Model | SZGH-H1850-B-6 |

| Payload | 6kg |

Reach | 1850mm |

Axes | 6-11 Axes |

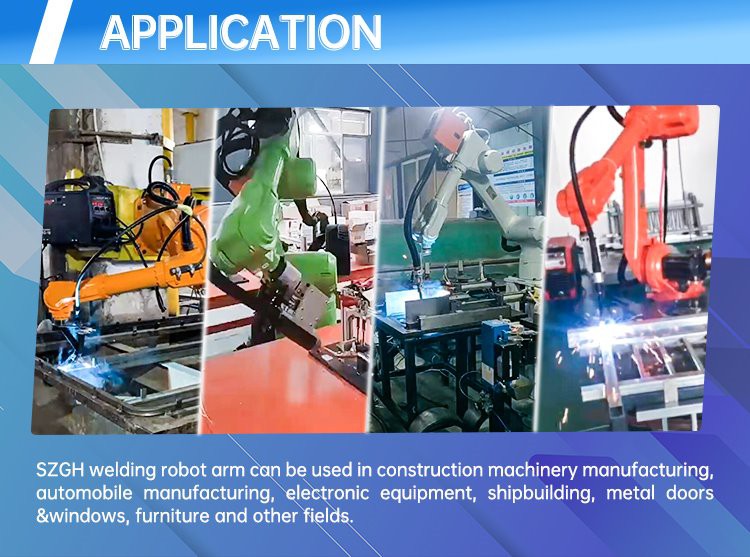

Application | welding |

Special Service | 1. We can customize the standard color as you need! |

After Warran | Video technical supports , Online supports |

1) Suitable for multiple increments; absolute servo. Improved computer bus connection ensures reliability and practicability.

2) Support up to 12 axis control, realizes the control of external axes (traveling axes and positioner).

3) Open structure for synchronization of international technology and extension of functions. Industrial standards & reliable stability.

| Storage | 2 GB |

| No. of controlled axes | 6+6 axes, 6 basic axes +6 external axes |

| Teaching box | Full keyboard+touch screen, mode select switch, safety switch, emergency switch |

| Interface | Multiple encoder signal interfaces, dedicated interface for robot terminal, Ethernet interface, serial communication |

Q: Are you manufacturer or trading company?

A: We are manufacturer for automation robot in Shenzhen city, China.

Q: How long is the delivery time?

A: In general, the delivery time is 7 days for 1 set.

Q: Why should you buy from us and not from other suppliers?

2). You can get good purchase experience and nice technical support;

3). We can provide customized design services quality guarantee, competitive quotation, and honest and reliable business is our tenet.

If you have any questions, pls feel free to contact me below.