Product Description

3-axis CNC milling drilling machine - Model SZGH-650 (The CNC Controller Model is GH-1000MC-3)

SZGH-650 is a powerful 3-axis milling machine with the following features:

1) High precision and stability: SZGH-650 adopts advanced numerical control technology and a precision position feedback system, which can achieve high-precision machining and motion control. It can precisely control the movement of the milling cutter in three directions, ensuring machining accuracy and surface quality

2) Multi-functional machining capacity: This milling machine has a wealth of machining functions, such as boring, milling, drilling, etc. It can adapt to the processing needs of a variety of complex parts, including mold manufacturing, parts processing, and sample making.

3) Efficient production efficiency: The SZGH-650 is equipped with fast positioning and automatic feeding for fast and precise machining. It also supports automatic tool changes and machining trajectory optimization, reducing the need for manual intervention and increasing productivity

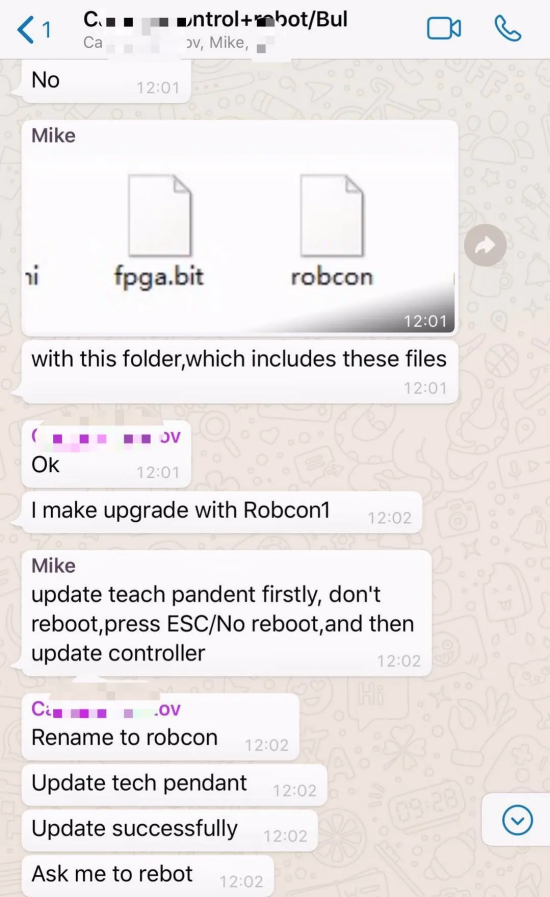

4) User-friendly operator interface: The machine features an intuitive graphical interface and an easy-to-operate control panel that enables the operator to easily set and adjust machining parameters. It provides easy-to-understand menus and instructions, reducing operator training costs and increasing work efficiency.

GH-1000MC-3

GH-1000MC is a CNC controller specially designed for 3-axis milling machines, with the following features:

1) Multi-axis control capability: The GH-1000MC supports 3-axis control, namely X-axis, Y-axis, and Z-axis. This allows the milling machine to perform precise machining movements in three directions, enabling precision machining of complex parts.

2) High precision and stability: The controller adopts an advanced control algorithm and precision position feedback system, which can achieve high-precision position control and motion control. It enables precise control of the movement and cutting of the milling cutter on the workpiece to ensure consistent machining accuracy and surface quality.

3) Powerful machining functions: GH-1000MC has a wealth of machining functions, including automatic tool transformation, tool radius compensation, machining trajectory optimization, etc. It can automate multiple machining steps according to the processing parameters and paths set by the user, improving production efficiency and reducing human error.

4) User-friendly operator interface: The controller is equipped with an intuitive graphical interface and a user-friendly operator panel that enables the operator to easily set and adjust machining parameters. It provides easy-to-understand menus and instructions, reducing operator training costs and increasing work efficiency.

5) Safety and reliability: The GH-1000MC focuses on safety and has a variety of safety protection functions, such as emergency stop buttons, overload protection, and temperature monitoring. It can respond to abnormal situations and shut down in a timely manner, protecting the safety of operators and equipment.

Machine Features

|

|

|

|

| The high-rigidity cast base and gantry provide confidence of perfect stability and high precision when operating. | 3.7kW, 6000 RPM spindle motor with BT40 shank, equipped with a 10-station linear pneumatic tool changer, which can change tools more efficiently. |

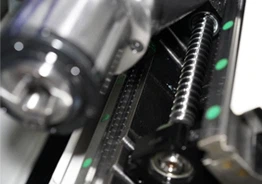

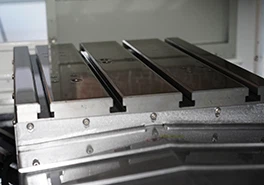

The drive structure uses high-precision screw guides and a fully enclosed protective cover for three axes prevents cutting fluid and iron chips from entering the screw guides during machining, reducing the workload of maintenance. |

|

|

|

|

|

| Size 500* 400mm T-slot table for handling the workpiece up to 200kg. | Carousel type tools changer, tooling number up to 10 pcs, automatic exchange. | Equips with auto lubrication system to ensure transmission system smooth and long-term running. | SZGH CNC system co-works with quality electrical parts to provide a rapid-operation and durable use. |

Applications

The vertical machining center (VMC) is an advanced manufacturing machine tool that can perform a variety of machining operations with high precision, high quality, and high surface finish. VMC-650 vertical machining center is designed and specialized in the operations of milling, boring, drilling, tapping, etc for small parts in one single setup. VMC-650 is truly cost-effective and more and more popular in the machining and tooling industries.

|

|

|

|

|

Company Profile

1) 11 years of supplier history

2) Focus on CNC systems and industrial robots

3) Rich export experience and program customization ability

Advantages of our company:

1. Supplier History: We are an 11-year-old supplier with a proven reputation and experience in the industry.

2. Areas of Focus: We specialize in CNC systems and industrial robotics and have in-depth knowledge and expertise in these technical areas.

3. Export experience: We have rich export experience, are familiar with international market needs and standards and can provide customers with global solutions.

4. Customized solutions: We are able to provide customized solutions according to the needs and pain points of customers to meet the specific requirements of customers.

5. Improve efficiency: Our CNC systems and industrial robotics solutions help customers improve production efficiency, reduce costs, and achieve greater competitiveness.

6. Technical support: We provide comprehensive technical support and after-sales service to ensure that customers receive timely support and assistance during use.

Through our expertise, experience, and ability to customize solutions, we are committed to solving the challenges faced by our customers in the field of CNC systems and industrial robots, helping them improve production efficiency and gain a competitive advantage.

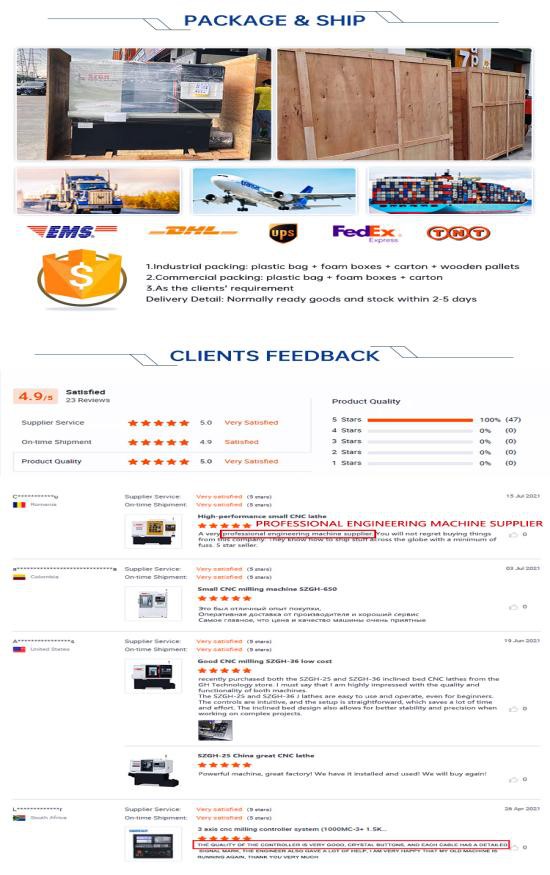

Delivery And After-Sales Service

1) Efficient delivery: Our company is based on efficient supply chain management and is able to deliver timely goods to ensure that customers receive the required equipment and parts on time. We understand the urgent need for fast delivery and are therefore committed to reducing lead times so that customers can quickly start and improve their lives.

2) Timely after-sales support: We know the after-sales service.

3) Customer Satisfaction: Our company takes customer satisfaction as its core value. We always pay attention to the needs and feedback of our customers and strive to exceed expectations to ensure that customers are satisfied with our products and services. We actively listen to our customer's opinions and suggestions and continuously improve our products and services to meet the needs of customers.