SZGH-H1500-B-6

Product Description

The most popular model of SZGH welding robot arm is SZGH-H1500-B-6 , the kits with 6 joints, works with EtherCAT drivers, can realize full automatical welding. With 1500mm reach and payload 6kg, Robot arm is composed with teach pendant, control cabinet, MIG350A welding machine, wire feeder etc,also can support Chinese, English, Russian and Vietnamese. The usage of robot arm to factory will highly increase the production efficiency and reduce the rejection rates, it will definitely make more profits to our user.

Main Applications

Automobile

Metal doors &windows

Engineering Machinery

Mining Machinery

Locomotives

Electrical Appliances

Furniture and Other industries

| Payload | 6KG | |

| Reach | 1500mm | |

| Structure | Articulated | |

| Number of axes | 6 | |

| Repeatability | ±0.05mm | |

| Max motion range | Axis 1 | ±165° |

| Axis 2 | +135°/-70° | |

| Axis 3 | +85°/-85° | |

| Axis 4 | ±150° | |

| Axis 5 | +30°/-240° | |

| Axis 6 | 土360° | |

| Max speed | Axis 1 | 148°/sec |

| Axis 2 | 148°/sec | |

| Axis 3 | 148°/sec | |

| Axis 4 | 222°/sec | |

| Axis 5 | 222°/sec | |

| Axis 6 | 360°/sec | |

| Weight | ~150kg | |

| Mounting type | Ground, bracket, ceiling | |

| Ambient temperature | 5℃~45℃ | |

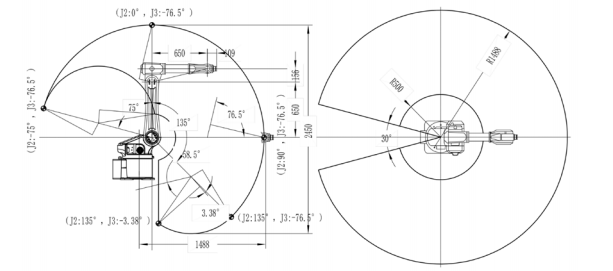

Robot Motion Range

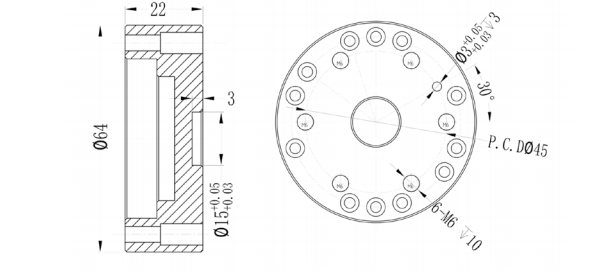

Robot Flange Connection

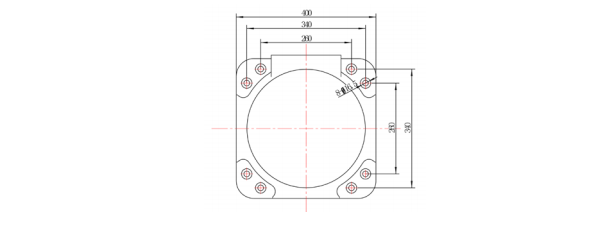

Robot Base Installation

Characteristics of 1500mm Welding Robot Arm

1. Moderate arm span: The 1500mm welding robot has a moderate arm span and can adapt to different welding work, which can complete the welding of small parts and the welding of large workpieces.

2. High precision: The welding robot adopts high-precision sensors and control systems, which can achieve high-precision motion and welding, and at the same time, it can automatically adjust welding parameters to ensure welding quality.

3. High efficiency: 1500mm welding robot can be programmed to achieve a variety of welding methods, suitable for various welding processes, and can efficiently complete welding tasks and improve production efficiency.

4. Safety: Welding robots are machine-controlled and can work in hazardous environments, reducing the risk of injury to operators, while also being able to achieve safety protection through safety sensors.

Application of 1500mm Welding Robot Arm

1. Machinery manufacturing industry: In the machinery manufacturing industry, 1500mm welding robots can be used to weld various mechanical parts, such as gears, bearings, reducers, etc. In addition, due to its high precision and high efficiency, it can also be used to weld complex mechanical structures, such as automobile chassis, lifting mechanisms, etc.

2. Metal processing industry: In the metal processing industry, 1500mm welding robots can be used to weld different kinds of metal materials, such as iron, copper, aluminum, etc., as well as metal components of various shapes, such as plates, pipes, profiles, etc.

3. Electronic manufacturing: In the electronics manufacturing industry, 1500mm welding robots can be used to weld various electronic components and electronic products, such as mobile phones, flat plates.

4. Food processing industry: In the food processing industry, 1500mm welding robots can be used to weld various stainless steel products, such as food production equipment, stoves.

In summary, 1500mm welding robot has the characteristics of moderate reach, high precision, high efficiency and safety, and is widely used in machinery manufacturing, metal processing, electronic manufacturing, and food processing.

If you have any questions and have any need, pls feel free to contact me below, in this way ,we can help you better from us, and we will reply you warmly.