The Latest Catalog Of The Robotic Manipulator Arm Has Been Attached Below,Pls Kindly to check it.

Product Description

SZGH-T1500-C-6 is our General-purpose Series Robotic Manipulator Arm,can be do 750mm-2950mm reaching ;widely used for Materials handling, parts transfer, machine management, testing, gluing, &assembly ; with favorable price, wide application, safe and efficient, is a product worth having. It is a light-weight body with a suitable arm length and a moderate load weight, reaching out to customers.

Product parameters

| Model | Payload | Axes | Mounting Type | Specification |

| SZGH-T1500-C-6 | 10KG | 6-11 Axes | Ground,Bracket,Ceiling | Video Factory Inspection |

| Reaching | Structure | Weight | Transport Package | Trademark |

| 1500mm | Articulated | 150KG+70KG | Wooden Box | SZGH |

| HS Code | Origin | Repeatability | Ambient Temperature | Production Capacity |

| 8479509090 | Shenzhen | ±0.05mm | -20°C~80°C | 1000 Sets/Month |

Specifications and prices of general-purpose robots:

Our general-purpose robotic manipulator arms can generally be used in welding, handling, spraying, grinding, loading and unloading, etc. If you have any needs about industrial robots, please contact us for more details.

Our general-purpose robotic manipulator arm has two hot-selling models:

The small model is SZGH-T750-B-6, which is suitable for school projects and experiments, etc. The general price is: $6580.

The medium-sized model is: SZGH-T1500-C-6, which is suitable for spraying, handling, small cutting, grinding, etc. The general price is $8460.

Note:The price is for reference only. The price will change with the exchange rate of the US dollar and the company's promotional festivals, performance competitions, etc.

For more accurate prices, please consult again, and the prices at that time shall prevail.

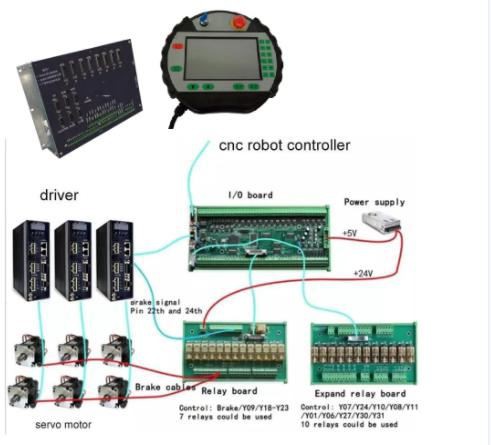

Robot controller systems

1)Structural optimization algorithm suitable for the body control of various types of structure.

2)Modular setting of functionssuitable for diverse applications. 8-axis control realizes the control of external axes (traveling axes and positioner).

3)Suitable for multiple increments; absolute servo.

Open structure for synchronization of international technology and extension of functions.

4)Software PLC functions facilitate logic control.

Process functions make programming easy.

5)Improved computer bus connection ensures reliability and practicability.

6)Safety module ensures safe production of the robots.

7)The teaching pendant with touch screen is easy to operate and easy to use.

Industrial standards &reliable stability.

Technical Teatures

The general-purpose robot is a highly flexible and multi-functional automation equipment that can adapt to the needs of various production scenarios, including assembly, handling, spraying, welding and other applications.

High flexibility: Universal robots can adapt to many different application scenarios, have good flexibility and adaptability, and can quickly respond to different production needs.

High-precision positioning: The robot uses high-precision sensors and control systems to achieve precise positioning and operation, ensuring production efficiency and product quality.

High-speed movement: The robot can realize high-speed movement, greatly improving production efficiency and response speed.

Safety and reliability: The robot adopts a multi-layer safety protection system, which has good safety and reliability, and can guarantee the safety of human-machine cooperation.

Easy to program: The robot has a simple and easy-to-use programming interface, which can quickly realize programming and control in different application scenarios.

Pls feel free to let us know your needs and concerns so that we can better assist you .Look forward to a long and fruitful partnership.