SZGH-P1950-B-6

Product Description

Axes | 6-11 Axes |

| Payload | 6KG |

Application | Parnting and spraying |

Special Service | 1. We can customize the standard color as you need! |

After Warran | Video technical supports , Online supports |

| Reach | 1950mm |

| Mounting Type | Ground, bracket ,ceiling |

The 1950mm industrial spraying robot is a high-performance automation equipment that can be widely used in various spraying scenarios, such as automobile manufacturing, machinery manufacturing, architectural decoration and other fields. The robot has the following functions:

1. Precise spraying: The robot is equipped with high-precision sensors and control systems, which can achieve precise spraying and ensure coating quality and efficiency.

2. Automated operation: The robot has the ability to operate automatically, which can replace manual spraying operations to improve production efficiency and reduce costs.

3. High reliability: The robot uses high-quality materials and components, which have good corrosion resistance and durability, ensuring long-term stable operation of the machine.

4. Flexible adjustability: The robot can be adjusted and customized according to different spraying requirements, including spraying angle, spraying speed, spraying volume and other parameters.

Case Studies

An automobile manufacturing company needs to carry out a large number of spraying operations on automobile bodies. Traditional manual spraying requires a lot of manpower input, which is inefficient and prone to problems such as uneven coating. In order to improve production efficiency and quality, the company decided to use a 1950mm industrial spraying robot for automatic spraying.

After using the robot, the company found that the spraying efficiency has increased by nearly 3 times, and the coating quality has also been significantly improved. At the same time, the speed and angle of robot spraying can be precisely controlled, which not only reduces the cost of spraying, but also improves the overall appearance quality of the product. Therefore, the company decided to purchase multiple 1950mm industrial spraying robots for production in order to improve production efficiency and product quality.

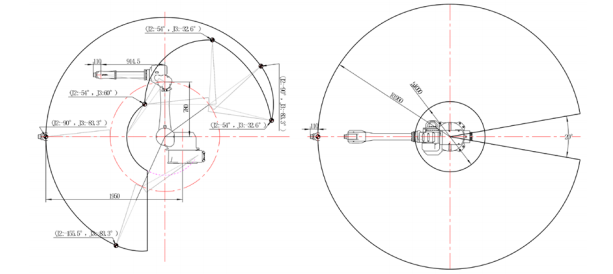

Robot Motion Range

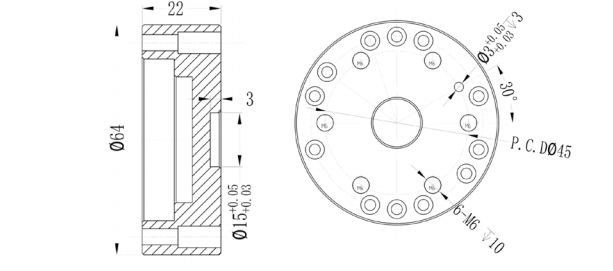

Robot Flange Connection

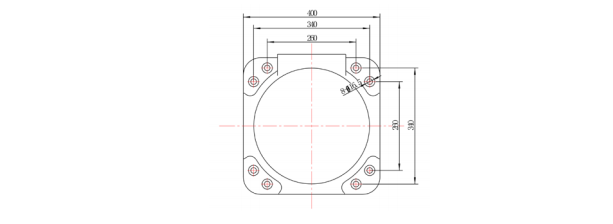

Robot Base Installation

If you have any questions or you have any need, please feel free to contact me.We will reply you warmly.