Factory Direct as Gsk 2 Axis Cnc Lathe Controller Box for Auto Tool Setter Probe two axis cnc Turning machine cnc controller

Number of control axes | 2 axes (X, Z) |

Minimum programming | 0.001mm |

Maximum programming | ± 99999.999mm |

Top speed | 30m / min |

Feed speed | 0.001-15m / min |

Manual continuous | One axis or simultaneous multi-axis |

Interpolation method | Straight line, arc, thread interpolation |

Tool offset | Length compensation, nose radius C compensation |

Spindle functions | Gear, dual analog control, rigid tapping |

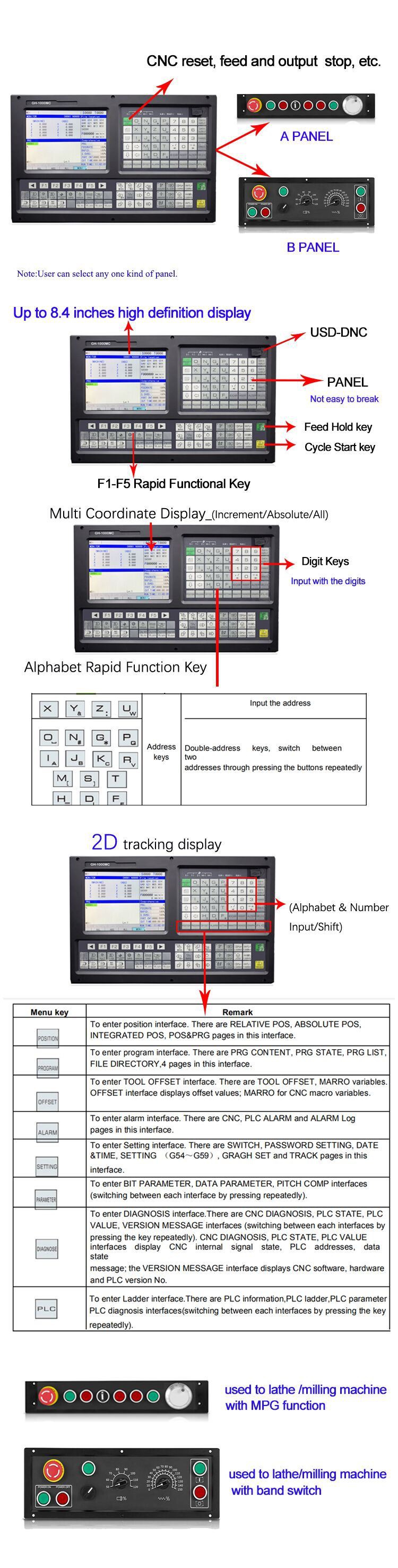

Handwheel functions | Panel type, plug-in hand-held |

Screen saver function | Screen saver function |

Communication function | RS232, U disk interface |

Compensation function | Knife compensation, between compensation, screw compensation, radius compensation |

Program editing | Male / English, relative / absolute programming |

Limit function | Software limit, hardware limit |

Pre-reading function | Short line preprocessing 10,000 lines |

Password protection | Multi-level password protection |

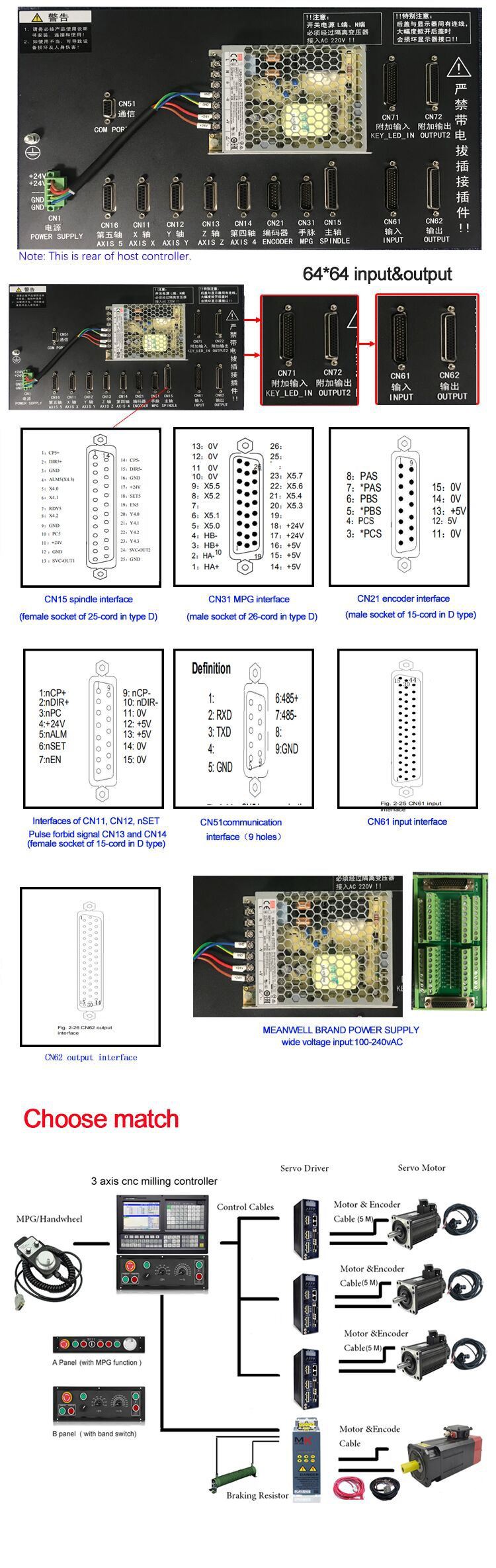

Input and output | I / O point 24X24 |

PLC programming | The user is free to design PLC function |

Acceleration and deceleration control | Linear acceleration and deceleration, the number of additions and subtractions |

Encoder lines | Any setting |

User macro program | Yes |

Electronic gear functions | Yes |

Number of control axes | 2axes (X, Y) |

Minimum programming | 0.001mm |

Application: CNC Lathe & Turning Machinery and specially automatic equipment

Support turning and milling compound machining, support high-speed and high-precision small line segment machining, support multiple sets of G code instructions, support dual-channel control, support spindle synchronous control, support feed shaft synchronous control, support inclined shaft control, integrated truss/fetching and discharging arm control function

The system software version can be flexibly configured as the single-channel high-speed and high-precision standard version, the dual-channel turning/milling standard version and the dual-channel truss special version, which can be adapted to a variety of machine tool layouts to meet the functional requirements of complex applications.

1) Tool length compensation

2) Tool point radius compensation (C type)

Precision compensation:

1) Thread pitch error compenstation: Compensation points, compensation interval, compensate original position can be set.

2) Backlash compensation: can set reverse interval to interpolation machine tool by fixed frequency or lifting speed mode.

PLC functions:

1) Two levels PLC programming, operation speed is 1.5μs/ step basic instruction; 4700 steps mostly, the cycle of the first level programming is 8ms.2) Support PLC warning and PLC alarm.

Related products:

2)Axis servo motor &driver

3)Spindle Servo Motor&driver

4)Rotary table

FAQ

Q: Which payment form you can accept?

A: T/T, Western Union, PayPal etc. We accept any convenient and swift payment term.

Q: Which certificate do you have?

A: CE and ER

Q: About CNC lathe controller do you have the test and audit service?

A: Yes, we can assist to get the designated test report for product and the designated factory audit report.

Our Service

1.More Professional service in cnc system total products exporting field

2.Better manufacture ability

3.Various payment term to choose:T/T,Western Union,L/C,Paypal

4.High quality/Safe material/Competitive price

5.Small order available

6.Quickly response

7.More safe and fast transport

8.OEM design for all customers

If you have another question, pls feel free to contact us as below