Robot Arm 6 Axis Weld Industrial Welding Robotic Arm for Welding Aluminum alloy metal material

Model | SZGH-H1500-B-6 |

| Payload | 6kg |

Reach | 1500mm |

Axes | 6 |

Application | welding |

| Atructure | Articulated |

Special Service | 1. We can customize the standard color as you need! |

Application fields of welding robots

1. Automobile manufacturing: Welding robots are used for welding of automobile body, chassis, engine and other parts.

2. Electronics manufacturing: Soldering robots are used for the assembly and soldering of printed circuit boards (PCBs).

3. Construction: Welding robots are used for the welding of large steel structures, such as bridges, buildings and steel factory buildings.

4. Aerospace: Welding robots are used in the production and maintenance of aircraft, rockets, missiles and other aerospace components.

5. Military: Welding robots are used in the production and maintenance of military equipment, such as tanks, fighter jets, etc.

6. Medical devices: Welding robots are used in the production of medical devices, such as surgical instruments, medical equipment, etc.

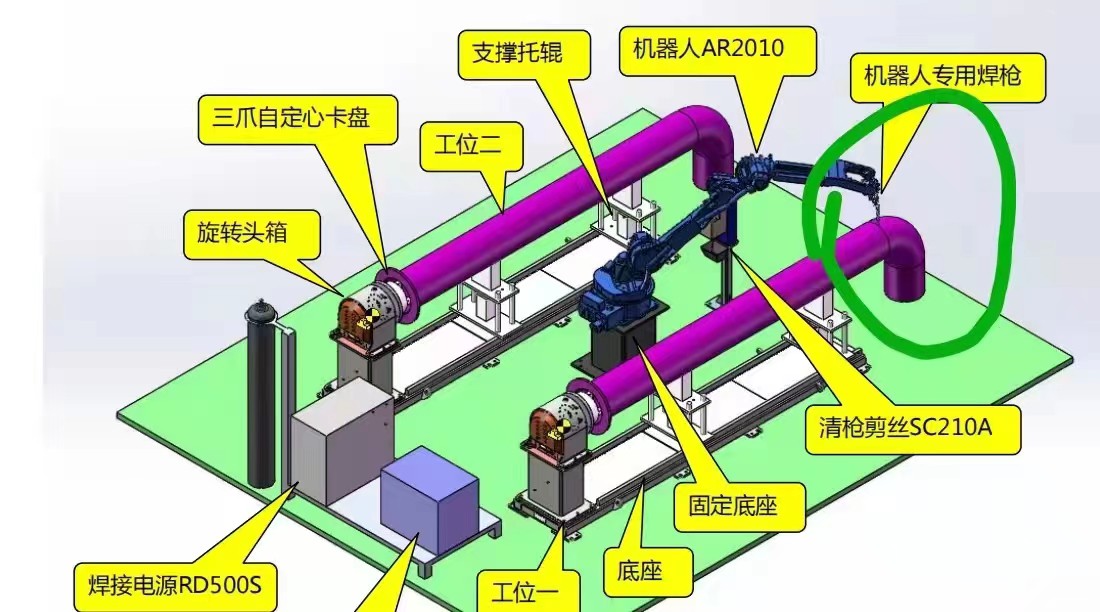

Solutions for welding round pipes

Solution one:

Solution two:

A: Guide rail of product turning seat

B: Center bracket A

C: Center Bracket B

D: The product turns over the machine head

E: Welding robot ground rail

F: welding robot

![9ZCT]G54NBE]MO(MMYA}$}F](/Content/uploads/2023748886/202303081513538136ebc034af41e98c8d04b490486d0a.png)

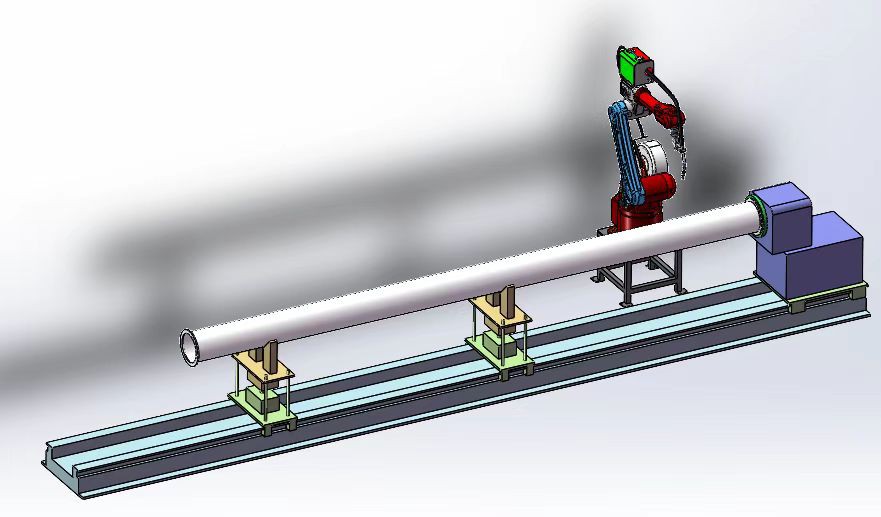

Solution three:

A: Guide rail of product turning seat

B: Center bracket A

C: Center Bracket B

D: The product turns over the machine head

E: welding robot

Product Advantages

As a professional robot manufacturer, we are well aware of the importance customers place on the cost and quality of robots. Therefore, we are committed to providing customers with the best price as well as high-quality welding robots to meet your needs.

First of all, we have to make it clear that the cost of a robot is not only the price of the robot itself, but also its operation and maintenance costs. Our welding robots use the most advanced technology and materials to ensure their efficient and stable operation and reduce your operating costs. At the same time, we provide a professional after-sales service team to ensure that your robot is maintained and supported in time during use, reducing your maintenance costs.

Secondly, our welding robot adopts an intelligent control system, which can automatically adjust and optimize according to your welding needs to improve production efficiency and product quality. At the same time, we also provide flexible robot programming solutions, which can be quickly customized and adapted according to your needs, reducing your labor costs.

Finally, our welding robots use high-quality materials and workmanship to ensure their long-term stable operation and service life, bringing you a long-term return on investment. We also offer a variety of options, offering different robot models and configurations based on your needs and budget, so you can choose the one that works best for you.

To sum up, our welding robots are characterized by high quality, high efficiency, flexibility, reliability and long life. We believe that these advantages will attract you to purchase and use our robots. We look forward to cooperating with you and providing you with the best products and services.

If you have any questions or have any need, pls feel free to contact me below. We will reply you warmly.