SZGH-B1850-3C-4

Product lntroduction

Payload | 30kg |

| Structure | Articulated |

Axes | 4 |

| Reach | 1850mm |

| Weight | 230kg |

Application | Materials handling, parts transfer, palletizing, deburring &cutting |

Special Service | 1. We can customize the standard color as you need! |

Main Applications

Materials Handling, Parts transmission, Stacking, Deburring, Cutting

The five major fields where handling robots are widely used are: automobile industry, electronics industry, rubber and plastic industry, metal products industry, and food industry, mainly engaged in sorting, handling and palletizing.

Loading and unloading on the assembly line SZGH-B1850-3C-4 robot has a load of 30kg, which can be used for loading and unloading of a single press, or for loading and unloading of multiple presses to realize the assembly line stamping operation.The picture on the right shows our company providing an assembly line stacking solution for a customer. The size of the customer's card is 1.1m × 1.1m, the required stacking height is 1.6m, and one robot can stack two pallets at the same time, greatly improving the efficiency of flow production and saving labor. |

|

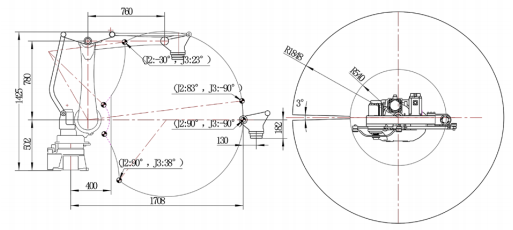

Dimension drawing

Robot Motion Range

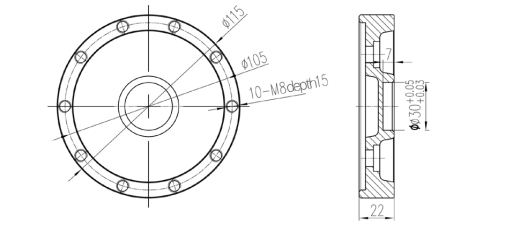

Robot Flange Connection

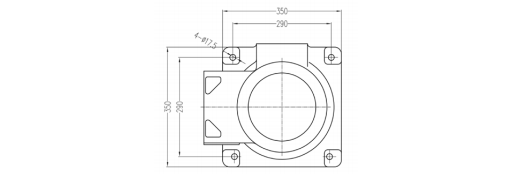

Robot Base Installation

Safety hazards and precautions

Collision risk: Since the 1850mm handling robot usually has a large size and a strong load capacity, it may collide with people or objects during driving. In order to avoid such accidents, it is necessary to isolate the range of motion of the robot, and at the same time install safety sensors and alarm devices around it.

Power system safety: The battery or cable power supply system of the robot needs to be checked and maintained frequently to ensure its normal operation and avoid dangerous events such as fire or electric shock.

Control system security: The control system of the robot needs to set strict permissions and passwords to prevent unauthorized personnel from manipulating the robot. In addition, the robot's software and security patches need to be updated frequently to ensure its safety and reliability.

Operator training: Operators who use robots need to receive professional training and guidance to understand the operating principles and safe operating procedures of robots to ensure their correct operation and avoid misoperation.

Maintenance: The maintenance of the robot needs to be carried out in accordance with the requirements of the manufacturer, including cleaning, lubrication, inspection and replacement of wearing parts, etc., to ensure the long-term stable operation of the robot.

If you have another question or you have any need, pls feel free to contact us as below. We will reply you enthusiastically.