Robot Arm 6 Axis Weld Industrial Welding Robotic Arm for Welding Aluminum alloy metal material

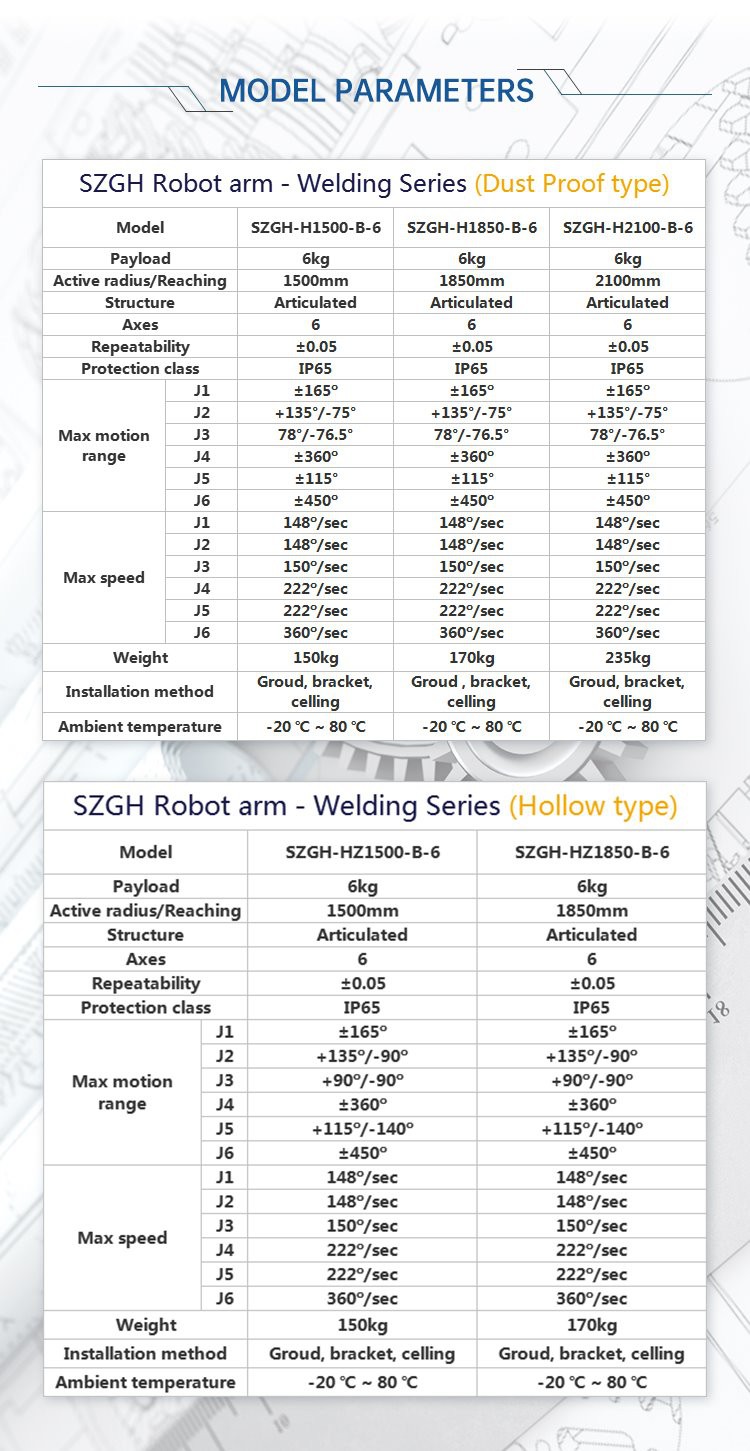

Model | SZGH-H1500-B-6 |

| Payload | 6kg |

Reach | 1500mm |

Axes | 6 |

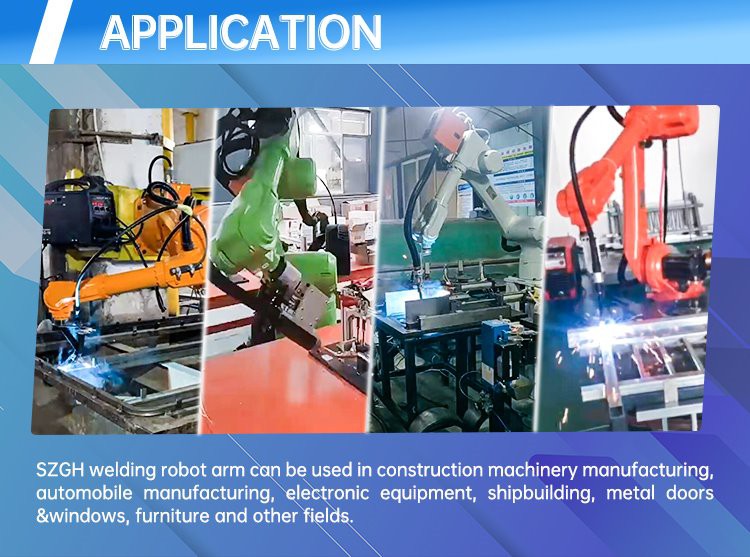

Application | welding |

| Atructure | Articulated |

Special Service | 1. We can customize the standard color as you need! |

Features:

1) Support Chinese, English, Russian, Korean, Vietnamese multi-language display, more language options are under continuous development.

2) Structural optimization algorithm suitable for the body control of various types of structure.

3) Software PLC functions facilitate logic control. Process functions make programming easy.

Q1: Are you a manufacturer or trading company?

A1: A CNC System And Robot Arm manufacturer.

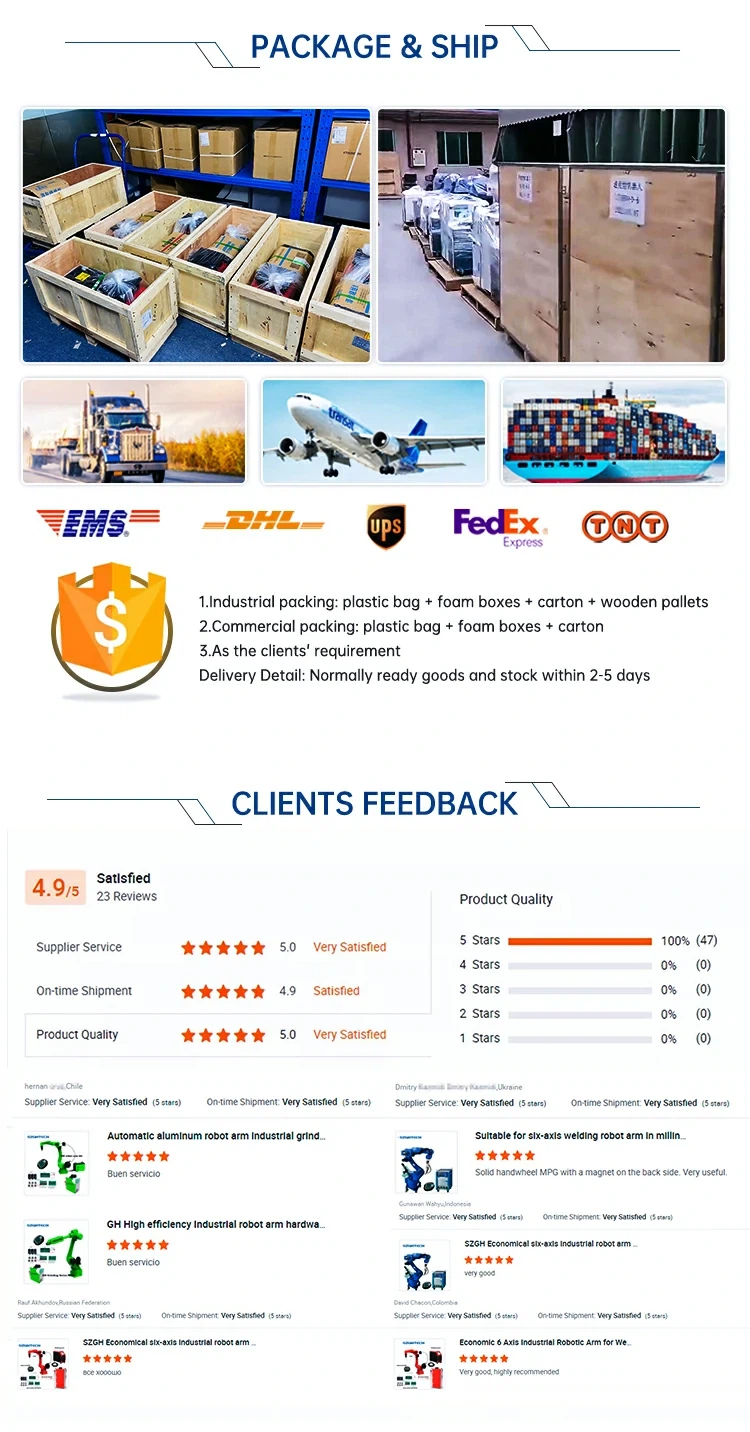

Q2: What about the shipping methods?

A2: For urgent order and light weight, you can choose the following express: UPS, FedEx, TNT,DHL, EMS. For heavy weight, you can choose to deliver the goods by air or by sea to save cost.

Q3: What about the payment methods?

A3: We accept T/T for big amount, and for small amount, you can pay us by Alibaba, PayPal, Western Union, and etc.

Q4: How much does it cost to ship to my country?

A4: It depends on seasons. Fee is different in different seasons. You can consult us at all times.

If you have any questions, pls feel free to contact me below.