Model | SZGH-H2100-B-6 |

| Payload | 6kg |

Reach | 2100mm |

Axes | 6-11 |

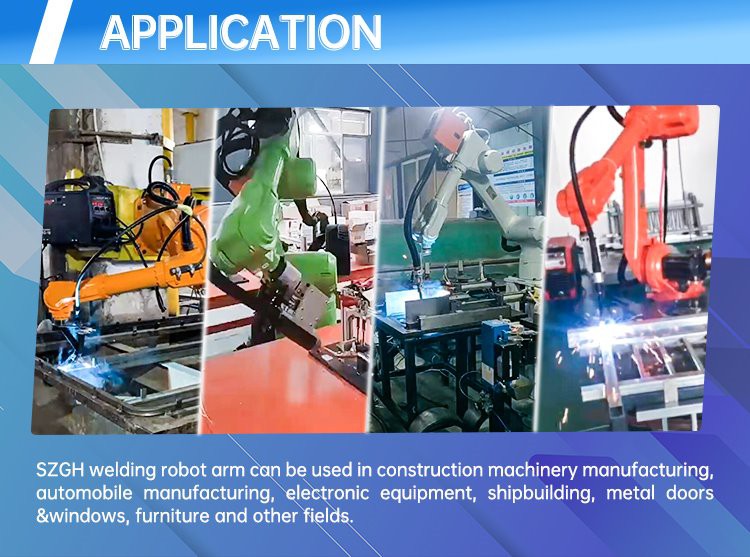

Application | welding |

| Atructure | Articulated |

Special Service | 1. We can customize the standard color as you need! |

After Warran | Video technical supports , Online supports |

| Packing list | |

| Robot body | 1 set |

| Robot teach Pendant | 1 set |

| Servo motor | 6 pcs |

| Servo driver | 6 pcs |

| RV gear box or Harmonic gear box | 6 pcs |

| Electrical cabinet | 1 pcs |

| Welding machine and torch gun | 1 set |

| Isolation transformer and wire feeding and other spare parts | 1 set |

1) Modular setting of functionssuitable for diverse applications. 8-axis control realizes the control of external axes (traveling axes and positioner).

2) Suitable for multiple increments; absolute servo.

Open structure for synchronization of international technology and extension of functions.

3) Software PLC functions facilitate logic control.

1. What information do you need to give me proper recommendation?

Answer: In order to recommend you the suitable machine model, please send us the detailed information regarding your product.Like material, thickness, welding position, minimum and maximum size of product, welding requirement, etc. It would be better if you could send us your product drawings. Then our engineer will recommend you the machine according to your welding requirement.

2. Can you provide customized service for our product?

Answer: Yes. We will provide you the professional robotic welding system solutions according to your specific product. Only you need to send us your detailed product drawings and welding requirement, then we will come out with the customized technical proposal for you.

3. What can you buy from us?

Answer: Industrial Robot Arms for welding, painting&spraying, handling materials/Pick and place, or grinding or other customized solution.

If you have any questions, pls feel free to contact me below.