Mach3 CNC Milling Controller for plate drilling machine Video technical support

1) 3-5 Axis Fully English Type CNC lathe controller

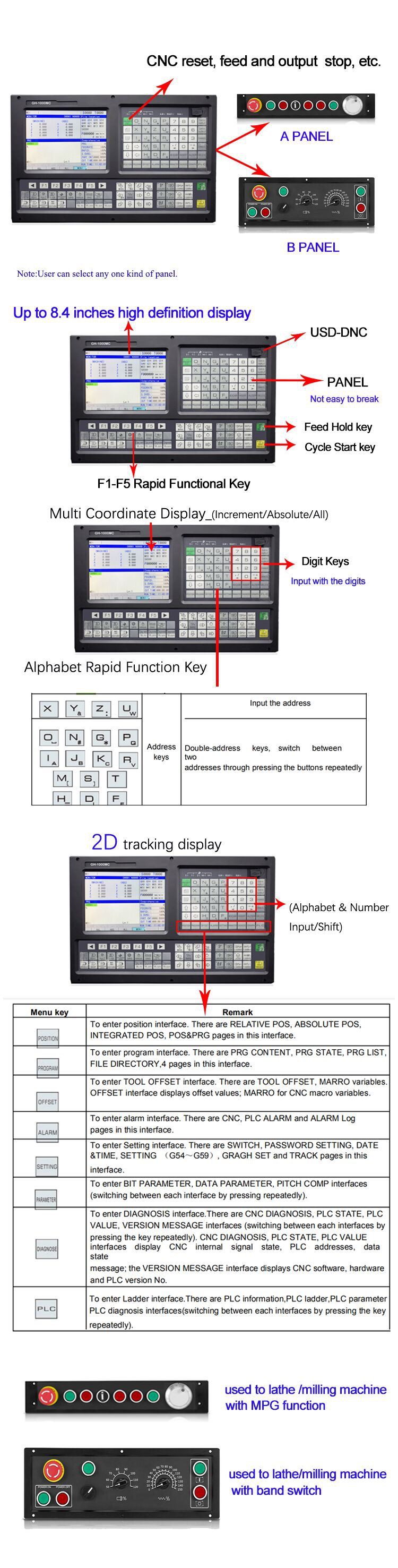

2) 800x600 8.4 inch real color LCD displayer

3) Electric Turret & Binary code turret,Max: 99 pcs tools

4) Support ATC , Macro function and PLC function

5) Max speed is 60m/min, feeding speed is 24m/min,0.1um control precision

6) Adapted servo spindle can realize spindle continous position,rigid tapping,rigid screw processing

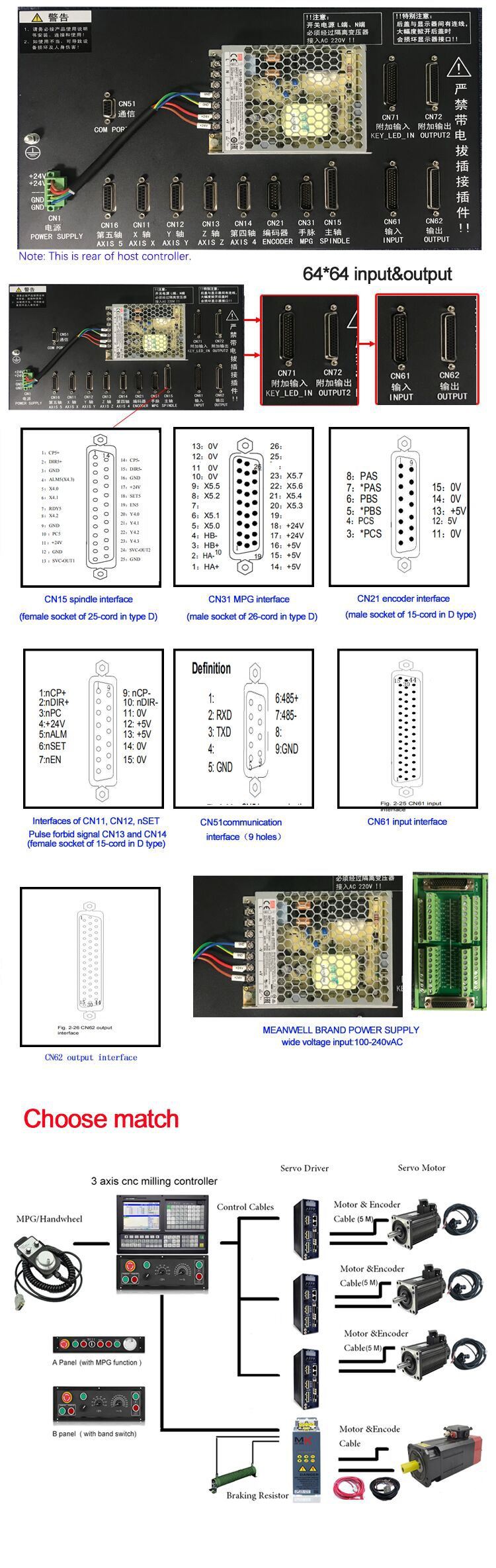

7) High anti-jamming switch power(100V-240VAC 50Hz/60Hz -> 24VDC)

Spindle axis functions:

1) Two channels 0V ~ 10V analog voltage output, support double spindle control

2) Spindle encoder: encoder lines can be set (100 p/r ~ 5000p/r)

3) Encoder and spindle’s transmission ratio: (1 ~ 255):(1 ~ 255)

4) Spindle ration: 50% ~ 120% eight stages real-time tunning in total

5) Spindle axis constant line speed control

6) Tapping circle, rigid tapping

Tool functions:

1)Tool length compensation

2)Tool point radius compensation (C type)

Precision compensation:

1)Thread pitch error compenstation: Compensation points, compensation interval, compensate original position can be set.

2)Backlash compensation: can set reverse interval to interpolation machine tool by fixed frequency or lifting speed mode.

PLC functions:

1)Two levels PLC programming, operation speed is 1.5μs/ step basic instruction; 4700 steps mostly, the cycle of the first level programming is 8ms.

2)Support PLC warning and PLC alarm.

3)Support multiply PLC programming (mostly 20), the current PLC programming can be chosen.

4)45 kinds of commands (10 kinds of basic commands, 35 kinds of function commands)

3)Support multiply PLC programming (mostly 20), the current PLC programming can be chosen.

4)45 kinds of commands (10 kinds of basic commands, 35 kinds of function commands)

Application : CNC Lathe & Turning Machinery and specially automatic equipment

FAQ

Q: Are you trading company or manufacturer?

A: We are professional manufacturer cnc system products. And we trade our products with our clients directly.

Q: Can you do OEM and ODM?

A: Yes, OEM and ODM are both acceptable. The material, color, style can customize, the basic quantity we will advise after we discuss.

Q: Can we use our own logo?

A: Yes, we can print your private logo according to your request.

Q: How many different types of products your company manufactures?

A: Now we have more than 300 products. We have a strong advantage of OEM, just give us the actual products or your idea that you want, we will manufacture for you.

Q: When can I get the price?

A: Usually we quote within 8 hours after we get your inquiry.

Q: What’s your MOQ?

A: If we have the products in stock, it will be no MOQ. If we need to produce, we can discuss the MOQ according to the customer’s exact situation.

Q: How long is your delivery time?

A: The general delivery time is 4-6 days after receiving your order confirmation. , if we have the goods in stock, it will only take 1-2 days.

Q: Do you provide sample? Is it free?

A: If the sample is low value, we will provide the free sample with freight collect. But for some high value samples, we need to collect the sample charge.

Our Service

1.More Professional service in cnc system total products exporting field

2.Better manufacture ability

3.Various payment term to choose:T/T,Western Union,L/C,Paypal

4.High quality/Safe material/Competitive price

5.Small order available

6.Quickly response

7.More safe and fast transport

8.OEM design for all customers

If you have another question, pls feel free to contact us as below.