Product Description

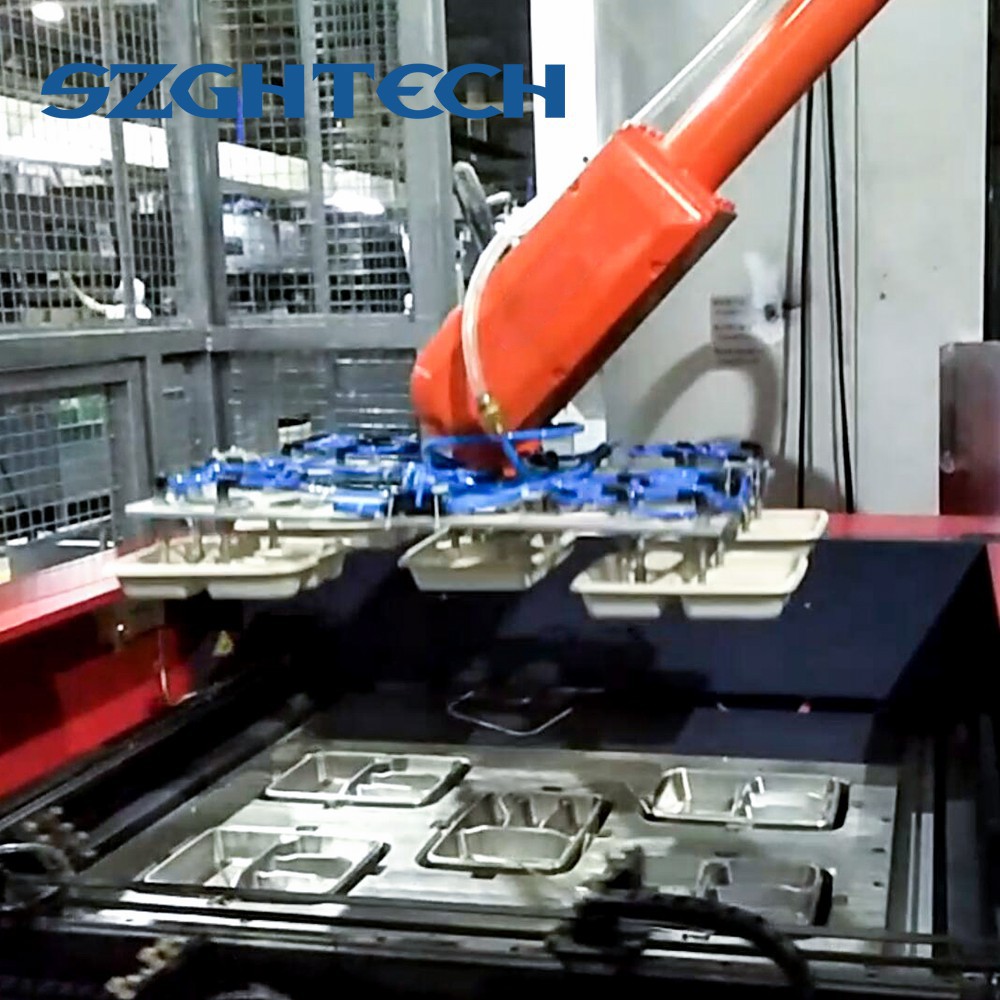

The pick-up robot is an automated material handling system that autonomously picks up workpieces from the storage area and places them on the production line.

1) The robot system has the characteristics of high efficiency, precision and reliability, which can greatly improve production efficiency, reduce labor costs and reduce material loss.

2) The loading and unloading robot adopts advanced machine vision technology and control algorithms, which can automatically identify and grasp workpieces of various shapes and weights according to real-time changing production needs, and complete handling and placement in a very short time.

3) The robot system is equipped with multiple safety functions such as safety sensors and emergency stop switches to ensure the safety of operators and machines.

4) Loading and unloading robots are suitable for various manufacturing fields, such as automotive, electronics, food and other industries.

5) It works seamlessly with other equipment on the production line for a fully automated production process.

6) The programmability and flexibility of the robot also make it have the ability to adapt to different production needs, which can be modified and upgraded at any time.

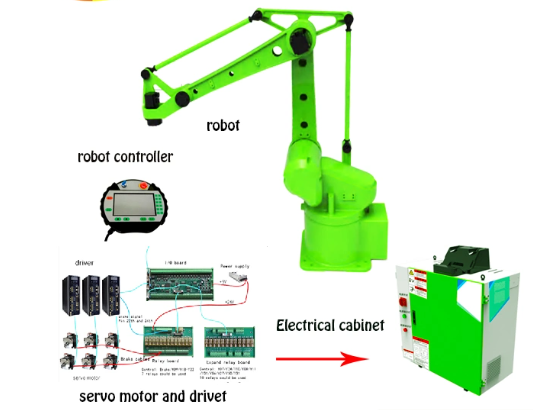

Packing list :

1. robot 4 axis cnc controller 1 sets

2. 30 KG payload 1850MM handing robot arm

3. Electrical cabinet

5. Operation manual, cable required

6. Servo motor, driver and cable

|

Payload | 30kg |

| Reach | 1850mm | |

| Axes | 4 axes | |

| Application | Materials handling, parts transfer, palletizing, deburring &cutting | |

| Special Service | 1. We can customize the standard color as you need! 2. We can customize your company logo! |

|

| After Warran | Video technical supports , Online supports |

Product parameter(specification)

| Arm | Axis 1 | Axis 2 | Axis 3 | Axis 4 |

| Max motion range | ±170° | +80°/-25° | +80°1-25° | ±360° |

| Max speed | 148°/sec | 148°/sec | 148°/sec | 222°/sec |

product features

- Large working space: The arm length of this robot is 1850mm, which can cover a large working space, suitable for large production lines and storage systems.

- High precision: The robot adopts advanced sensors and control algorithms, has high-precision positioning and grasping capabilities, and can complete delicate handling and assembly tasks.

- High load capacity: The robot has a high load capacity and can withstand a maximum material weight of 20 kg.

- Strong flexibility: The robot's arm can rotate 360 degrees without dead angles, and can adapt to different angles and directions of work scenarios, with strong flexibility and adaptability.

- Easy to operate: The robot is equipped with a humanized control interface and operation guide, which is convenient for operators to quickly get started, and has one-button automatic operation and debugging functions, simplifying the operation process.

Applications(strong adaptability and flexibility, and can provide efficient, accurate and reliable material handling services for various manufacturing fields)

1. Automotive manufacturing: It can be used for the handling and assembly of parts on the automotive production line.

2. Electronic manufacturing: can be used for the assembly, packaging and handling of electronic components.

3. Food processing industry: can be used for raw material handling and packaging on food processing lines.

4. Warehousing and logistics industry: It can be used for tasks such as loading and unloading and stacking of goods.

Installation Guarantee

(1)Ensure human safety: When the robot is running, people need to be prohibited from entering its operating area. Operators need to wear appropriate personal protective equipment, such as safety helmets, safety shoes, gloves, etc., to ensure the safety of personnel

(2)Comply with operating procedures: Operators should operate in accordance with robot operating procedures, strictly abide by the operation steps and precautions, and prevent misoperation or omission.

(3)Keep the equipment clean: The operator should clean and maintain the robot frequently to ensure that the equipment is in good working condition and avoid safety problems caused by equipment failure.

(4)Regular inspection of equipment: Operators need to regularly inspect the robot's critical components and safety systems to ensure its proper operation and reliability.

(5)Shutdown protection: Operators need to stop in time when the robot fails or abnormal situations, and take necessary safety measures to avoid accidents.

(6)Power failure protection: When maintaining, maintaining or debugging the robot, the operator needs to cut off the power supply first and carry out corresponding operational measures to ensure the safety of personnel and equipment.

(7)Record maintenance records in time: Operators need to record the maintenance, maintenance and fault handling of robots in time for future maintenance and management.