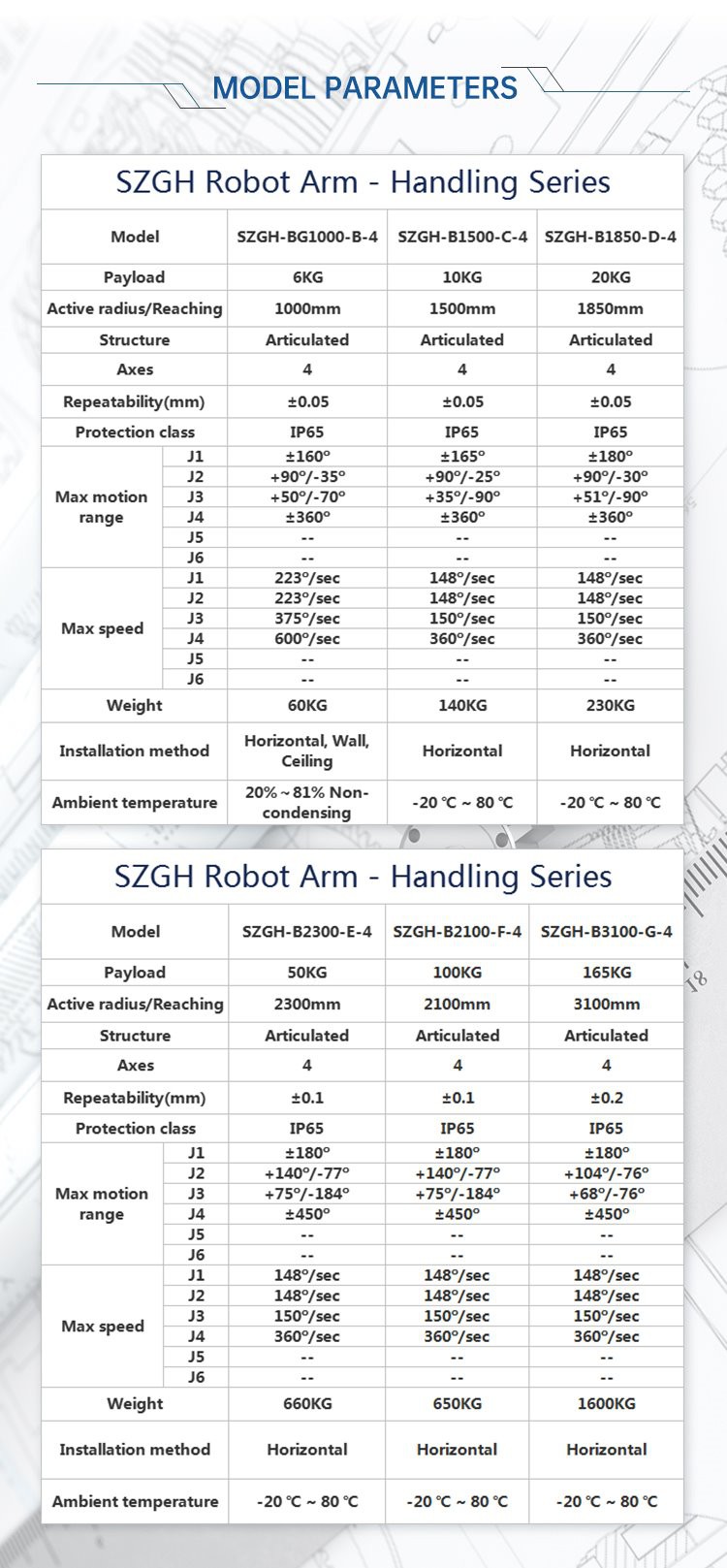

| Model | SZGH-B1500-C-4 |

Payload | 10kg |

| Structure | Articulated |

Axes | 4 |

| Reach | 15000mm |

| Weight | 220kg |

Mounting type | Horizontal |

| Ambient temperature | -20°C~80°C |

| Repeatability | ±0.05mm |

| Application | Materials handling, parts transfer, palletizing, deburring &cutting |

Special Service | 1. We can customize the standard color as you need! |

| Easy to operate Simple and easy to use, it can be used normally after setting through a simple graphical parameter interface. The palletizing function can be complet ed with a minimum of 4 lines of code. |

Easy to debug According to the actual trajectory, the corresponding parameters can be adjusted. Clear schematic diagram, select the corresponding stacking layout according to the product layout. |  |

| Wide range of application There are many types of stacking, including matrix, return type, and custom. The approach method can be formulated according to different needs. This function can be used for stacking all regular objects. |

Robot controller systems:

(1) A flexible structure that allows for the synchronization of global technologies and the expansion of functions. Industrial standards and stable performance.

(2) Logic control is facilitated by PLC software functions. Programming is made simple with process functions.

(3) A modular function setting that is appropriate for a variety of purposes. The robots are produced safely thanks to the safety module.

Main Application:

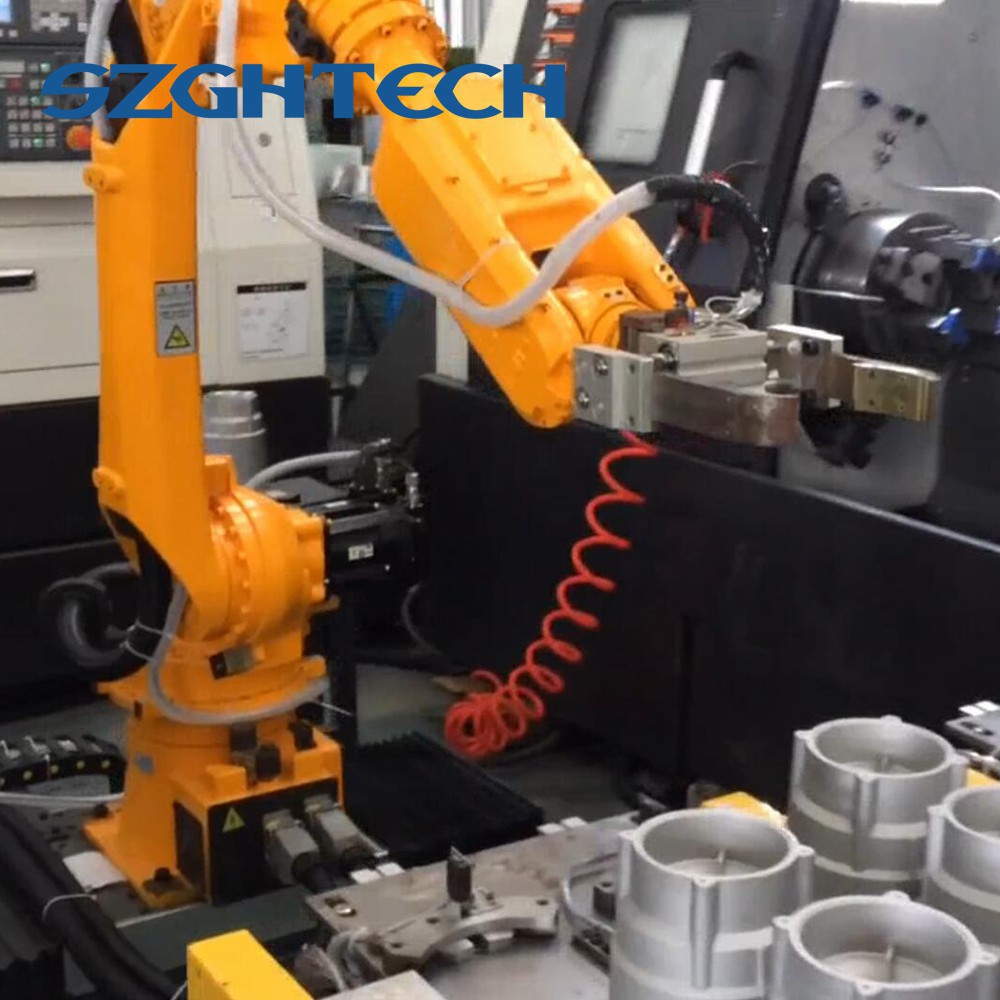

SZGH palletizing robot arm can be used in the fields of machine tool loading and unloading, material handling, parts transfer, palletizing, deburring and cutting.

Applicable Cases: SZGH-B1500-C-4 robot with a 10 kg payload is mainly used for stamping operations of production lines. The figure shows the work site of a customer’s stamping line. The robot can realize loading and unloading extensively in a confined space, thereby significantly enhancing the production efficiency. |  |

Shenzhen Guanhong Technology CO.,LTD(Built in 19 November 2010) is one of the leading CNC & automatic company in China, specialized in designing projects, marketing, and oversea trading, having extensive experience in CNC package solution, Our focus has been on providing the high quality of Industrial Robot Arm, cnc controller, servo motor and driver, spindle motor and driver.

We has professional technical team, strictly product test for high quality guarantee, very competitive quotation, specially we has flexible and convenient payment mode and low cost delivery solution for clients.

Our company tenet "Quality is the life of enterprise ", your satisfy is our greatest achievement.

OUR SERVICE

①CERTIFIED ACTUAL PRODUCTS

We have a zero-tolerance policy for asset recovery vendors.

②LOWEST PACKAGE PRICES

Always offer lower price than other companies.

③PROFESSIONAL TECHNICAL ENGINEER TEAM

Possible fastest response and support to client application demand.

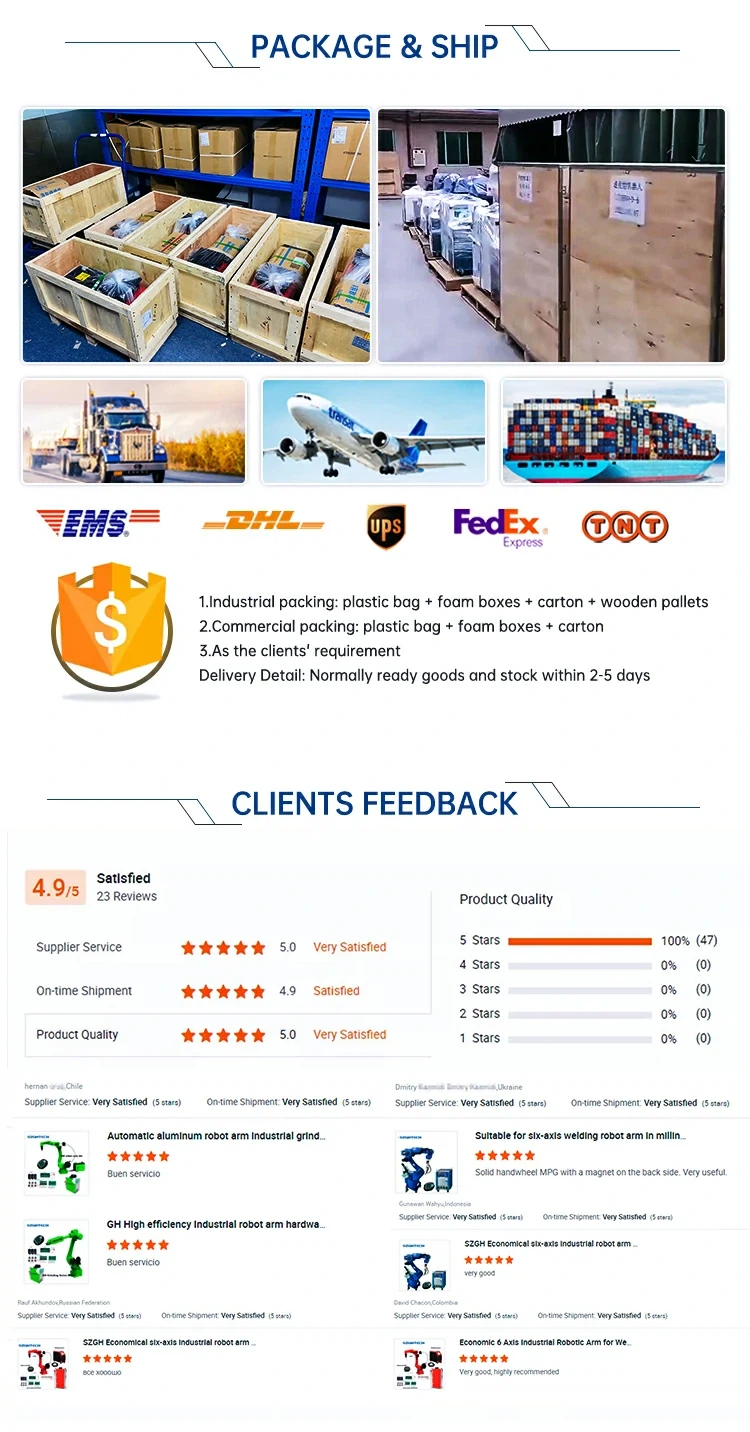

④FAST, PROFESSIONAL AND RELIABLE INTERNATIONAL DEL IVERY

Flexible and low cost delivery solution for clients.

⑤QUALITY GUARANTEE

Free, one-years warranty and life -long maintenance. Any quality problem, GuanHong promise to refund.

FAQ

Q1. Do you have any MOQ (minimum order quality)limit?

A: Low MOQ, 1pc for sample checking is available.

Q2. How to proceed an order?

A: Initially, let us know your requirements or application. Besides, We quote according to your requirements or our suggestions. Thirdly, customers confirms the samples and places deposit for formal order. Finally, We arrange the production.

Q3. Is it acceptable to print my logo on the product?

A: Yes. Please inform us formally before our product and confirm the design firstly based on our sample.

If you have another question, pls feel free to contact us as below.