Product Description

Mini 5-Axis CNC Milling Machine-SZGH-650 5-Axis Milling Machine (The CNC Controller Model is SZGH-CNC1000MDb-5)

1. Multi-axis control: By simultaneously controlling the X, Y, and Z axis and rotating A and B axes, multi-axis linkage is realized, so that the machine can accurately cut and process in multiple directions.

2. High-precision machining: The ability to handle complex surfaces, fine details, and special shapes ensures high precision and high-quality machining results.

3. Fast and efficient: With high-speed cutting and high processing efficiency, reduce manufacturing cycle and improve production efficiency.

4. A variety of processing steps: The 5-axis milling machine can realize drilling, milling, grooving, cutting, and other processing steps to meet different processing needs.

5. Flexible and diverse machining methods: More complex shapes and contours can be achieved by oblique cutting, circumferential interpolation, spiral interpolation, etc.

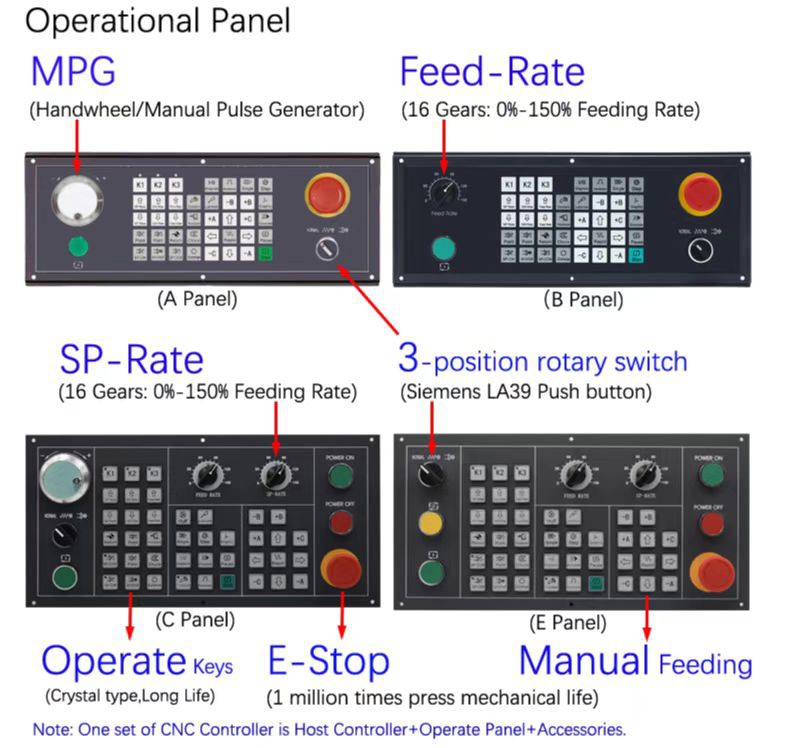

SZGH-CNC1000MDb-5 (It can support one of the four panels A, B, C, and E to choose from)

|

|

|

●1)3-5 Axis standard and updated series CNC milling and router controller

●2) CNC1000MDc series support absolute type servo system & linear scale

●3) 800x600 8.4 inch real color LCD displayer

●4) Support ATC, Macro function, and PLC function

●5) 2MHz Pulse Output Frequency, Default Pulse equivalent is 1um.

●6) Support C-axis positioning, rigid tapping, threading of spindle

●7) High anti-jamming switch power(220VAC -> 24VDC&5V)

●8) 128MB Memory,100Mb user store room

●9) With a USB interface, for upgrading & copy programs

●10) Analog voltage output of 0~ 10V in two channels, support double spindles

●11) Support Position Feedback with linear scale( Differential signal/RS422)

●12) Basic I/O: 56X32 ,PLC On-line Display,Monitor & Design

●13)Support Linear tool magazine, umbrella, Arm type tool magazine

●14) English menu, program, and interface, full-screen edition

●15)Support the macro variable dialog box & Run the program by input points

●16) Built-in screw compensation, Reverse backlash compensation

●17) CNC1000MDi support Modbus/EtherCAT/PowerLink/Increment type Servo System

Application: CNC Boring machine, CNC woodworking machine, CNC Milling machinery, CNC drilling machinery, and especially automatic equipment.

Machine Features

|

|

|

|

| The high-rigidity cast base and gantry provide confidence of perfect stability and high precision when operating. | 3.7kW, 6000 RPM spindle motor with BT40 shank, equipped with a 10-station linear pneumatic tool changer, which can change tools more efficiently. | The drive structure uses high-precision screw guides and a fully enclosed protective cover for three axes prevents cutting fluid and iron chips from entering the screw guides during machining, reducing the workload of maintenance. |

|

|

|

|

| Size 600* 500mm T-slot table for handling the workpiece up to 200kg. | Carousel type tools changer, tooling number up to 10 pcs, automatic exchange. | Equips with auto lubrication system to ensure transmission system smooth and long-term running. | SZGH CNC system co-works with quality electrical parts to provide a rapid-operation and durable use. |

Applications

- Mechanical parts with complex contours: The mini 5-axis CNC milling machine can process various mechanical parts, such as shafts, gears, connectors, etc., with high precision and complex contour requirements.

- Mold parts: This milling machine is suitable for manufacturing mold parts, such as injection molds, die-casting molds, embossing molds, etc., and can process mold parts with complex shapes.

|

|

|

Company Profile

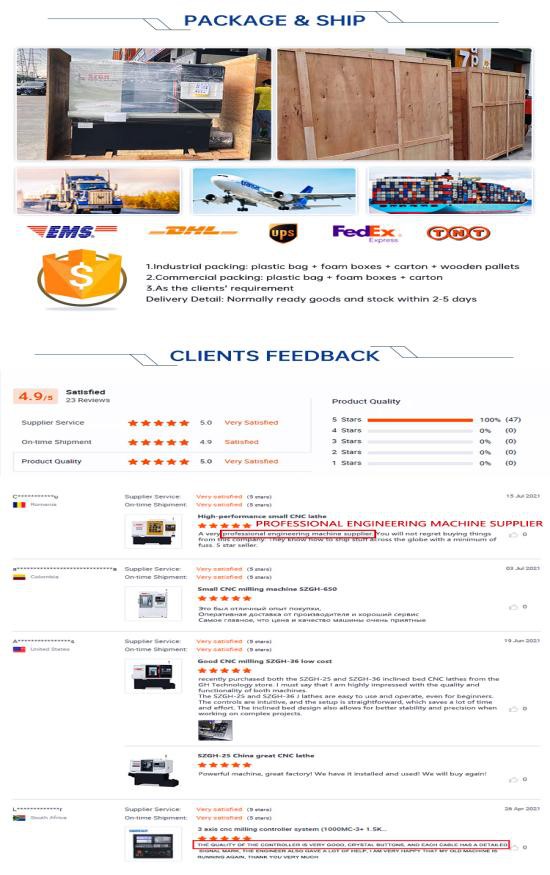

- Supplier history: We are an 11-year-old supplier focusing on CNC systems, industrial robots, and machine tools.

- Export experience: We have rich export experience in these fields and are familiar with international market needs and standards.

- Solution experience: We are characterized by providing customized solutions to help customers solve various challenges.

Delivery And After-Sales Service

FAQ

Q1: Please provide the machine type and specification range that your company can provide.

A1: Our company provides many types of machine tools, including lathes, milling machines, grinding machines, drilling machines, etc. The range of specifications covers different workpiece sizes and machining requirements. Please let us know your specific needs and we will provide them

Q2: Please provide the price and delivery period of the machine tool.

A2: The price and delivery cycle of the machine tool vary according to the specific model, configuration, and quantity. In order to be able to give an accurate quotation and delivery time, we need to know the details such as the model, specifications, and quantity of the machine you need.

Q3: Does the machine tool provided by your company have a warranty? How long is the warranty period?

A3: Yes, we provide warranty service for the machine tools provided. The warranty period depends on the specific machine model and the contract. Typically, we offer a standard warranty of 12 months. During the warranty period, we will be responsible for repairing or replacing faults caused by manufacturing defects. The detailed warranty terms will be clearly stated in the formal contract.

Q4: Does your company provide machine tool installation and commissioning services?

A4: Yes, we provide installation and commissioning services for machine tools. We have an experienced technical team that will ensure that the machine is properly installed and commissioned to ensure its normal operation. We will provide operational training to help your staff become familiar with machine operation.

Q5: Does your company provide after-sales service and technical support for machine tools?

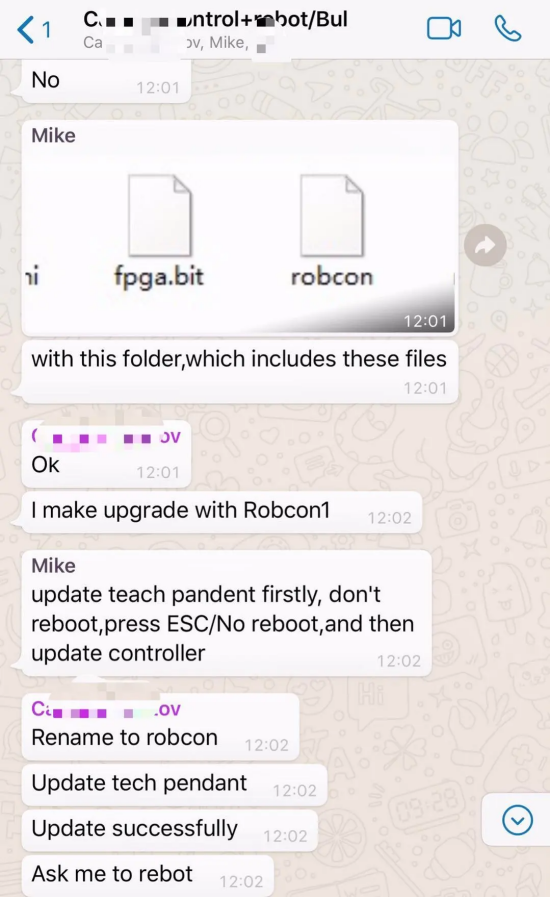

A5: Yes, we provide comprehensive after-sales service and technical support. If you encounter any problems during the use of the machine, our technical team will provide quick response and professional support. We offer remote support, troubleshooting, and repair services to ensure your machine remains efficient.

Q6: Does your machine meet international quality and safety standards?

A6: Yes, our machine tool products meet international quality standards and safety standards. We produce in strict accordance with the requirements of ISO certification and CE certification and ensure that machine tools meet safety standards during design, manufacture, and use. We can provide the corresponding certifications and certificates as you

Q7: Please indicate the machining capacity and accuracy of the machine.

A7: Our machines have a wide range of machining capabilities, including milling, drilling, turning, etc. Machining capacity and accuracy depend on the specific machine model and specifications. We can provide detailed technical data, including processing capacity.

Q8: Can you provide a customer story or reference?

A8: Yes, we can provide customer cases or references to show the application and effect of our machine tools in different industries. This will help you better understand the quality and performance of our products.