Robot Arm 6 Axis High Quality Robotic Welding Arm For Bicycle Frame

Product Description

SZGH-H1500-B-6 robot is dedicated to welding robot ; easy operation, high efficiency and safety;

SZGH company has 25 models robot arm in mass production: including general purpose, welding, spraying, palletizing, grinding and handling types. All models are equipped with an intelligent robot control system which independently developed by us.

We also add other components to the sixaxis robots, and customize nonstandard robotic solution as customer needs

Currently, 9-axis linkage robots are also mass-produced and sold.

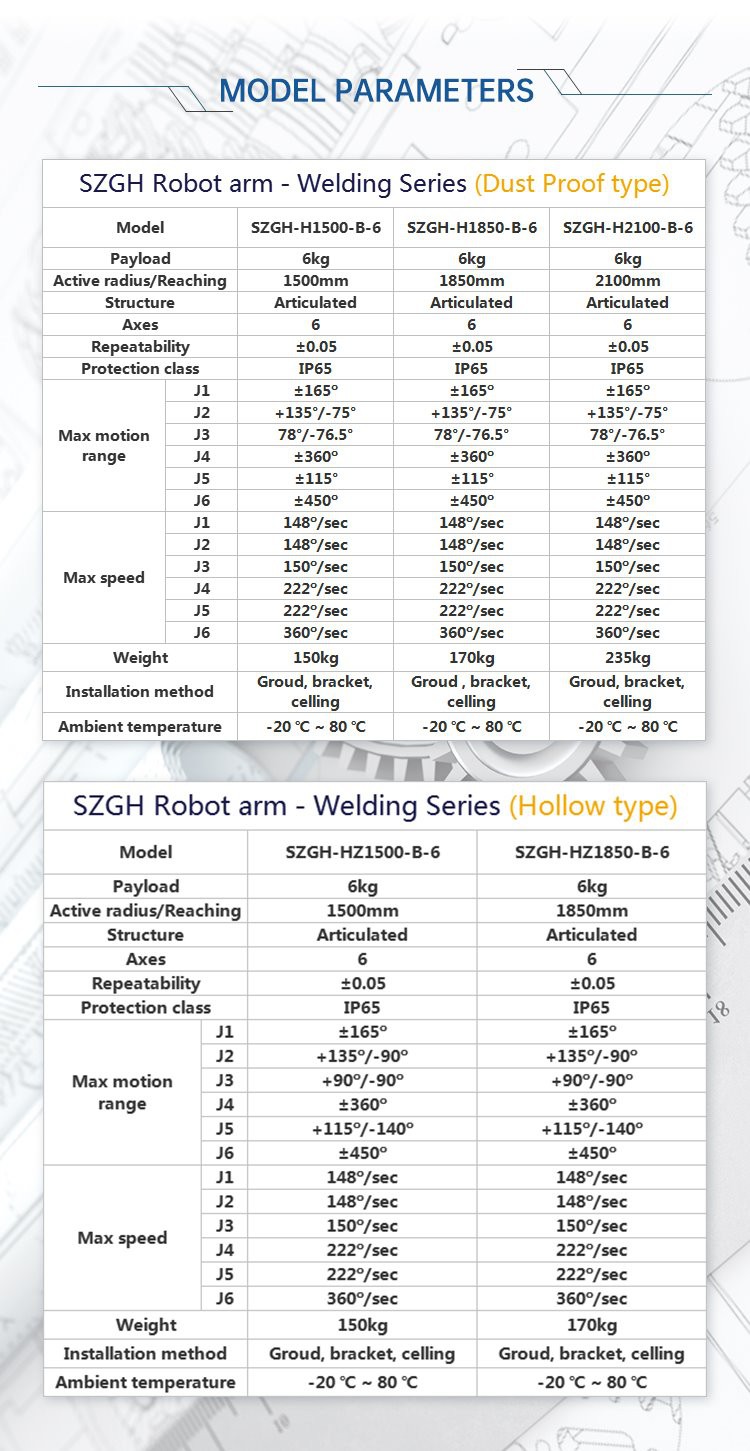

Model | SZGH-H1500-B-6 |

| Payload | 6kg |

Reach | 1500mm |

Axes | 6 |

Application | welding |

Video Factory Inspection | Provide |

Transport Package | Wooden box |

| Certification | SGS Group,ISO,CE,RoHS |

Place of Origin | Shenzhen City,Guangdong Province,China. |

| Atructure | Articulated |

Special Service | 1. We can customize the standard color as you need! |

| Ultra Low Splash Fine control of the entire cycle from arc ignition droplet formation to liquid bridge opening for ultra-low spatter on short-circuit transitions. |

| Contact Retractionarc Starting New type contact retraction arc starting, reduce arcing splash and increase arcstarting power. | ![E_[L@2PCT{D67Y%0CX]N((B](/Content/uploads/2022748886/2022112210460630236c3d91fa4a8da422404acf4d6ffe.png) |

| Constant Arc Length Control All sub-local speed inverter control, quickly adjust the arc voltage to achieve the stability of the welding procession & a wide arc voltage range. |

| Suitable for a variety of materials Built-in rich welding expert database, can realize the pulse and short circuit welding of carbon steel,stainless steel, aluminum alloy and other materials. |  |

Features:

1) Chinese, English, Russian, Korean, and Vietnamese multi-language displays are supported; new language options are continually being developed.

2) Support up to 12-axis control, realizes the control of external axes (traveling axes and positioner).

3) Structural optimization algorithm suitable for the body control of various types of structure.

4) Open structure for synchronization of international technology and extension of functions. Industrial standards & reliable stability.

5) Software PLC functions facilitate logic control. Process functions make programming easy.

6) Modular setting of functions suitable for diverse applications. Safety module ensures safe production of the robots.

7) Suitable for multiple increments; absolute servo. Improved computer bus connection ensures reliability and practicability.

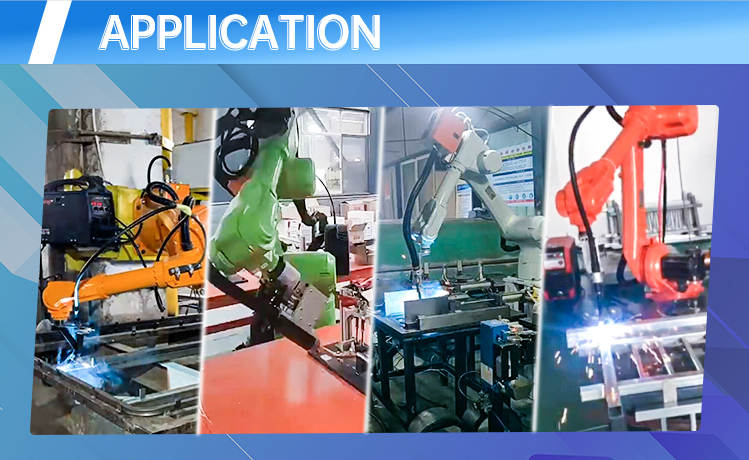

Main Applications:

SZGH welding robot arm can be used in construction machinery manufacturing, engineering machinery, mining machinery, locomotives, electrical appliances, furniture , automobile manufacturing, electronic equipment, shipbuilding, metal doors &windows, furniture and other industries.

Such as:robotic welding arm for bicycle frame.

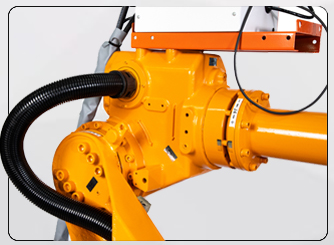

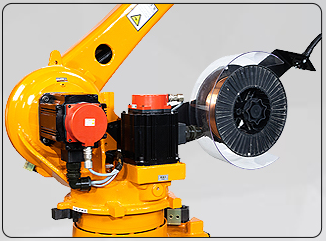

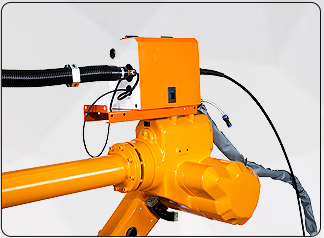

Welding station with a positioner SZGH-H1500-B-6 robot is dedicated to welding. It is a robot developed for more adverse field environment of the customers based on the existing LH1850-B-6 robot. Compared with the previous model, this product has a higher floor space and stabler construction; moreover, there is a fully enclosed axis to effectively prevent welding spatters from damaging cables of the robot. | ![)XIUTIU5]SQM68DIAW63O(1](/Content/uploads/2022748886/202211221109435b71c5da830b4275a9e59866bcd4470d.png) |

Shenzhen Guanhong Technology CO.,LTD(Built in 19 November 2010) is one of the leading CNC & automatic company in China, specialized in designing projects, marketing, and oversea trading, having extensive experience in CNC package solution, Our focus has been on providing the high quality of Industrial Robot Arm, cnc controller, servo motor and driver, spindle motor and driver.

We has professional technical team, strictly product test for high quality guarantee, very competitive quotation, specially we has flexible and convenient payment mode and low cost delivery solution for clients.

Our company tenet "Quality is the life of enterprise ", your satisfy is our greatest achievement.

OUR SERVICE

①CERTIFIED ACTUAL PRODUCTS

We have a zero-tolerance policy for asset recovery vendors.

②LOWEST PACKAGE PRICES

Always offer lower price than other companies.

③PROFESSIONAL TECHNICAL ENGINEER TEAM

Possible fastest response and support to client application demand.

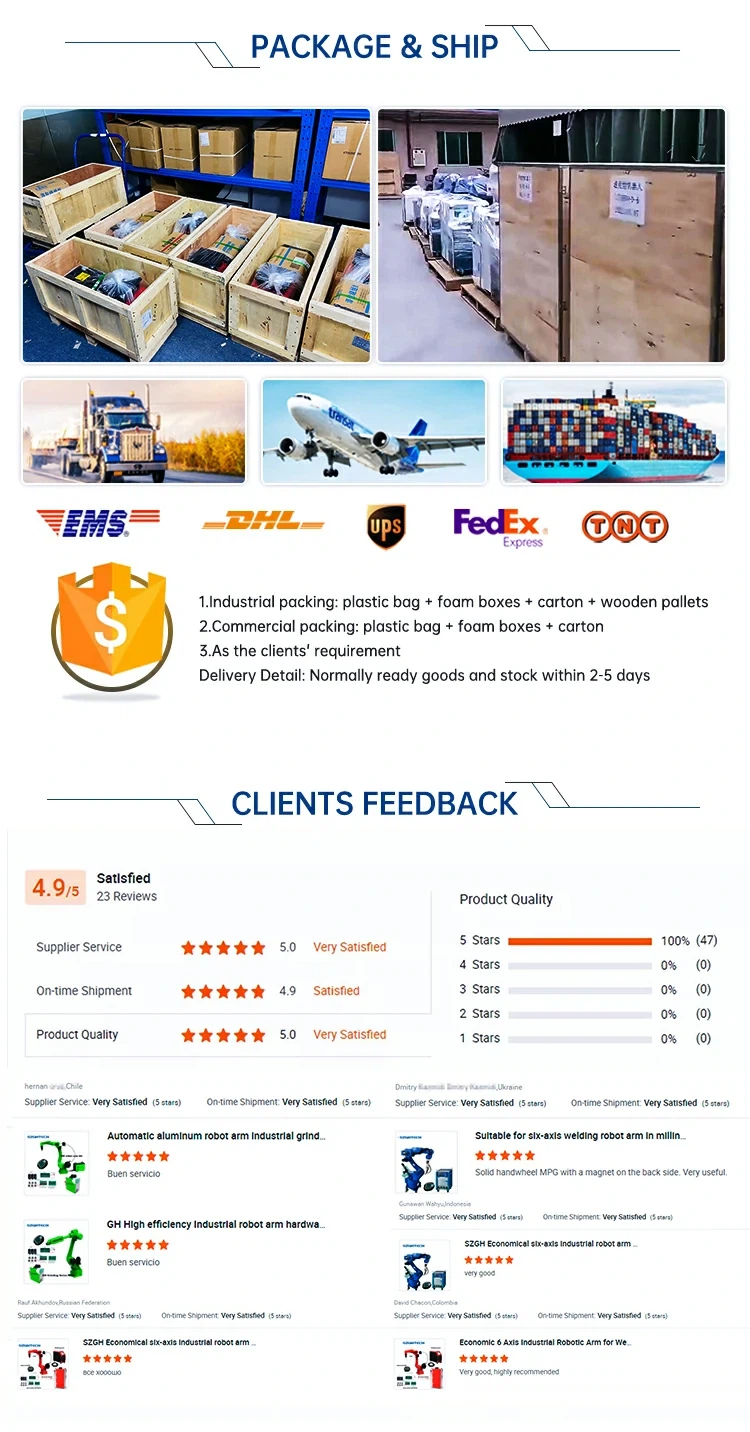

④FAST, PROFESSIONAL AND RELIABLE INTERNATIONAL DEL IVERY

Flexible and low cost delivery solution for clients.

⑤QUALITY GUARANTEE

Free, one-years warranty and life -long maintenance. Any quality problem, GuanHong promise to refund.

Q: Are you a factory?

A: Yes,we are factory,have more than 10 years experience;

Q: What is your MOQ?

A: Our current MOQ is one set.

Q: How long is the delivery time?

A: In general, the delivery time is 15 days for 1 set.

Q: What is your guarantee term?

A: The warranty period for our products is one year along with lift time technical support.

Q: Are you a manufacturer or a trading firm?

A: We are a robotic automation manufacturer in Shenzhen, China.

If you have any questions, pls feel free to contact me below.