Robot Arm 6 Axis High Quality China Industrial Robot Arm MIG Welding Robotic

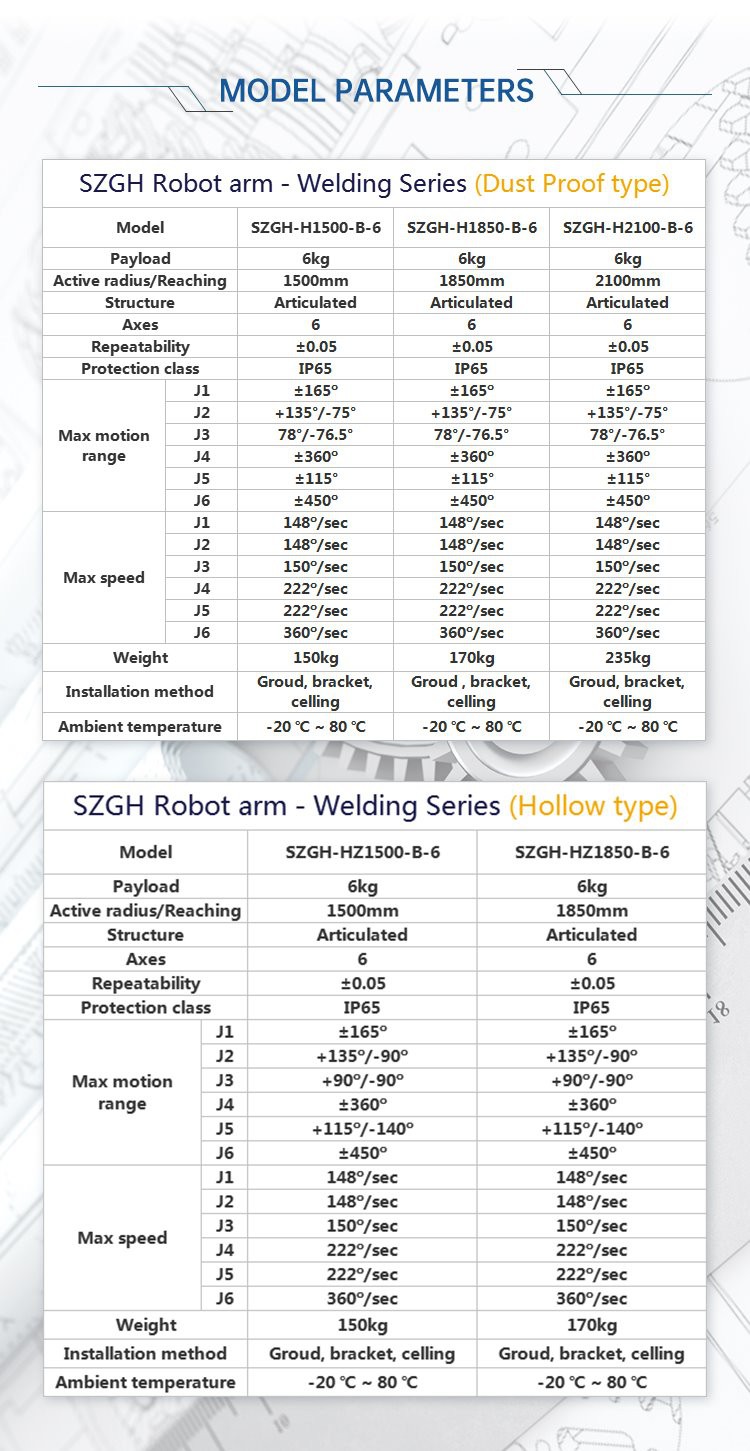

Model | SZGH-H1500-B-6 |

| Payload | 6kg |

Reach | 1500mm |

Axes | 6 Axes |

| Repeatability | 0.05mm |

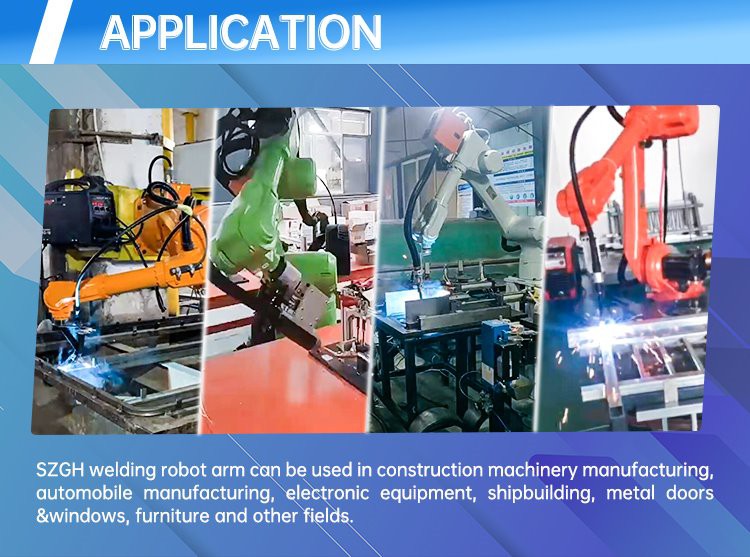

Application | welding |

| Atructure | Articulated |

| Place of origin | Shenzhen City,Guangdong Province,China. |

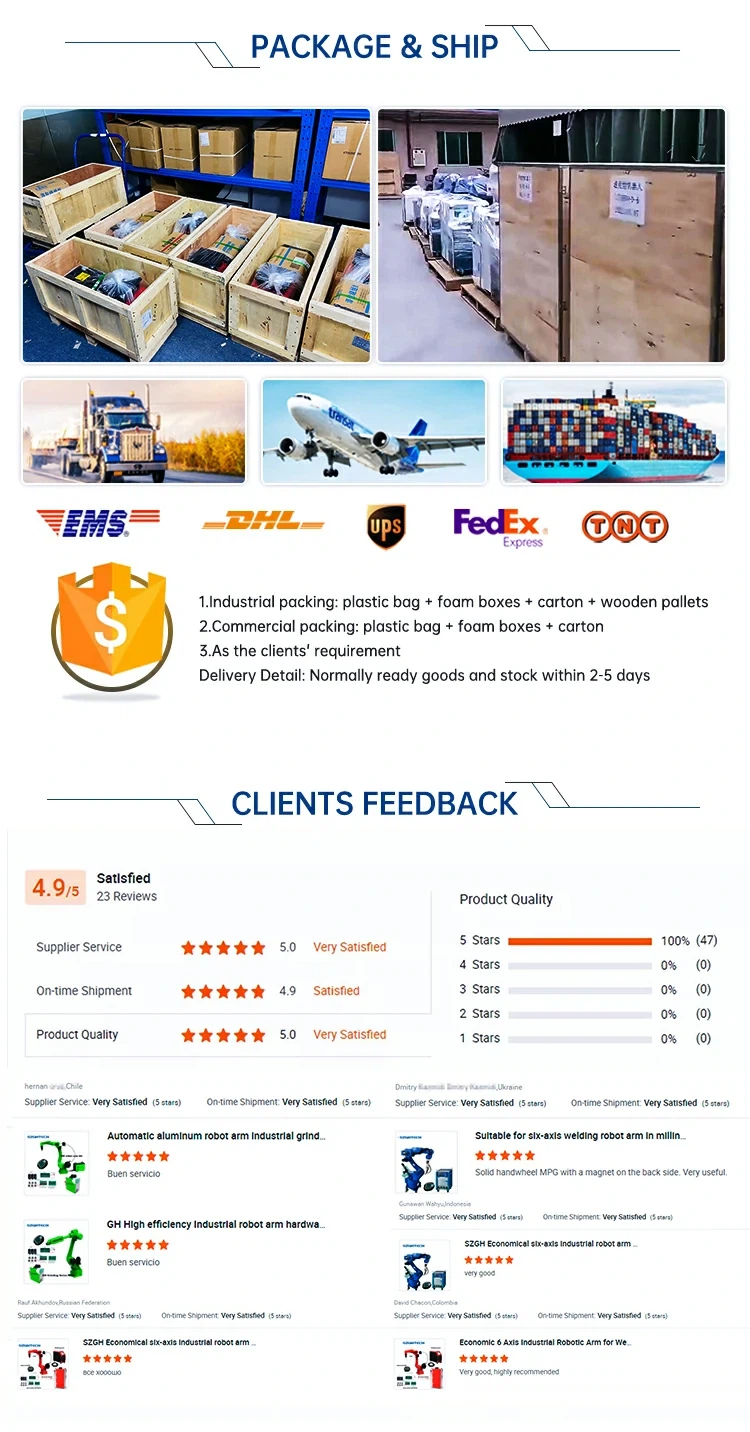

| Transport Package | Wooden Box |

| Certification | SGS Group,CE,ISO,RoHS |

| Mounting type | Ground, Bracket, Ceiling |

Special Service | 1. We can customize the standard color as you need! |

| Ultra Low Splash Fine control of the entire cycle from arc ignition droplet formation to liquid bridge opening for ultra-low spatter on short-circuit transitions. |

| Contact Retractionarc Starting New type contact retraction arc starting, reduce arcing splash and increase arcstarting power. | ![E_[L@2PCT{D67Y%0CX]N((B](/Content/uploads/2022748886/20221121181121dbceea5188ff4135b7707717a606a2de.png) |

| Constant Arc Length Control All sub-local speed inverter control, quickly adjust the arc voltage to achieve the stability of the welding procession & a wide arc voltage range. |

| Suitable for a variety of materials Built-in rich welding expert database, can realize the pulse and short circuit welding of carbon steel,stainless steel, aluminum alloy and other materials. |  |

Features:

1) Support for multi-language displays in Chinese, English, Russian, Korean, and Vietnamese; additional language options are constantly being developed.

2) Support up to 12-axis control, realizes the control of external axes (traveling axes and positioner).3) PLC software functions make logic control easier. Programming is made simple with process functions.

4) Structural optimization algorithm suitable for the body control of various types of structure.5) Suitable for multiple increments; absolute servo. Improved computer bus connection ensures reliability and practicability.

6) Open structure for synchronization of international technology and extension of functions. Industrial standards & reliable stability.

7) Modular setting of functions suitable for diverse applications. Safety module ensures safe production of the robots.

Q1: What is the length of your products' warranties? and post-purchase support?

A:Our warranty period is 12 months from the date of shipment, and our after-sales department will answer any queries you have in 24 hours. You can also get remote instruction via a PC network at any time.

Q2: How long does it take to deliver?

A: Typically, it takes 15 days to supply one set.

Q3: What is the duration of your guarantee?

A: Our goods come with a one-year warranty and lift-time technical assistance.

Q4: Do you make things or do you trade?

A: We are a Shenzhen, China-based manufacturer of automation robots.

Q5: What are your payment terms?

A: 100 percent previously. The Alibaba corporation will guarantee your payment if you pay using Trade Assurance through Alibaba. Regular customers could pay using L/C.

If you have any questions, pls feel free to contact me below.