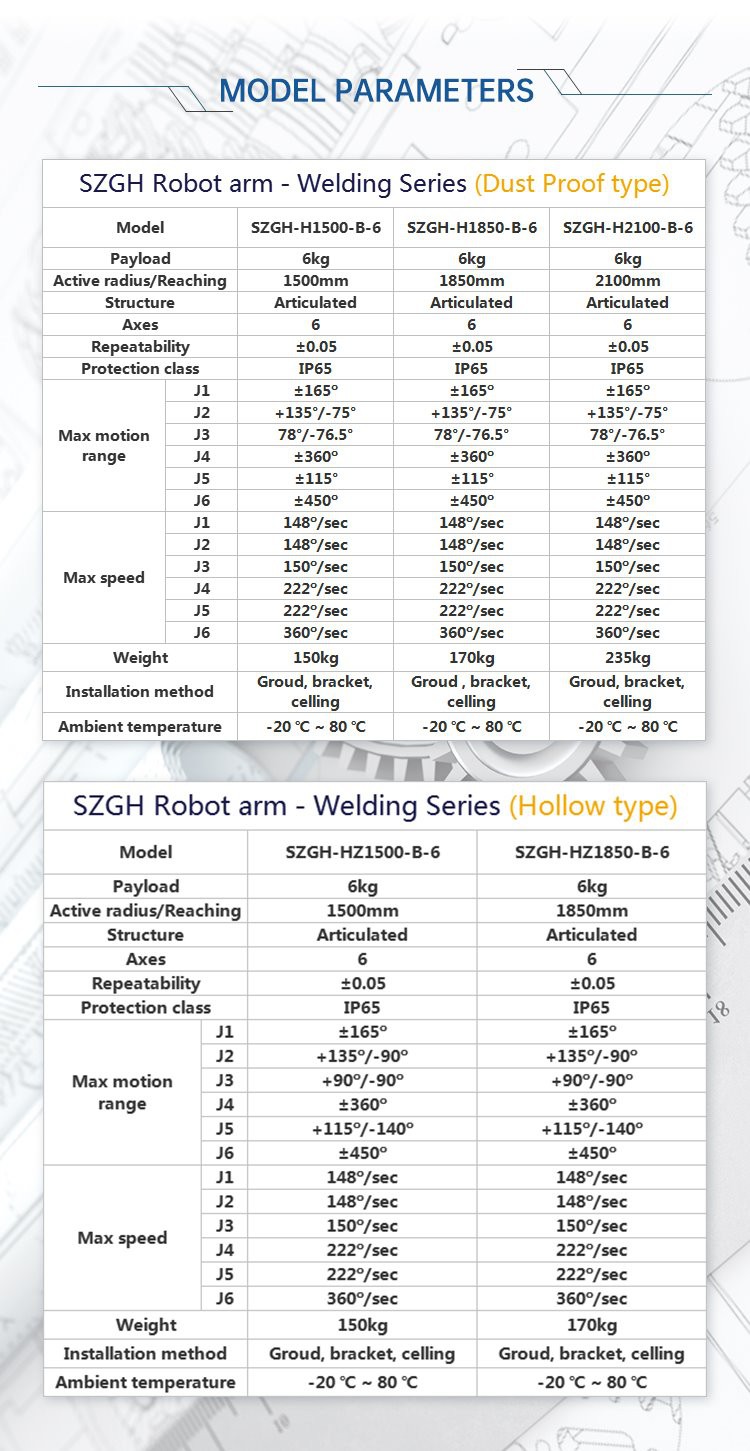

Model | SZGH-H1850-B-6 |

| Payload | 6kg |

Reach | 1850mm |

Axes | 6-11 Axes |

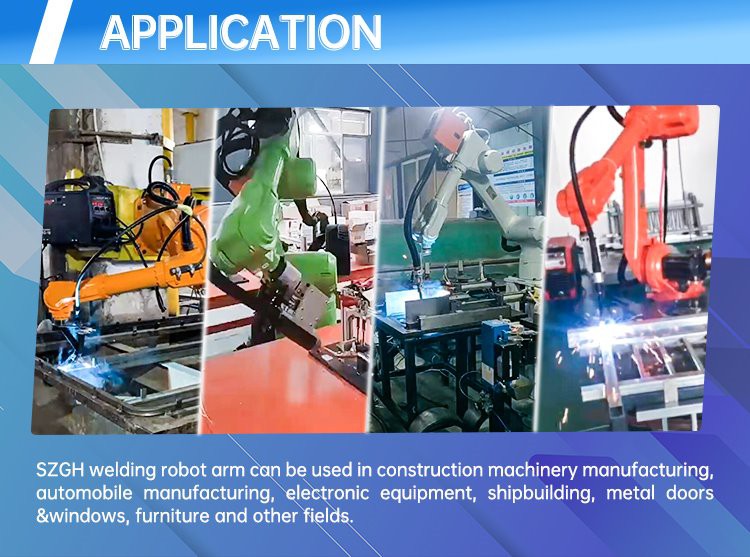

Application | welding |

Special Service | 1. We can customize the standard color as you need! |

After Warran | Video technical supports , Online supports |

| Packing list | Robot body ;Robot teach Pendant ;Servo motor ;Servo driver ;RV gear box or Harmonic gear box ;Electrical cabinet ;Welding machine and torch gun ;Isolation transformer and wire feeding and other spare parts |

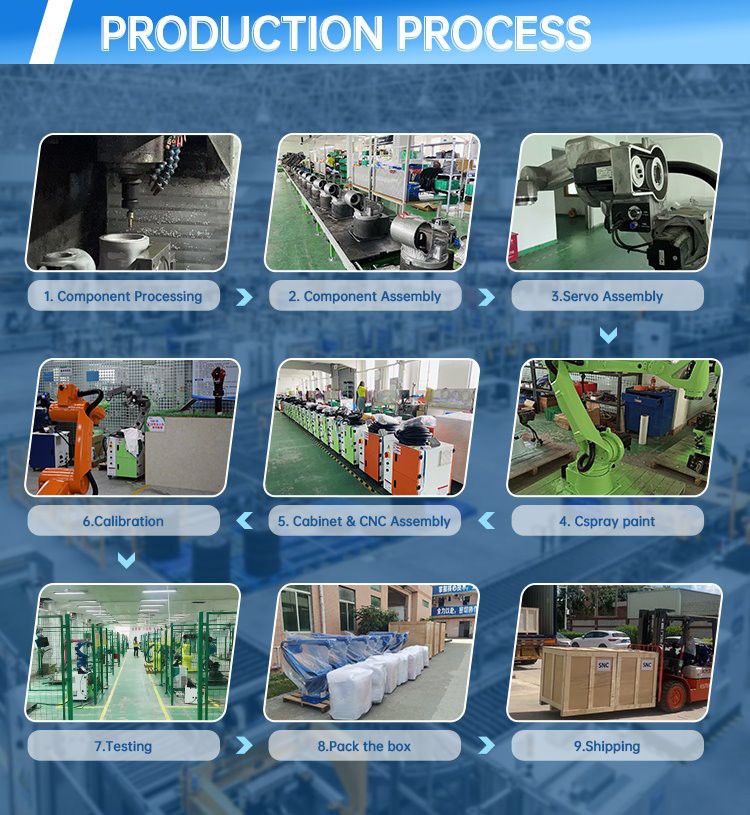

1) Suitable for multiple increments; absolute servo. Improved computer bus connection ensures reliability and practicability.

2) Open structure for synchronization of international technology and extension of functions. Industrial standards & reliable stability.

3) Software PLC functions facilitate logic control. Process functions make programming easy.

Q1: What do I provide for custom an inflatable arch?

A: Well,at first, we have to confirm basically information, such as size material,printing or notartight or cold air. If you have no idea about any of these information,don't worry,every sales will provide a solution after discuss with designer and factory director.

Q2: Are there any fixtures for the robot?

A: Yes, we have a team of 350 engineers who professionally design robot fixtures, such as welding positioners, welding fixtures, suction cups, hand grips, conveyor lines, feeding bins and other supporting automated tooling.

Q3: What does your factory produce ?

A: We produce and export all kinds of automatic welding machine all kinds of robots. We also

manufacture and export all kinds of automation CNC systems, motors and drives.

If you have any questions, pls feel free to contact me below.