.1% | |

Acceleration/Deceleration time | 0.05~3000Hz/s | |

Torque Control | 200% Rated torque output;Torque precision ±5% | |

Position Control Precision | ±1 Pulse | |

Braking Mode | Powered Braking | |

Overload Capacity | Twice Overload | |

I/Os | Digital Input | 10 points , NPN or PNP(Optional) |

Digital Output | 6 points , NPN | |

Relay Output | 2pcs ,DC30V/1A Or AC250V/1A | |

Analog Input | 2 inputs, A0:±10V; A1: 0~±10V Or 4~20mA | |

External Pulse Input | 1 type ,ABZ phase pulse ,Pulse+Direction Or | |

Motor Encoder Input | 1 type,RS422 TTL , Rotatry Connector(Optional) | |

Motor Encoder Output | 1 pcs,RS42TTL ,Output Frequency Range: | |

Protection Function | Over-Voltage Protection,Low-Voltage Protection,Over-Current Protection,Over-Heat | |

WorkingEnvironment | Operating Site | The product shall be mounted verticlly in the |

Ambient Temperature | -10℃ ~ +45℃ | |

Humidity | 5~90%, not allow condensing | |

Altitude | 0~3000Meters,derated above 1000m, the | |

Vibration | Under 20Hz:1G; 20~50Hz: 0.2G |

FAQ

Q: How long is your delivery time?

A: The general delivery time is 4-6 days after receiving your order confirmation. , if we have the goods in stock, it will only take 1-2 days.

Q: Do you provide sample ? Is it free?

A: If the sample is low value, we will provide the free sample with freight collect. But for some high value samples, we need to collect the sample charge.

Q: What is your term of payment?

A: 50% down payment before producing and 50% balance payment before shipping.

Q: Which payment form you can accept?

A: T/T, Western Union, PayPal etc. We accept any convenient and swift payment term.