SZGH-H1500-B-6

The 1500mm welding robot has high efficiency, high precision, high reliability and safety, and is suitable for most welding tasks on industrial production lines, which can improve production efficiency and quality.

Technical specifications

| Load capacity | 6 kg, which is suitable for most welding tasks and workpiece sizes. |

| Accuracy | Repetitive positioning accuracy of the robot is ±0.05mm, which has high precision and reliability, and can ensure the consistency and repeatability of the welding process. |

| Control system | Adopts a high-performance controller, which can realize high-speed and high-precision motion control, and can communicate with other devices through external interfaces. |

| Welding gun | Be equipped with a MIG welding gun, which can be welded using metal inert gas welding technology. The welding torch can be rotated, bent and adjusted to meet different welding needs. |

| Safety | Has multiple safety protection measures, such as anti-collision sensors and emergency stop buttons, which can ensure that the robot will not cause danger to people or equipment during operation. |

| Stability | The structure of this robot is stable and can maintain precise movement and welding under high load. Its design takes into account the center of gravity and motion characteristics of the robot, which can ensure the stability and accuracy of the robot during operation. |

| Programming | The robot can be programmed using a GUI-based programming software or integrated into the production line control system using an external program. |

Robot Kit Contents

1.robot arm

The robot arm is the core component of the whole system and is responsible for completing the welding work. The arm length of 1500mm can cover most welding application scenarios, and can also be customized according to specific needs. The robotic arm is equipped with multiple degrees of freedom, enabling complex welding actions.

2. Controller

The controller is the "brain" of the robot arm, which can realize functions such as arm motion control, precise position adjustment and welding parameter control. Through the controller, the high-precision and high-efficiency movement of the robot arm and the optimization of the welding process can be realized.

3.Welding gun

The welding gun is the end tool of the robot arm, which is used to weld the workpiece. Welding guns can be customized according to different welding needs, including welding gun shape, material, electrode tip and wire diameter, etc. The quality and precision of the welding gun directly affect the welding quality and efficiency.

4.Sensor

The sensor can realize real-time measurement and feedback of the robot arm and the workpiece, helping the robot arm to achieve more precise motion and welding process control. Sensors may include photoelectric sensors, contact sensors, force sensors, and the like.

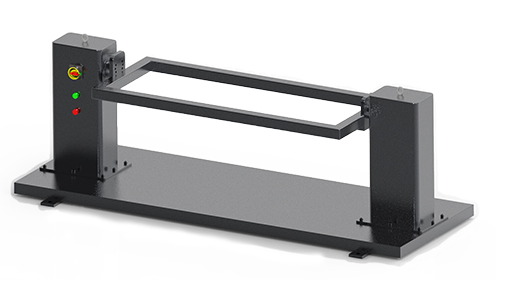

5.Track system

The track system can provide a stable motion track for the robot arm, and can also expand the range of motion of the arm. The material and structure of the track system can be customized according to the specific application.

6. Safety system

The safety system can ensure the safety of the robot arm during movement and welding. Safety systems can include light barriers, safety gates, emergency stop buttons, and more.

7. Data analysis system

The data analysis system can monitor and analyze the robot arm and welding process in real time, helping users optimize the production process, improve efficiency and reduce costs.

Applicable environment

1. Conveyor belt and material rack: In order to realize the automated production process, it is necessary to match the welding robot with automatic equipment such as conveyor belt and material rack. This enables the automatic delivery of workpieces to the working area of the robot and automatic collection of welded workpieces. This matching method can greatly improve production efficiency and quality.

2. Workpiece Positioner: In some applications, a workpiece positioner is required to ensure the position and angle of the welded workpiece. Matching a 1500mm welding robot with a workpiece positioner allows for greater welding accuracy and stability while reducing the need for manual intervention.

![]()

If you have any questions or you have any need, pls feel free to contact me below. We will reply you warmly.