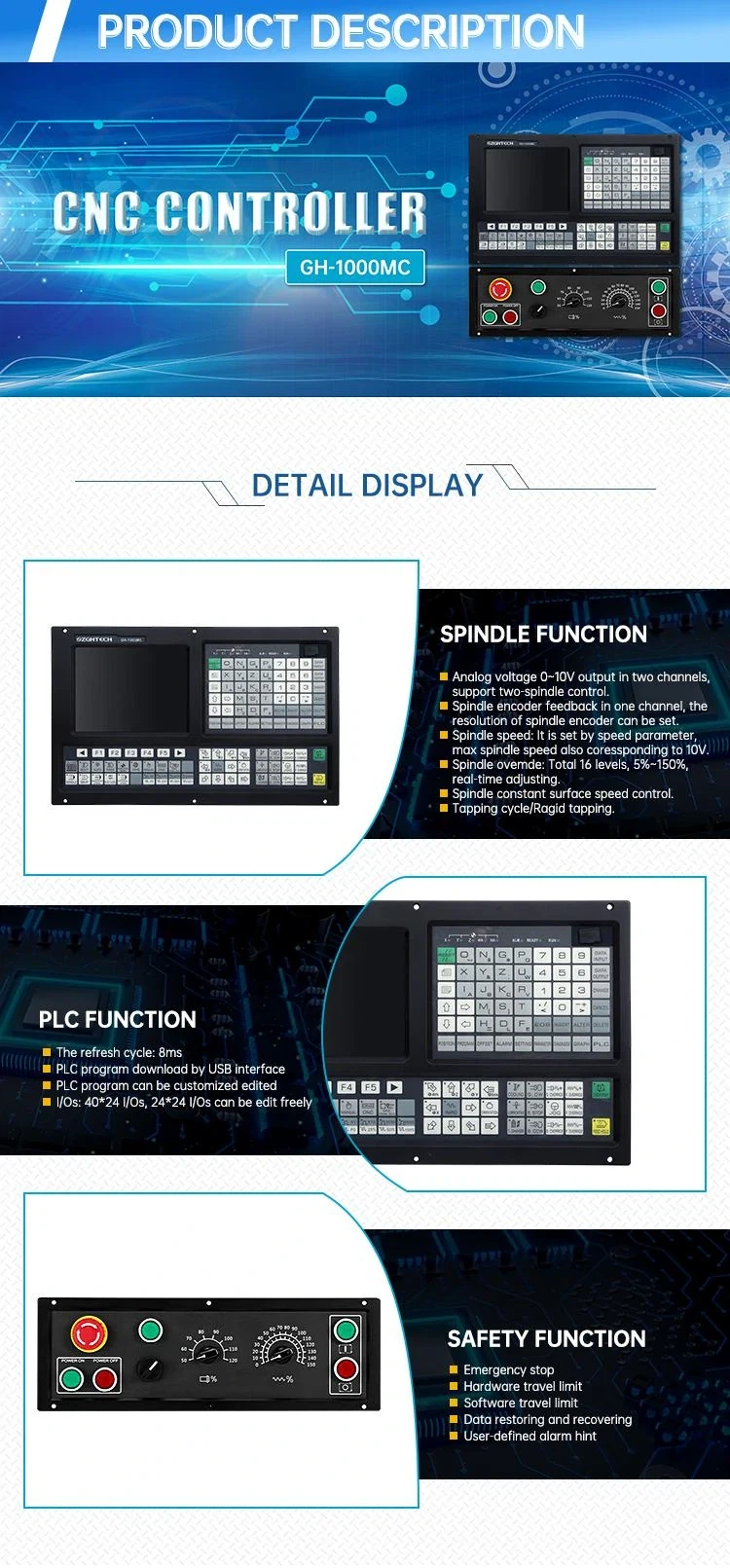

High Precision router kit NEW GH-1000MC cnc+ controller for milling machine similar cnc 3 axis controller for plate drilling machine

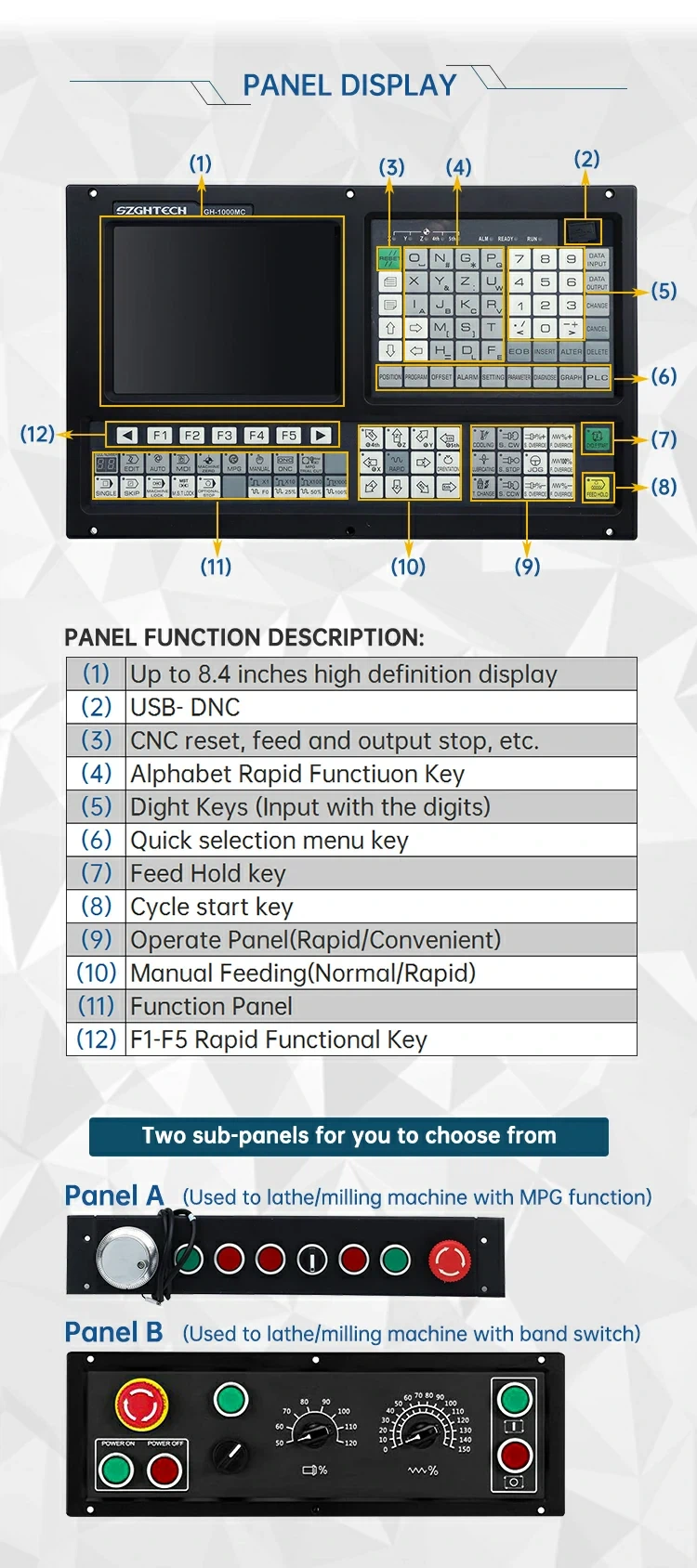

| Number of control axes | 3 axes (X, Y, Z) |

| Minimum programming | 0.001mm |

| Maximum programming | ± 99999.999mm |

| Top speed | 30m / min |

| Feed speed | 0.001-15m / min |

| Manual continuous | One axis or simultaneous multi-axis |

| Screen saver function | Screen saver function |

| Communication function | RS232, U disk interface |

| Compensation function | Knife compensation, between compensation, screw compensation, radius compensation |

| Program editing | Male / English, relative / absolute programming |

| Pre-reading function | Short line preprocessing 10,000 lines |

| Acceleration and deceleration control | Linear acceleration and deceleration, the number of additions and subtractions |

| Electronic gear functions | Yes |

1) Max speed is 60m/min, feeding speed is 24m/min,0.1um control precision

2) Adapted servo spindle can realize spindle continous position,rigid tapping,rigid screw processing

3) Support ATC(ATC function is Umbrella Type/Arm Type/Linear Type/Servo Type/Special Tool Magazine)

4) Support Macro function

5) Support PLC function(PLC program download by USB interface,PLC program can be customized edited and edit freely)

Application : CNC Milling & Drilling Machinery and specially automatic equipment

FAQ

1. Can you do OEM product?

Yes,we are able to do OEM.The material, color, style can customize, the basic quantity we will advise after we discuss.

2. How about the further development?

All open PLC and macro which could be developed freely.

3. Can you custom print with our logo?

Yes, we can print your private logo according to your request.

4. How many different types of products your company manufactures?

Now we have more than 300 products. We have a strong advantage of OEM, just give us the actual products or your idea that you want, we will manufacture for you.

5. What services can we provide?

1).Accepted Delivery Terms: FOB, CFR, CIF, EXW, FAS, CIP, FCA, DDP, DDU, DAF;

2).Accepted Payment Currency: USD, EUR, CAD, HKD, CNY;

3).Accepted Payment Type: T/T, L/C, D/P D/A, Credit Card, PayPal, Western Union, Cash,Escrow; 4).Language Spoken: English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Italian and so on.

6. How long is your delivery time?

The general delivery time is 4-6 days after receiving your order confirmation. , if we have the goods in stock, it will only take 1-2 days.

7. Do you provide sample? Is it free?

If the sample is low value, we will provide the free sample with freight collect. But for some high value samples, we need to collect the sample charge.

If you have another question, pls feel free to contact us as below.