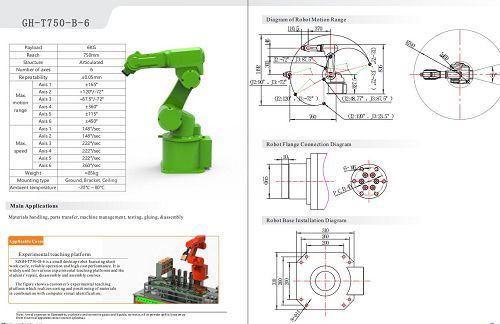

Multifunction six Axis Mult-Joint collaborative robot arm simiar Kuka robot arm for grinder industrial robot arm

GH-T750-B-6 is our mini General-purpose Series robot arm,can be do 750 mm-2950mm reaching ;widely used for Materials handling, parts transfer, machine management, testing, gluing, &assembly ; with favorable price, wide application, safe and efficient, is a product worth having ,It is a light-weight body with a suitable arm length and a moderate load weight, reaching out to customers

Applicable Cases

launched by the company. With a payload of 6 kg and a reach of 1500 mm, it is generally integrated with various non-standard turntables or hanging equipment to form work stations

The figure shows the hanging line tracking and painting solution provided for a customer. It not only significantly reduces labor cost but also improves the yield.

Payload | 6kg |

Reach | 750mm |

Axes | |

Application | Materials handling, parts transfer, machine management, testing, gluing, &assembly |

Special Service | 1. We can customize the standard color as you need! |

After Warran | Video technical supports , Online supports |

Lab aging test GH-T750-B-6 is a small robot featuring short work cycle, reliable operation and high cost performance. Previous industrial applications prove its outstanding performance, high added value, quick return on investment and significant increase of productivity The figure shows a customer's field application. This robot is used in the customer's aging test lab. |  |

Applicable Cases Experimental teaching platform SZGH-T750-B-6 is a small desktop robot featuring short work cycle, reliable operation and high cost performance. It is widely used for various experimental teaching platforms and the students' repair, disassembly and assembly courses The figure shows a customer's experimental teaching platform which realizes sorting and positioning of materials in combination with computer visual identification. |  |

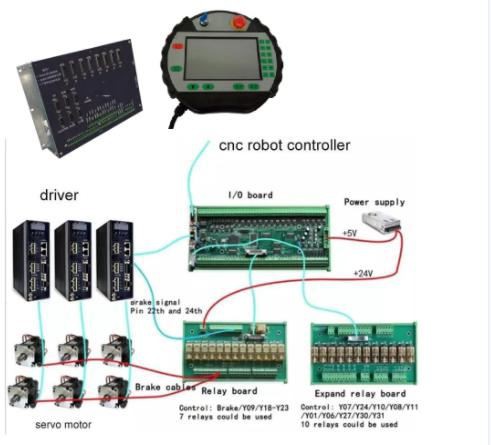

Robot controller systems

1)Structural optimization algorithm suitable for the body control of various types of structure.

2)Modular setting of functionssuitable for diverse applications. 8-axis control realizes the control of external axes (traveling axes and positioner).

3)Suitable for multiple increments; absolute servo.

Open structure for synchronization of international technology and extension of functions.

4)Software PLC functions facilitate logic control.

Process functions make programming easy.

5)Improved computer bus connection ensures reliability and practicability.

6)Safety module ensures safe production of the robots.

Industrial standards &reliable stability.

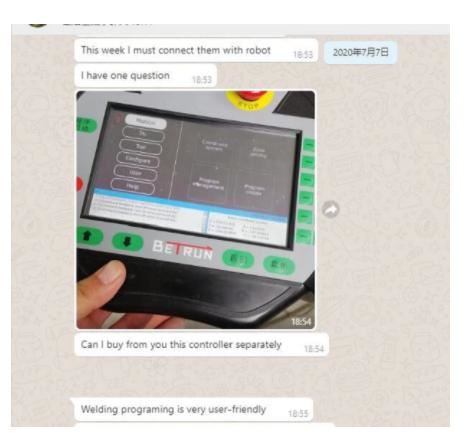

Best & Professional after- sales supports

Our company have very professional engineers teams ;

We can provide the professional after -sales service to our all clients ;

Best feedback form our Clients !

Best supports !! Quicly reply !!

Buy at ease , use at ease !!!

FAQ

Q: Do you have the test and audit service?

A: Yes, we can assist to get the designated test report for product and the designated factory audit report.

Q: What’s is your shipping service?

A: We can provide services for vessel booking, goods consolidation, customs declaration, shipping documents preparation and delivery bulk at the shipping port.

Q: What’s your tem of the delivery?

A: Our ordinary delivery term is FOB SHENZHEN. We also accept EXW, CFR, CIF, DDP, DDU etc. We’ll offer you the shipping charges and you can choose the one which is the most convenient and effective for you.

Q: Which shipping way can you provide?

A: We can provide shipping by sea, by air and by express.