| Number of control axes | 3 axes |

| Minimum programming | 0.001mm |

| Maximum programming | ± 99999.999mm |

| Top speed | 30m / min |

| Feed speed | 0.001-15m / min |

| Manual continuous | One axis or simultaneous multi-axis |

| Screen saver function | Screen saver function |

| Program editing | Male / English, relative / absolute programming |

| Pre-reading function | Short line preprocessing 10,000 lines |

| Compensation function | Knife compensation, between compensation, screw compensation, radius compensation |

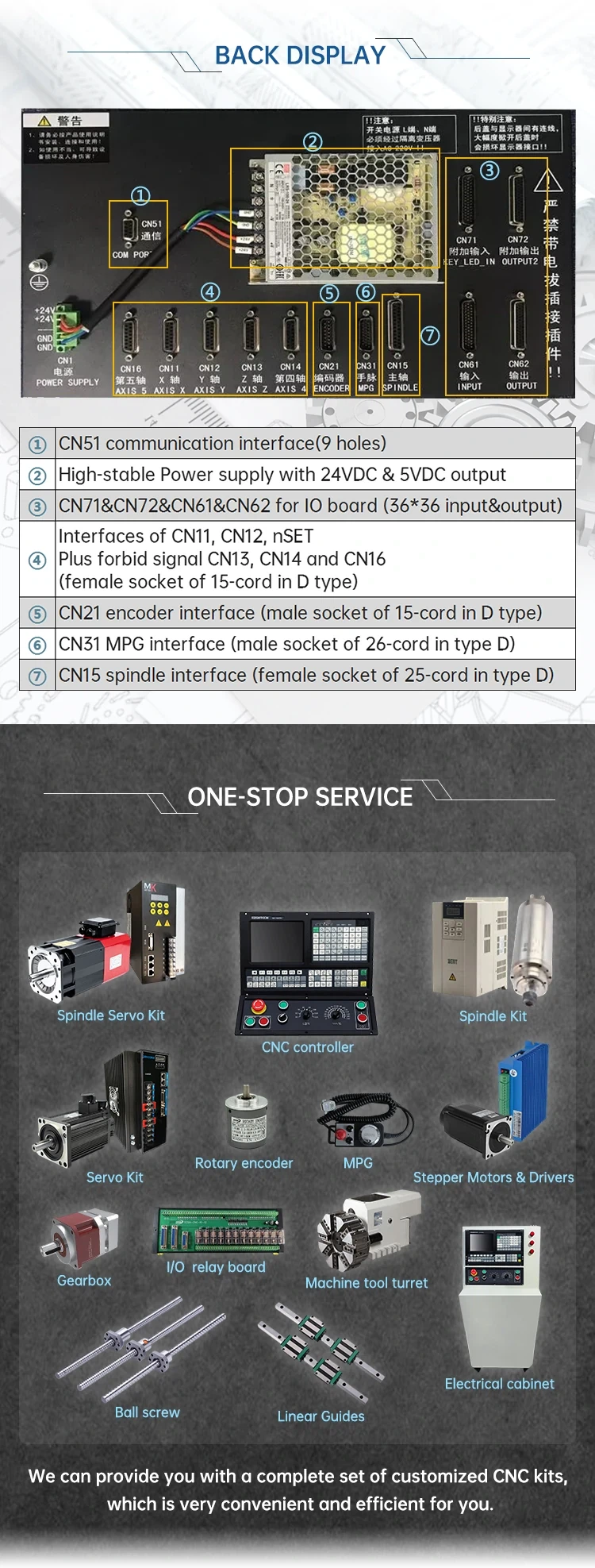

| Communication function | RS232, U disk interface |

| Program editing | Male / English, relative / absolute programming |

Tool functions: | 1)Tool length compensation |

| Password protection | Multi-level password protection |

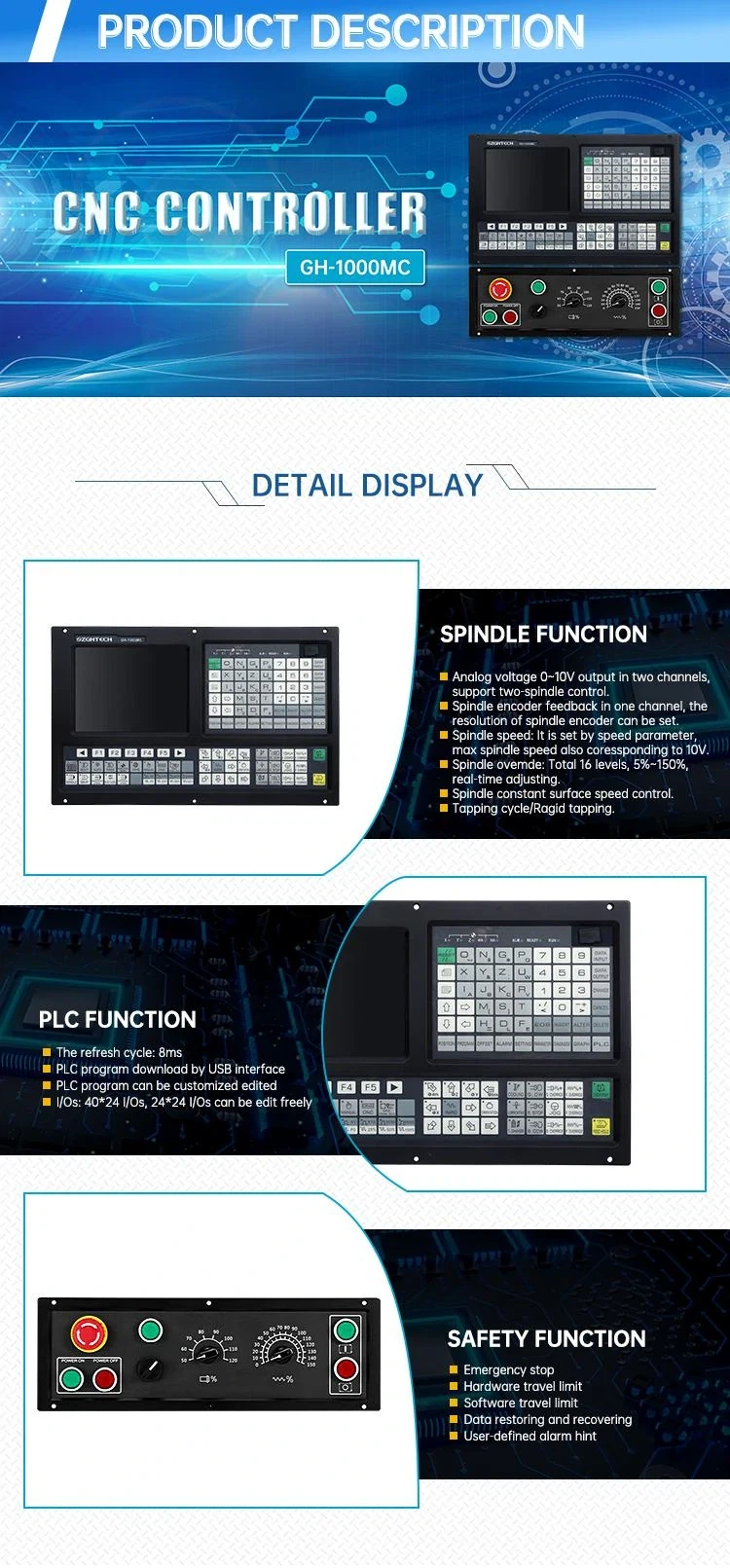

Features:

1. The minimum control accuracy is 0.1 μm, and the maximum moving speed is 60m/min;

2. It can realize spindle orientation, rigid tapping, cylindrical interpolation and indexing table control;

3. Built-in PLC, ladder diagram online display, real-time monitoring, support for I/O unit expansion, suitable for disc type and bucket hat type tool magazines;

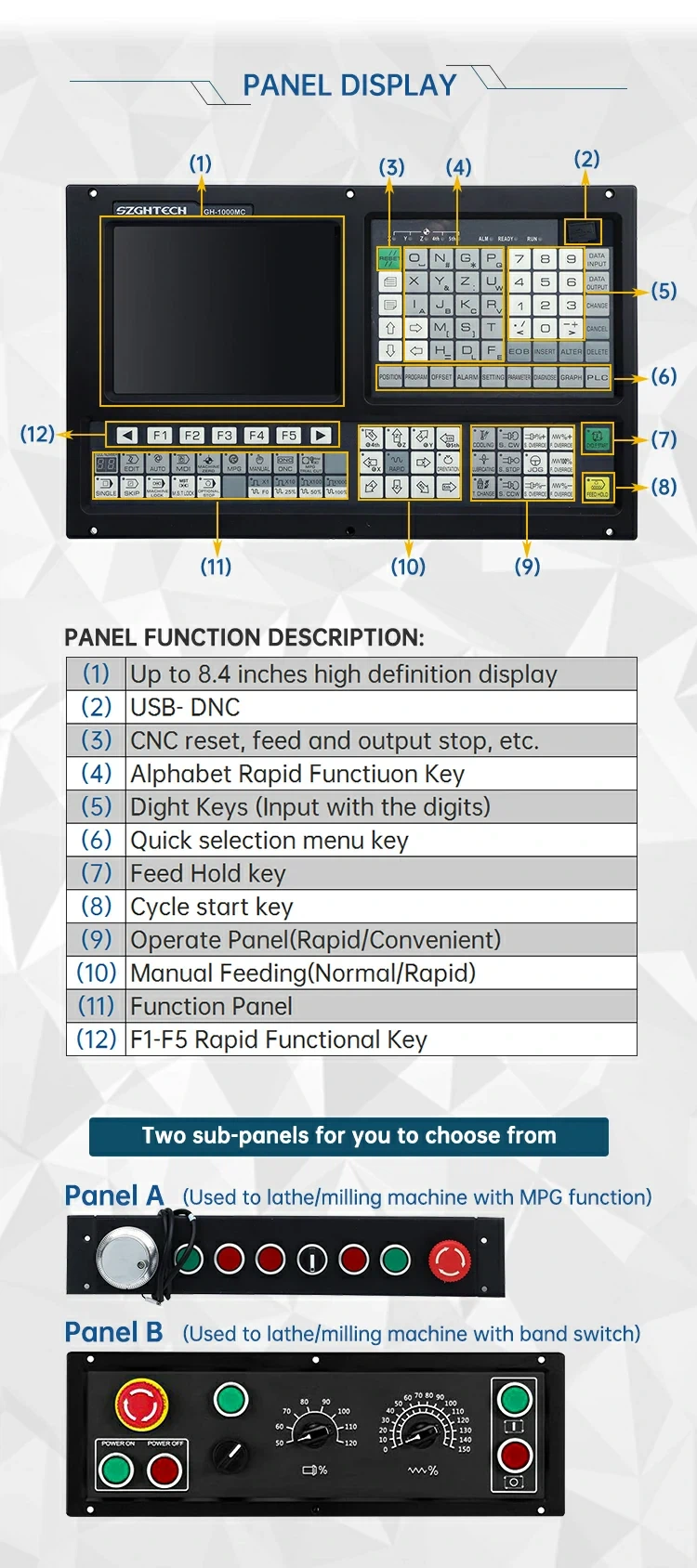

4. 8.4 o'clock true color LCD, support Chinese, English, Russian and other multi-language display.

Multiple function:

It can realize the drilling/boring,roughing of roungroove / rectanglegroove ,finishing of full circle /rectangle, continous drilling of straight line /rectangle /arc etc.

FAQ

Q1. Is it acceptable to print my logo on the product?

A: Yes. Please inform us formally before our product and confirm the design firstly based on our sample.

Q2: Do you offer guarantee for the products?

A: Yes, we offer one-year warranty for our products.

Q3: How to deal with the flaw?

A: Our products are produced in strict quality control system and the percent of pass is often maintained over 99.8%

Q4. How do you ship the goods and how long does it take to arrive?

A: We often ship by DHL, UPS, FedEx or TNT. It usually takes 3-5 days to arrive. Airline and sea shipping is also optional.

If you have any questions, pls feel free to contact us. We'll be sure to get back to you within an hour on a business day.