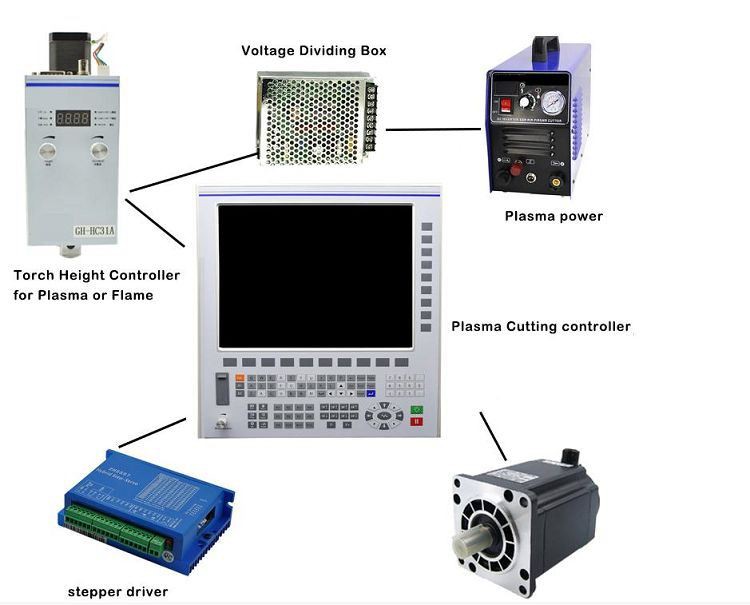

The GH-HC31 height controller for flame/plasma cutting torch is high performance and easy to use, automatic control module for cutting torch height with the integration of mechanical increase and electric control specially designed for portable flame and plasma cutting machine.

CNC Plasma controller Torch Height Controller 220V Automatic Arc and Cap Voltage with English Manual For CNC Flame Plasma Cutting Machine

Rade name | Flame / plasma cutting torch height controller |

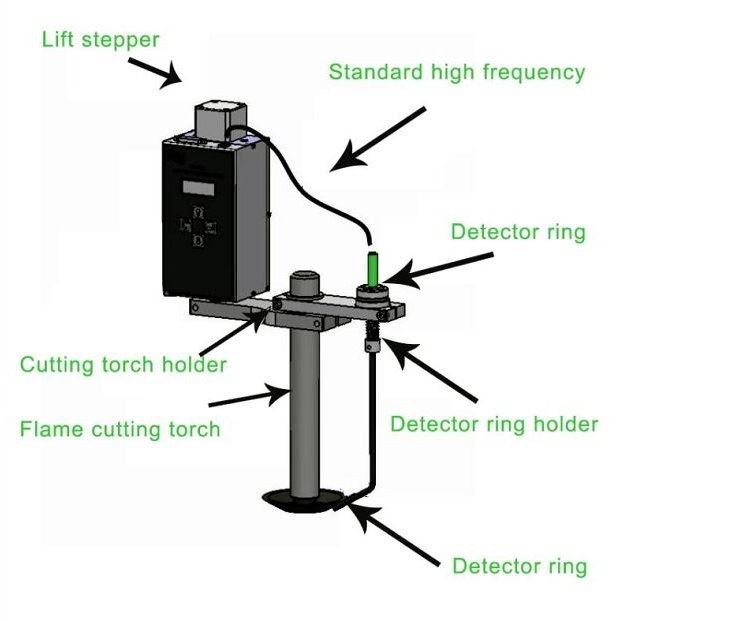

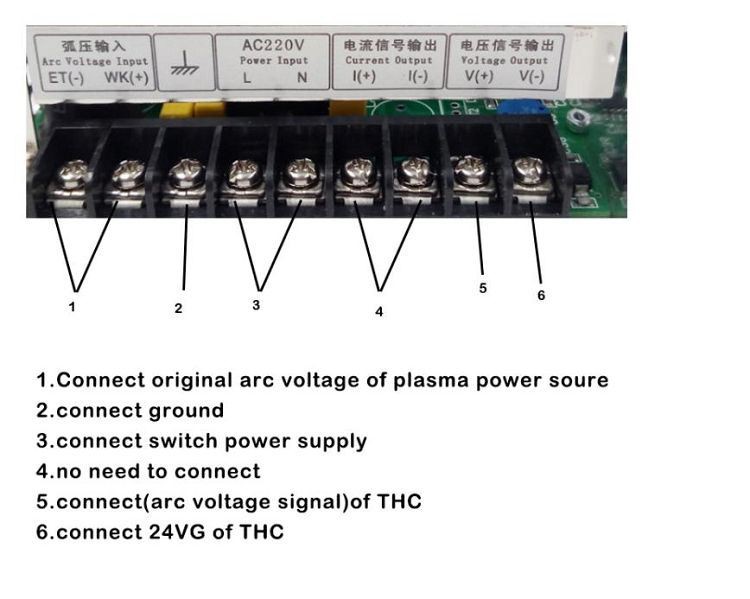

Power Requirements | DC 24V ± 2 V 220V 3 A |

Communication interface | RS232 |

Manual adjustment range | 0 ~ 100 mm |

Automatic increase of control range | 3 ~ 30 mm |

Automatic increase of control | 3000 mm / min (30 ° slope) |

Control precision | ±0.5 mm |

Dimensions of box body | (155 × 87 × 71) mm |

Operating temperature | -10 ~ 50 degree centigrade |

Detection system | capacitance-type detector, arc voltage height detector |

Manual adjustment range | 0-100mm |

1 | Stepper motor instead of the traditional DC motor |

2 | The height of cutting nozzle is displayed directly in the mode of |

3 | Integration of mechanical lifting device and height controller |

4 | All Digital Technology |

5 | Simple and convenient linearization calibration |

6 | It can be used in tough environment |

7 | There are various interfaces that are easy to use |

8 | RS232 communication interface |

FAQ

Q: What's your products?

A: Cnc controller ,servo system ,servo spindle system ,robot arm

Q: What’s the MOQ for your products?

A: Usually 1 carton .

Q: What’s the payment terms?

A: T.T with 30% downpayment,70%before shipment.or L/C at sight.

Paypal or West Union also accept.

If you have another question, pls feel free to contact us as below