No. of Linkage Axis | 2-4 axes |

Highest Speed | 24m/min |

Programming Unit | 0.001mm |

I/O Control | Input (optoelectronic isolation)*13, output (relay output)*8 |

Store Space | 32-64M and it supports USB |

Programming | ISO-G code and manual programming |

Display | 7" color LCD |

Dimension | 300*204*93mm |

Working Temperature | 0℃ ~ 55℃ |

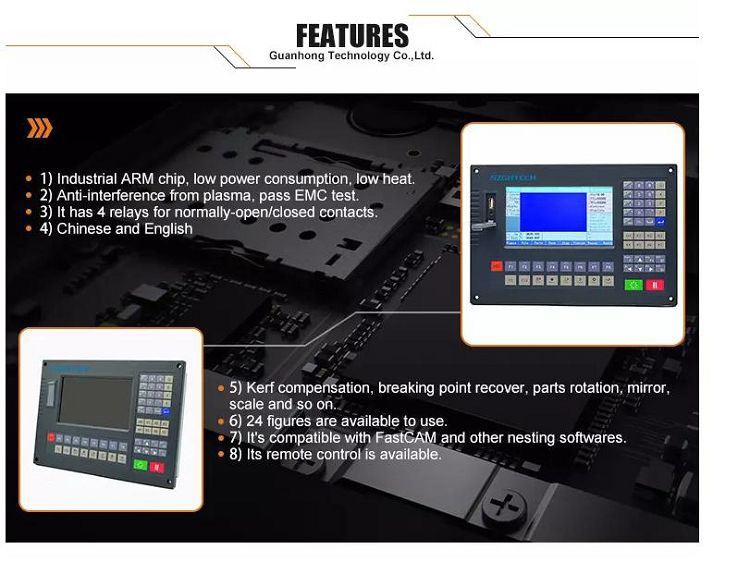

2012AH flame/plasma cutting controller, specially for economical cutting machines, such as portable type and other small equipments.

7" color LCD, the best performance, easy operation.

Technical Parameters

★ No. of Linkage Axis: 2-4 axes

★ Highest Speed: 24m/min

★ Programming Unit: 0.001mm

★ I/O Control: input (optoelectronic isolation)*13, output (relay output)*8

★ Store Space: 32-64M and it supports USB

★ Programming: ISO-G code and manual programming

★ Display: 7" color LCD

★ Dimension: 300*204*93mm

★ Working Temperature: 0℃ ~ 55℃

★ SH-2012AH flame/plasma cutting controller

FAQ

Q: Do you support customized manufacturing?

A: Yes,we can customized manufacturing according to customer's requirment. We support to OEM your own company display interface and logo.

Q: How long is your delivery time?

A: Generally it is 3-5 days if the goods are in stock. or it is 5-10 days if the goods are not in stock, it is according to quantity.10-20 days if customized manufacturing.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample with sample price.

Q: What is your terms of payment ?

A: Payment<=2000USD, 100% in advance. Payment>=1000USD, 70% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us as below