Characteristics Of Robotic Arm Painting:

Model No. | SZGH-P1500-B-6 | Specification | 115*115*134 | Structure | Articulated |

Payload | 6KG | Origin | Shenzhen | Weight | 170KG |

Repeatability | 0.05mm | Production Capacity | 1000 Sets /Month | Transport Package | Wooden Box |

Mounting Type | Ground,Bracket,Ceiling | Reaching | 1500mm | Trademark | SZGH |

The robotic arm is an advanced technology for automated factories and many fields in the future, such as: hospitals, logistics, education, agriculture and many more.

At present, SZGH is constantly updating and upgrading our robotic arm. SZGH has its own robot research and development team, and there is no need to submit an application for the upgrade, which is very fast and convenient.

Robotic Arm Spray Painting SZGH-P1500-B-6 is dedicated to spraying; Simple, efficient and safe operation;

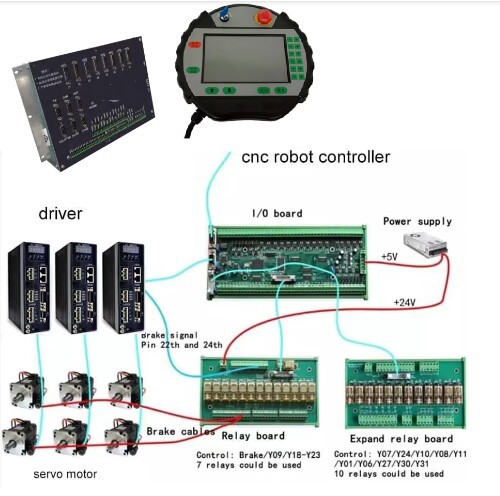

Robot controller systems :

1)Structural optimization algorithm suitable for the body control of various types of structure.

2)Modular setting of functionssuitable for diverse applications. 8-axis control realizes the control of external axes (traveling axes and positioner).

3)Suitable for multiple increments; absolute servo.

Open structure for synchronization of international technology and extension of functions.

4)Software PLC functions facilitate logic control.

Process functions make programming easy.

5)Improved computer bus connection ensures reliability and practicability.

6)Safety module ensures safe production of the robots.

Industrial standards &reliable stability.

The importance of regular maintenance of industrial robots:

The existence of industrial robots replaces the traditional manual mode, improves production efficiency, helps the development of enterprises, and greatly saves the labor cost of enterprises.

However, the robotic arm is used for a long time, and different garbage and debris will be generated in the working environment on site. Just like a car, it is necessary to change the oil at the first order, maintain the battery regularly, maintain the service life of the machine, and avoid some bad glitches that delay the production speed. Regular maintenance of the robotic arm is important.

The process action of the industrial robot needs to be analyzed for 3000-5000h (about 1 year) for a comprehensive system and maintenance, to detect whether there is any abnormality in the control management system and the main body of the robot arm.

The normal life action will increase the cost of enterprise equipment operation and maintenance. Maintenance and maintenance can also prolong the service life of the mechanical arm. For example, the mechanical arm is also composed of mechanical and electrical parts. Mechanical wear is indispensable.

Maintenance methods can slow down the wear and tear of the mechanical arm and regularly organize the detection circuit. Design issues can also prevent the main functional parts of the robotic arm from being burned out. For example, for robotic arm controllers, motors, servo drives, etc.

Regular maintenance of industrial robots:

1.The inspection of industrial robots includes checking whether each bolt is loose or sliding, whether the parts that are easy to loosen and break are normal, and whether the speed change is consistent.

2. Whether the security of the operating system and the protection of the safety devices are flexible and reliable;

3. Check whether the equipment is free from corrosion, collision, pull-out, oil leakage, water leakage, electric leakage, electric leakage, and whether the surrounding ground is clean and tidy.

4. No oil stains and sundries;

5. check the lubrication status, and add lubricating oil regularly and quantitatively.