Hot selling SZGH 6 axis Welding of ultra-heavy box structures robot arm

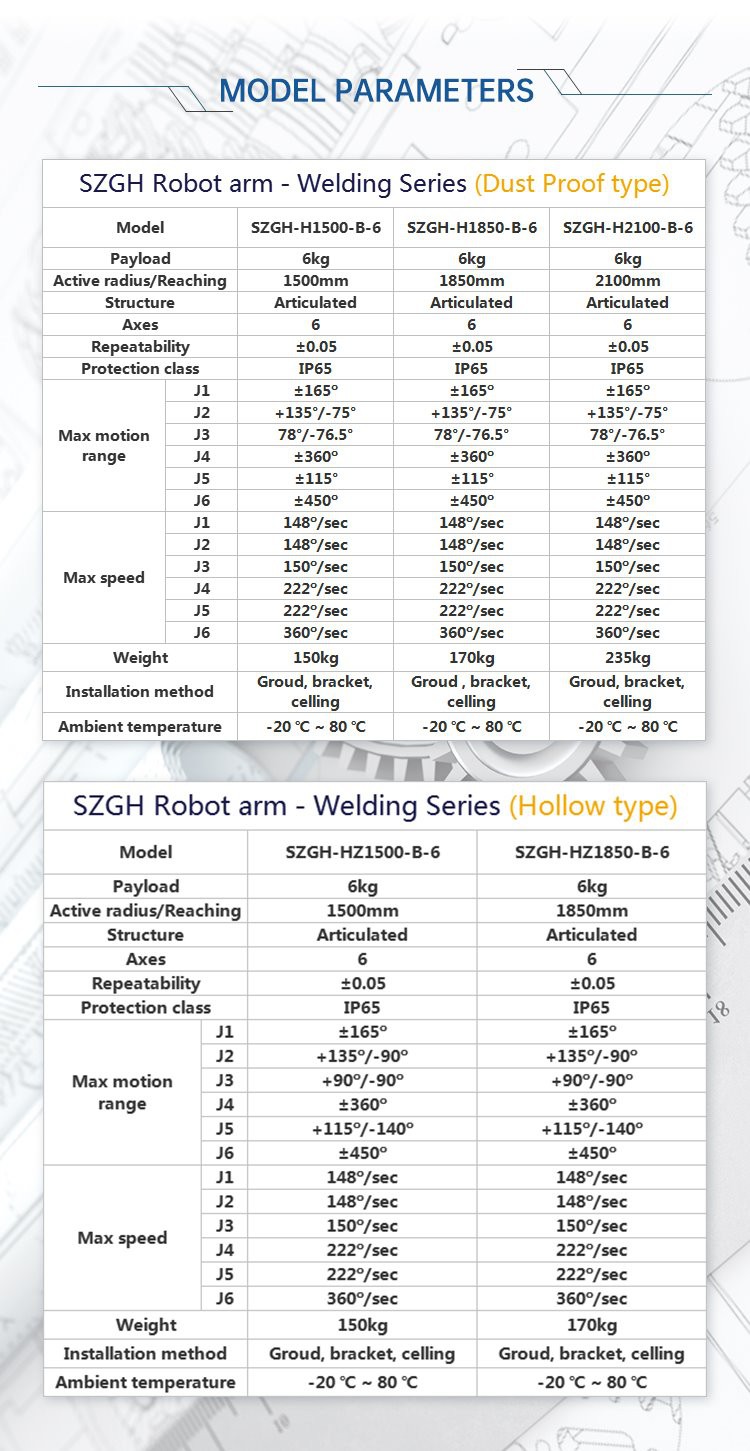

Model | SZGH-H1850-B-6 |

| Payload | 6kg |

Reach | 1850mm |

Axes | 6-11 Axes |

Application | welding |

Special Service | 1. We can customize the standard color as you need! |

After Warran | Video technical supports , Online supports |

| Packing list | Robot body ;Robot teach Pendant ;Servo motor ;Servo driver ;RV gear box or Harmonic gear box ;Electrical cabinet ;Welding machine and torch gun ;Isolation transformer and wire feeding and other spare parts |

1) Support up to 12axis control, realizes the control of external axes(traveling axes and positioner).

2) Structural optimization algorithm suitable for the body control of various types of structure.

3) Software PLC functions facilitate logic control. Process functions make programming easy.

| Storage | 2 GB |

| Safety module | The emergency and robot anomaly signals are linked to ensure rapid stop of the robot |

| Mode of operation | Teaching, representation, remote control |

| Mode of programming | Online teaching, process programming, teaching by dragging |

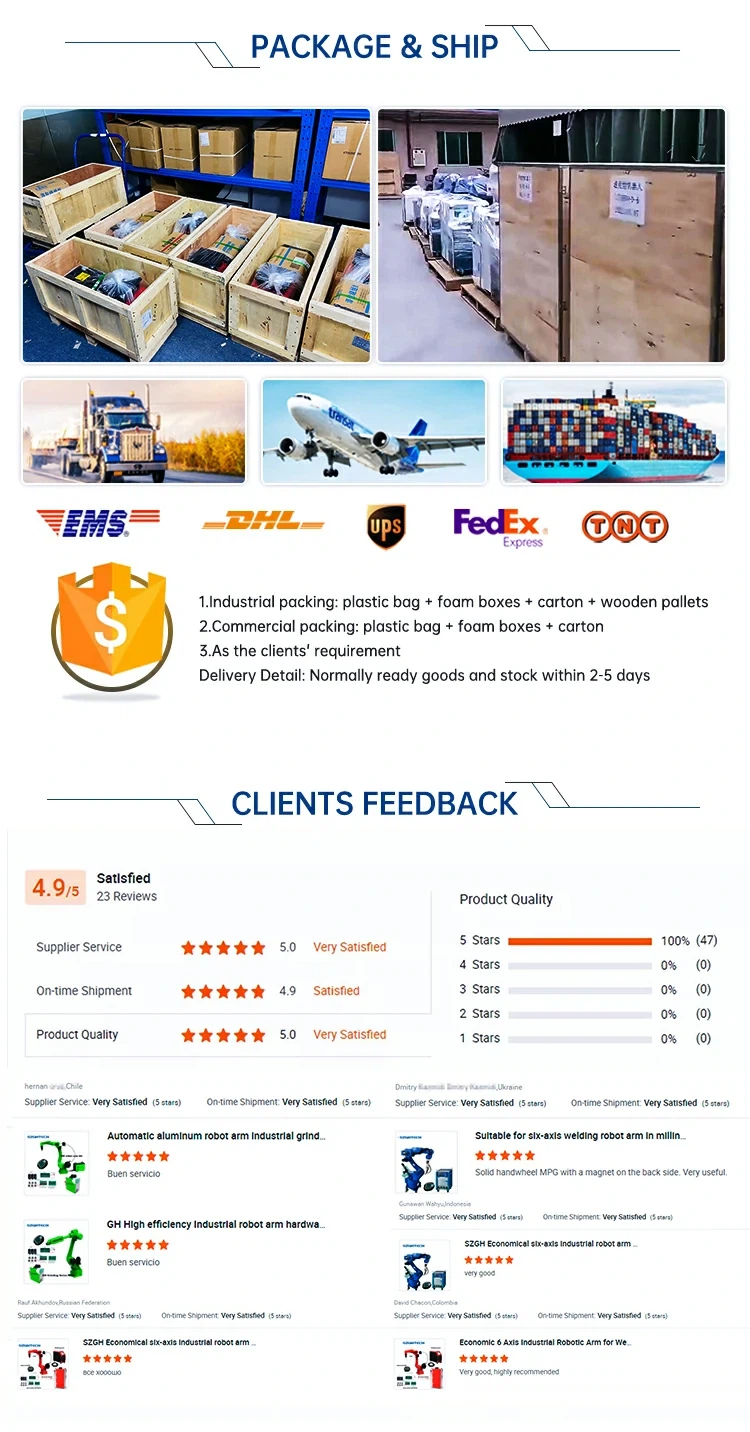

2). You can get good purchase experience and nice technical support;

3). We can provide customized design services quality guarantee, competitive quotation, and honest and reliable business is our tenet.

2. How can we guarantee the quality?

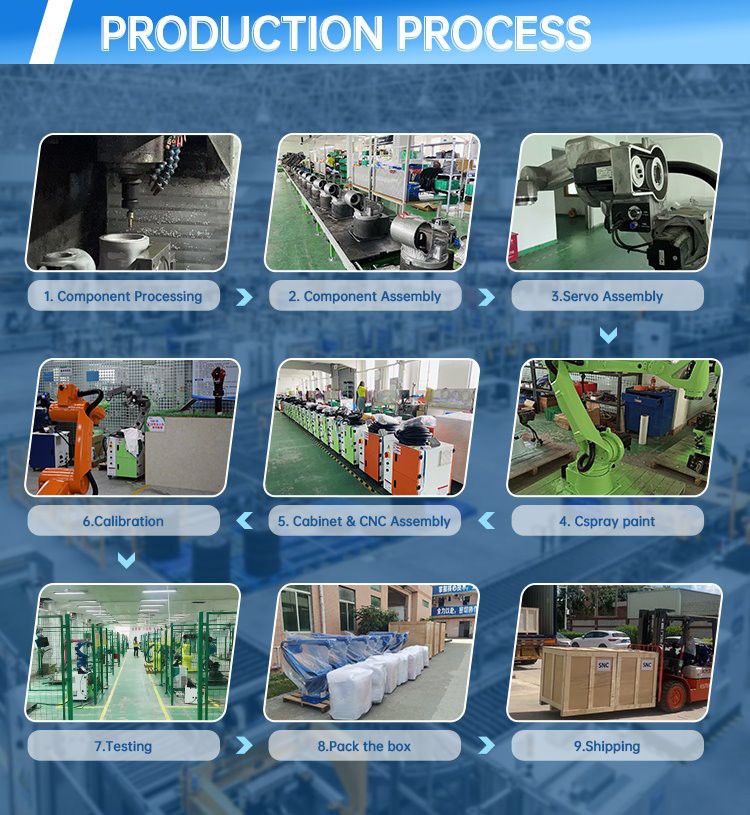

Always finishing a pre full testing by our professional engineers;

Always final 100% Inspection before shipment.

3. What can you buy from us?

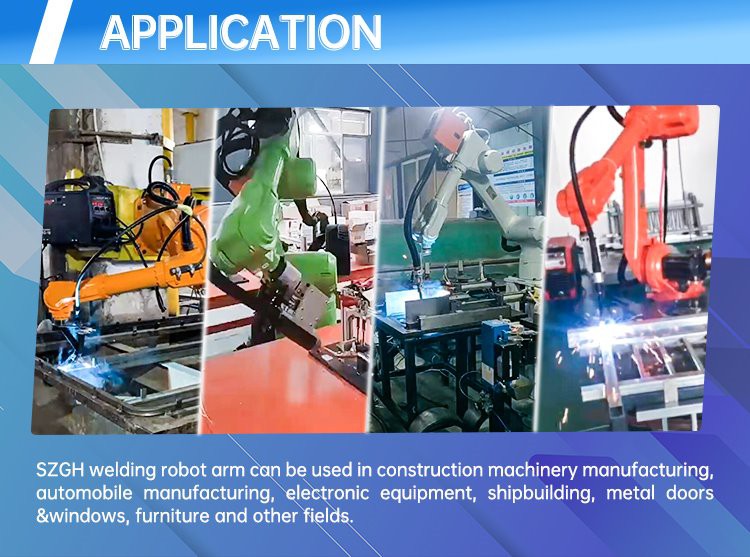

Industrial Robot Arms for welding, painting&spraying, handling materials/Pick and place, or grinding or other customized solution.

If you have any questions, pls feel free to contact me below.