SZGHTECH Multifunctional automation Small CNC lathe Machine

Spindle: Using angular contact high-speed bearings, the rated speed is 3500 rpm, which is suitable for large cutting volume processing. The clamping method can be changed from hydraulic to pneumatic clamping according to the customer's different use occasions. If there are high-speed and high-gloss requirements, a 6000-rpm high-speed electric spindle can be selected.

Rotating cylinder: The standard hydraulic rotating cylinder makes the clamping force larger, more stable and has a long service life. It can be replaced with pneumatic clamping according to actual conditions.

Screw: It adopts high-quality grinding-grade ball screw, and can be equipped with Taiwan Shangyin or German Rexroth according to actual needs.

Guide rail: Taiwan Shangyin guide rail is used, and configurations of other brands can be selected according to actual needs.

It can be used with the tool holder to process long-axis workpieces.

It can be equipped with oil bath feeding, heavy hammer feeding and fully automatic loading rack device to achieve fully automated processing.

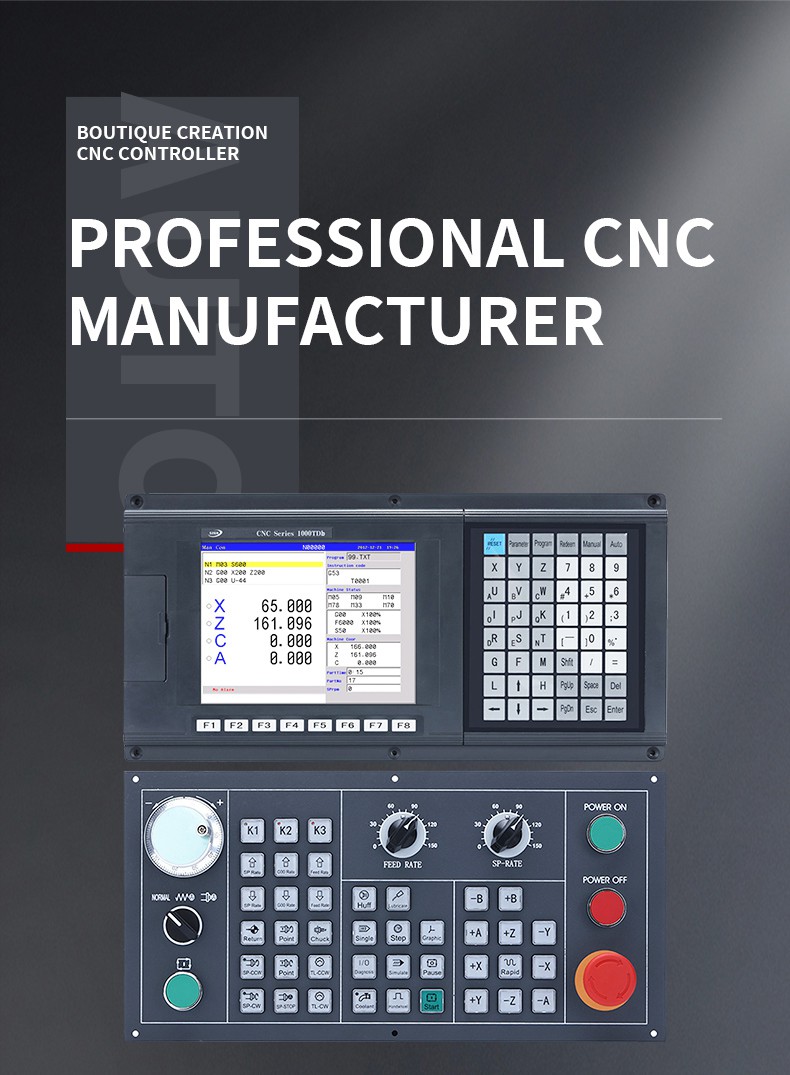

Features of Matched CNC Controller

1)2-5 Axis Fully English Type CNC lathe controller;

2) 800x600 8.4 inch real color LCD displayer;

3) Electric Turret & Binary code turret,Max: 99 pcs tools;

4) Support ATC , Macro function and PLC function;

5) Max speed is 60m/min, feeding speed is 24m/min;

6) Adapted servo spindle can realize spindle continous position,rigid tapping,rigid screw processing;

7) High anti-jamming switch power(100V-240VAC 50Hz/60Hz -> 24VDC);

8) 64MB Memory , 56M user store room;

9) With USB interface,it supports file operation in flash disk,system configuration and software upgrade;

10) Position Control Mode:Pulse+Direction/AB Phase,Dual Analog voltage output of 0~10V;

11) 32 bits ARM microprocessor+FPGA Technology;

12) Basic I/O: 36X36, can be edited freely;

13) Cutter offset.

If there is a need, please contact us, we will give you the best customized solution!