SZGH-B1850-3C-4

Product Description

Payload | 30kg |

| Structure | Articulated |

Axes | 4-11 Axes |

| Reach | 1850mm |

| Weight | 230kg |

Special Service | 1. We can customize the standard color as you need! |

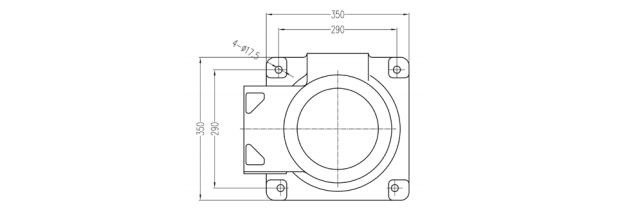

| Mounting type | Horizontal |

| Transport Package | Wooden Box |

| Main Applications | Materials Handling, Parts Transmission ,Stacking, Deburring, Cutting. |

Feature Of High Quality Material Handling Robots Arm Kits

Load-bearing capacity: 1850mm handling robots usually have a larger load-bearing capacity and can carry heavier objects for handling and movement.

Accuracy and sensitivity: The height of the robot also has certain requirements for the accuracy and sensitivity of the robot. It may require a high-precision positioning system for precise manipulation in tight spaces.

Robot structure: The 1850mm handling robot may adopt a multi-joint structure, which can realize multiple degrees of freedom of movement, and can flexibly adapt to different handling and operation requirements.

Control system: The robot needs to be equipped with an advanced control system and algorithm, which can realize functions such as autonomous navigation, obstacle avoidance, path planning, etc., to ensure the efficient operation of the robot in a busy production environment.

Safety: Robots must meet certain safety standards to ensure safety for people and equipment during production. Typically, a robot may be equipped with various sensors and safety devices to ensure safe operation.

Robot Controller Systems

| 1)Structural optimization algorithm suitable for the body control of various types of structure. 2)Modular setting of functionssuitable for diverse applications. 8-axis control realizes the control of external axes (traveling axes and positioner). 3)Suitable for multiple increments; absolute servo. Open structure for synchronization of international technology and extension of functions. 4)Software PLC functions facilitate logic control. Process functions make programming easy. 5)Improved computer bus connection ensures reliability and practicability. 6)Safety module ensures safe production of the robots. |  |

Complete Solution For Industrial Robot Arm

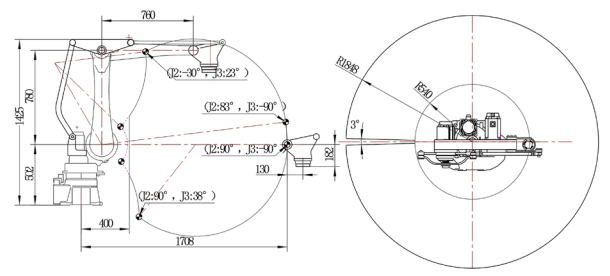

Robot Motion Range

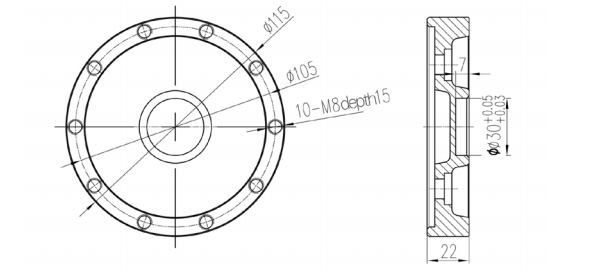

Robot Flange Connection

If you have another question or you have any need, pls feel free to contact us as below. We will give you a warm and positive reply.