Features of SZGH-650 milling machine

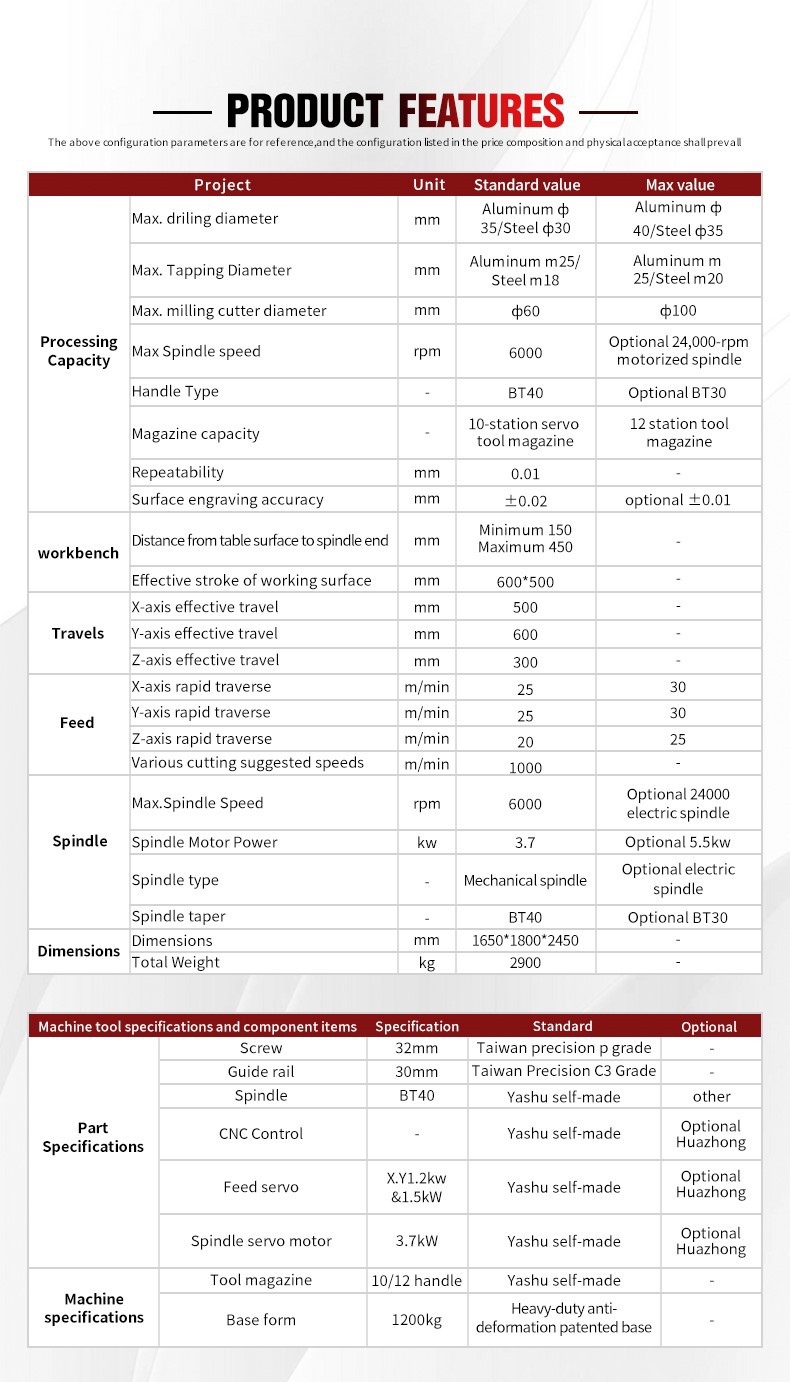

1. Wide range of processing

In addition to processing simple planes, milling machines can also process complex three-dimensional surfaces, contours, etc., which are suitable for mass production and single-piece small-batch production.

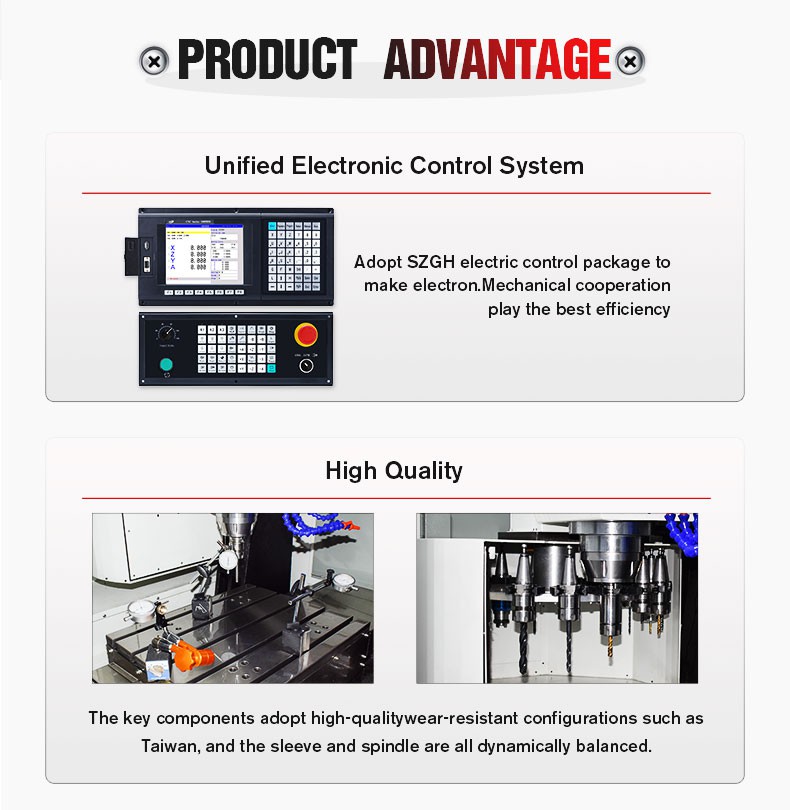

2. Strong adaptability

Milling machines can be equipped with a variety of different milling cutters to meet different processing needs. There are many types of cutters, such as end mills, face mills, angle milling cutters, etc., which can adapt to a variety of processing tasks.

3. Automation and CNC

Modern milling machines, especially CNC milling machines (CNC milling machines), can complete complex automated processing processes through computer control, greatly improving processing accuracy, efficiency and the level of automation of production.

4. Fast processing speed

The processing speed of the milling machine is relatively high, especially under the optimization of the CNC system, which can achieve fast cutting and efficient processing, suitable for mass production.

5. Higher tool life

Due to the relatively stable cutting conditions of the milling machine and the rich cooling system support, the tool life is usually longer, reducing production costs.

6. Process adaptability

Milling machines are suitable for processing different types of parts, such as complex three-dimensional surfaces, high-precision hole processing, etc. They are ideal for manufacturing workpieces with complex shapes.