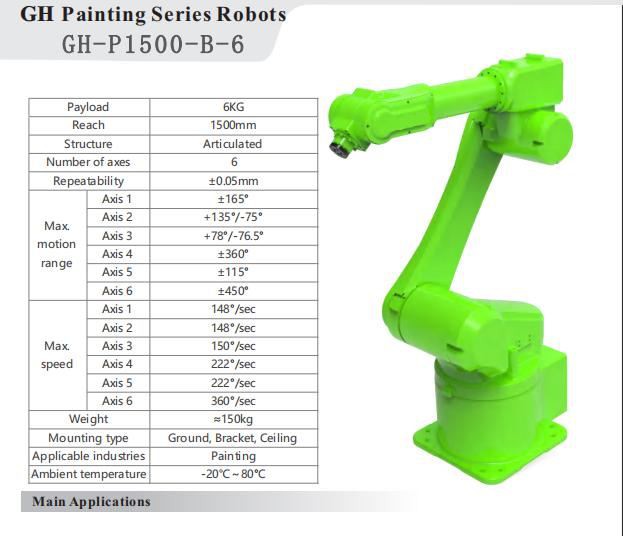

CNC robot controller 6-8 axes industrial robot arm similar KUKA for spray painting robot arm 6 axis

GH-P1500-B-6 is the painting robot is our economical robot arm, with favorable price, wide application, safe and efficient, is a product worth having

GH provide you with completely Robot solutionapplicated to welding, spray, yards , handling,grinding, loading and so on :

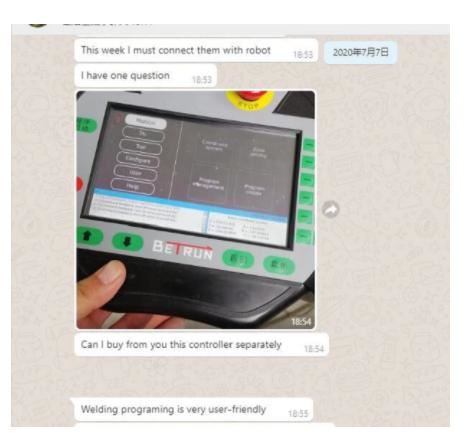

1) CNC welding robot arm support 4 axis to 11 axis ,widely use to welding,painting, move, and plasma cutting, and grinding application. it can save your cost from manpower,also more effeiction and safe operation , higher precision, it can work 24 hours for you!!

Axes | 6 |

Application | Parnting and spraying |

Special Service | 1. We can customize the standard color as you need! |

After Warran | Video technical supports , Online supports |

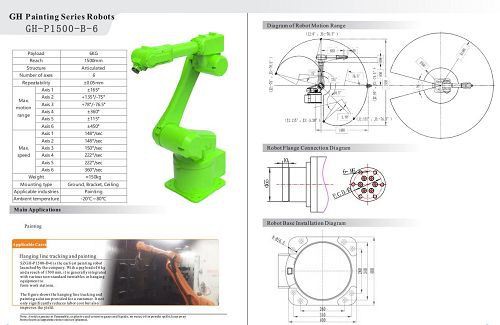

with various non-standard turntables or hanging equipment to form work stations. The figure shows the hanging line tracking and painting solution provided for a customer. It not only significantly reduces labor cost but also improves the yield. |  |

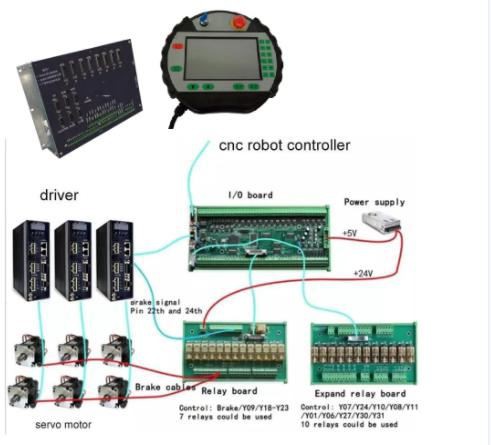

Robot controller systems

1)Structural optimization algorithm suitable for the body control of various types of structure.

2)Modular setting of functionssuitable for diverse applications. 8-axis control realizes the control of external axes (traveling axes and positioner).

3)Suitable for multiple increments; absolute servo.

Open structure for synchronization of international technology and extension of functions.

FAQ

Q: What’s your tem of the delivery?

A: Our ordinary delivery term is FOB SHENZHEN. We also accept EXW, CFR, CIF, DDP, DDU etc. We’ll offer you the shipping charges and you can choose the one which is the most convenient and effective for you.

Q: Which shipping way can you provide?

A: We can provide shipping by sea, by air and by express.

Q: What is your terms of payment ?

A: Payment<=2000USD, 100% in advance. Payment>=1000USD, 70% T/T in advance ,balance before shippment.