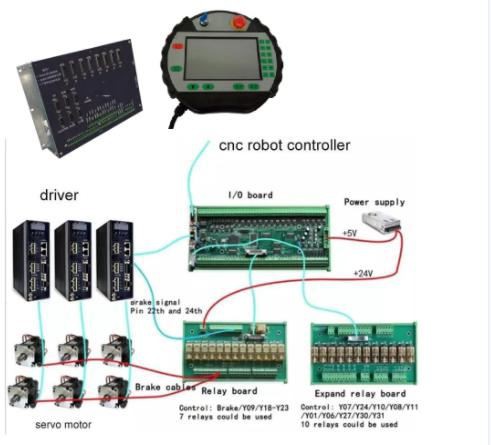

CNC robot controller 6 industrial robot arm similar KUKA for spray painting robot arm 6 axis

GH-P2400-B-6 is the painting robot is our economical robot arm, with favorable price, wide application, safe and efficient, is a product worth having

GH provide you with completely Robot solutionapplicated to welding, spray, yards , handling,grinding, loading and so on :

1) CNC welding robot arm support 4 axis to 11 axis ,widely use to welding,painting, move, and plasma cutting, and grinding application. it can save your cost from manpower,also more effeiction and safe operation , higher precision, it can work 24 hours for you!!

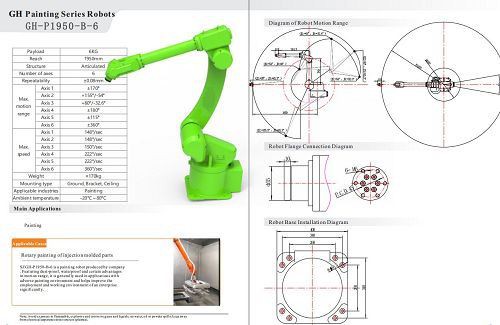

Payload | 6kg |

Reach | 2400mm |

Axes | 6 |

Application | Parnting and spraying |

Special Service | 1. We can customize the standard color as you need! |

After Warran | Video technical supports , Online supports |

Rotary painting of injection molded parts GH-P1950-B-6 is a painting robot produced by company . Featuring dust-proof, waterproof and certain advantages in motion range, it is generally used in applications with adverse painting environment and helps improve the employment and working environment of an enterprise significantlyg |  |

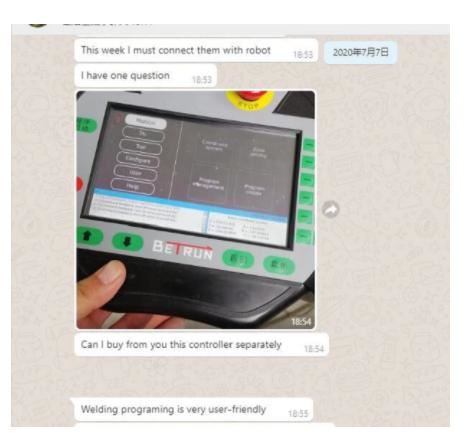

Best feedback form our Clients !

Best supports !! Quicly reply !!

Buy at ease , use at ease !!!

FAQ

Q: Do you provide sample ? Is it free?

A: If the sample is low value, we will provide the free sample with freight collect. But for some high value samples, we need to collect the sample charge.

Q: What is your term of payment?

A: 50% down payment before producing and 50% balance payment before shipping.